Application of Fullerene Derivatives as Electrolyte Additives and Corresponding Metal Batteries

A technology of fullerene derivatives and electrolyte additives, which is applied in secondary batteries, circuits, electrical components, etc., can solve the problems of high production cost and difficult application, so as to reduce lithium consumption, reduce dendrites, reduce The effect of the formation of lithium dendrites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

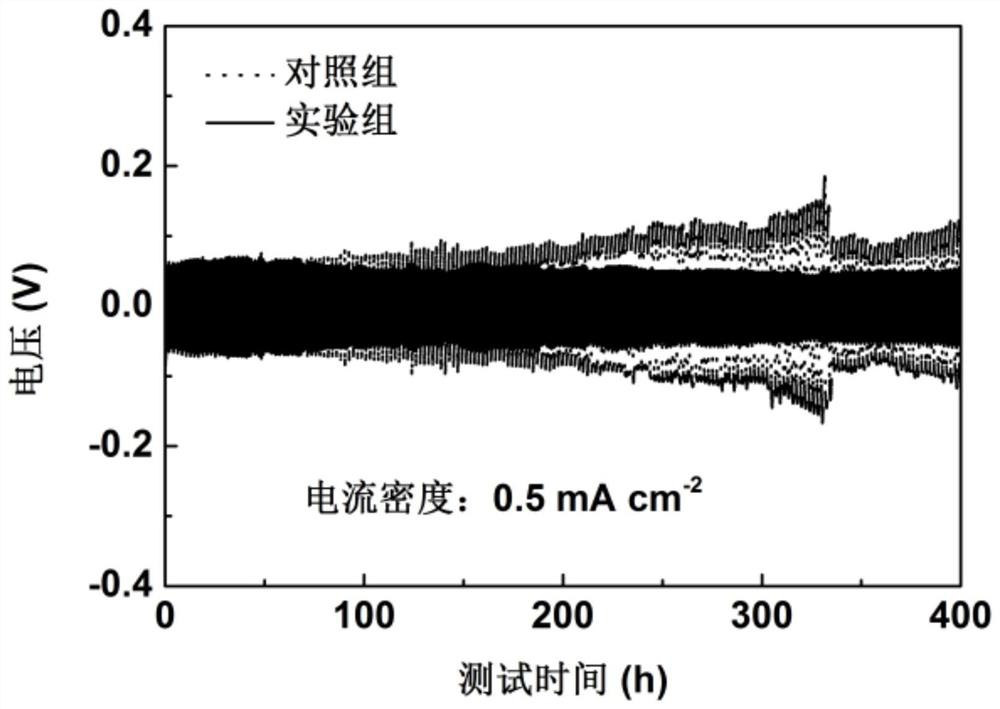

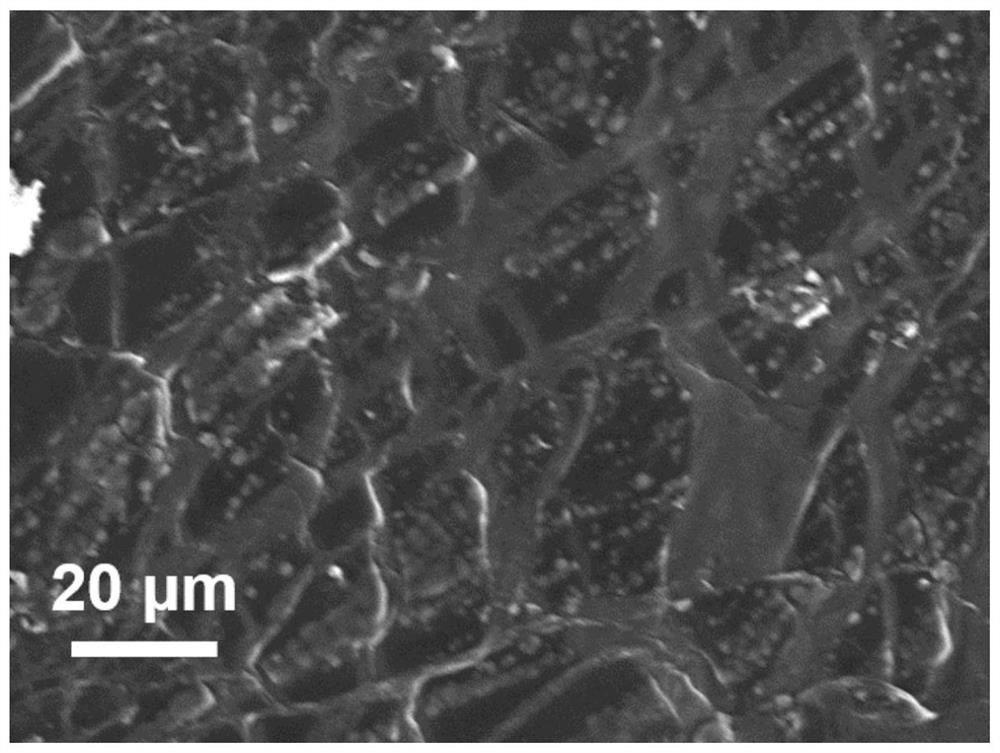

[0028]Dissolve 1mM fullerene polynitrate (C60(NO2)n) in 1M lithium hexafluorophosphate solution of ethylene carbonate and diethyl carbonate (volume ratio 1:1), stir completely until dissolved, and use the electrolyte Assemble lithium-lithium symmetrical batteries together with lithium sheets and diaphragms, and at 0.5mA cm -2 Under the current density of the cycle test, such as figure 1 As shown, in the experimental group using the ester electrolyte with additives, the symmetrical battery can cycle stably for more than 400 hours and maintain a low overpotential, while the control group has a large overpotential and cannot stabilize Cycle (the electrolyte in the control group is simply 1M lithium hexafluorophosphate ethylene carbonate and diethyl carbonate solution, the volume ratio is 1:1, and other battery structures and parameter settings remain unchanged). The symmetrical battery after the above cycle is disassembled, and the lithium sheet is taken out, such as figure 2 ...

Embodiment 2

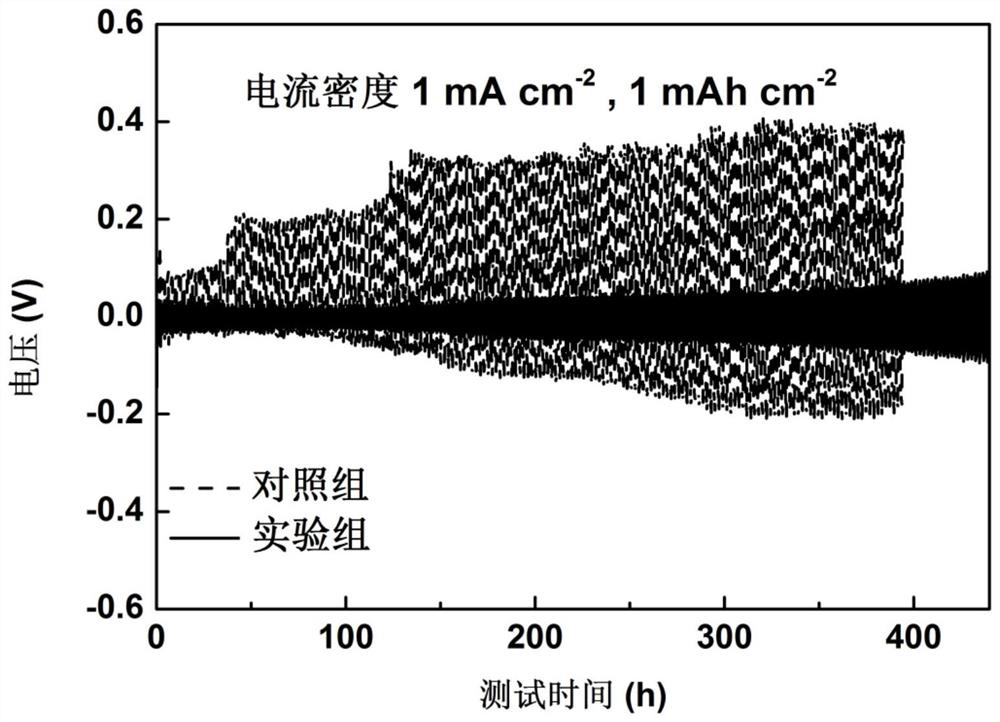

[0030] Dissolve 1 mM fullerene fullerene polynitrate (C60(NO2)n) in 1 M dioxolane and ethylene glycol dimethyl ether solution of lithium bistrifluoromethanesulfonimide (volume ratio of 1 : 1), after stirring completely until dissolved, use the electrolyte, lithium sheet and diaphragm to assemble a lithium-lithium symmetrical battery, and use the electrolyte at 1mA cm -2 Cyclic tests are carried out at current densities such as image 3 As shown, in the experimental group using the ether electrolyte with additives, the symmetrical battery can cycle stably for more than 400 hours, while the control group has a large overpotential and cannot cycle stably (the electrolyte in the control group It is simply a 1M dioxolane and ethylene glycol dimethyl ether solution of lithium bistrifluoromethylsulfonimide, the volume ratio is 1:1, and other battery structures and parameter settings remain unchanged). This shows that the additive also has a significant effect in the ether electrolyt...

Embodiment 3

[0032] The selected additive type is fullerene polychloride (C60Cln), and the selected electrolytic solution is dioxolane and ethylene glycol dimethyl ether solution (volume ratio of 1M bistrifluoromethylsulfonimide lithium) 1:1), and other conditions are the same as implementation 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com