Nano microcapsule preservative, and preparation method and application thereof

A technology of nano-microcapsules and antistaling agents, applied in the field of nano-microcapsules antistaling agents and its preparation, can solve problems that have not yet been reported in research reports, and achieve the effects of being friendly to the human body and the environment, good thermal stability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

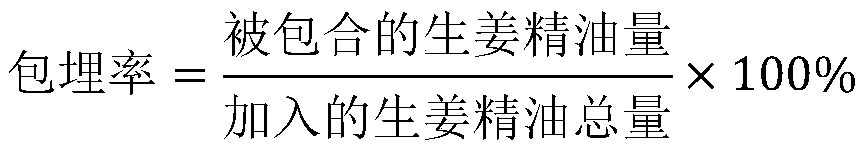

Method used

Image

Examples

Embodiment 1

[0030] Formula and preparation of nano-microcapsule preservative (1)

[0031] 1. Add 3 g of nano-SiO 2 Dissolve in 1L of distilled water, then add 10g of sodium alginate and 2g of konjac gum, put the prepared solution in a constant temperature water bath, bathe in a constant temperature water bath at 70°C for 20 minutes, stir to make it completely dissolve, after cooling, make up the remaining water, A composite wall material is prepared.

[0032] 2. Add 6 g of ginger essential oil and 3 g of monoglyceride to the prepared composite wall material, stir magnetically for 20 minutes, and homogenize the emulsion under high pressure for 3 times at a homogenization pressure of 35 MPa. After homogenization, the nano-essential oil microcapsule preservative is obtained.

Embodiment 2

[0034] Formula and preparation of nano-microcapsule preservative (2)

[0035] 1. Mix 6g of nano-SiO 2 Dissolve in 1L of distilled water, then add 20g of sodium alginate and 4g of konjac gum, put the prepared solution in a constant temperature water bath, bathe in a constant temperature water bath at 70°C for 20 minutes, stir to make it completely dissolve, after cooling, make up the remaining water, A composite wall material is prepared.

[0036] 2. Add 12g of ginger essential oil and 5g of monoglyceride to the prepared composite wall material, stir magnetically for 20min, and homogenize the emulsion under high pressure 3 times at a homogenization pressure of 35MPa. After homogenization, the nano-essential oil microcapsule preservative is obtained.

Embodiment 3

[0038] Formulation and preparation of nano-microcapsule preservative (3)

[0039] 1. Add 4 g of nano-SiO 2 Dissolve in 1L of distilled water, then add 15g of sodium alginate and 3g of konjac gum, put the prepared solution in a constant temperature water bath, bathe in a constant temperature water bath at 70°C for 20 minutes, stir to dissolve completely, after cooling, make up the remaining water, A composite wall material is prepared.

[0040] 2. Add 8 g of ginger essential oil and 4 g of monoglyceride to the prepared composite wall material, stir magnetically for 20 minutes, and homogenize the emulsion under high pressure for 3 times at a homogenization pressure of 35 MPa. After homogenization, the nano-essential oil microcapsule preservative is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com