Application of cobalt-iron alloy in magnetic capacitors, magnetic capacitor unit, magnetic capacitor device and preparation method thereof

A technology of cobalt-iron alloy and magnetic capacitance, which is applied in the field of capacitors, can solve the problems of undetectable capacitance, etc., and achieve the effects of prolonged electrode life, excellent magnetic properties, and good magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

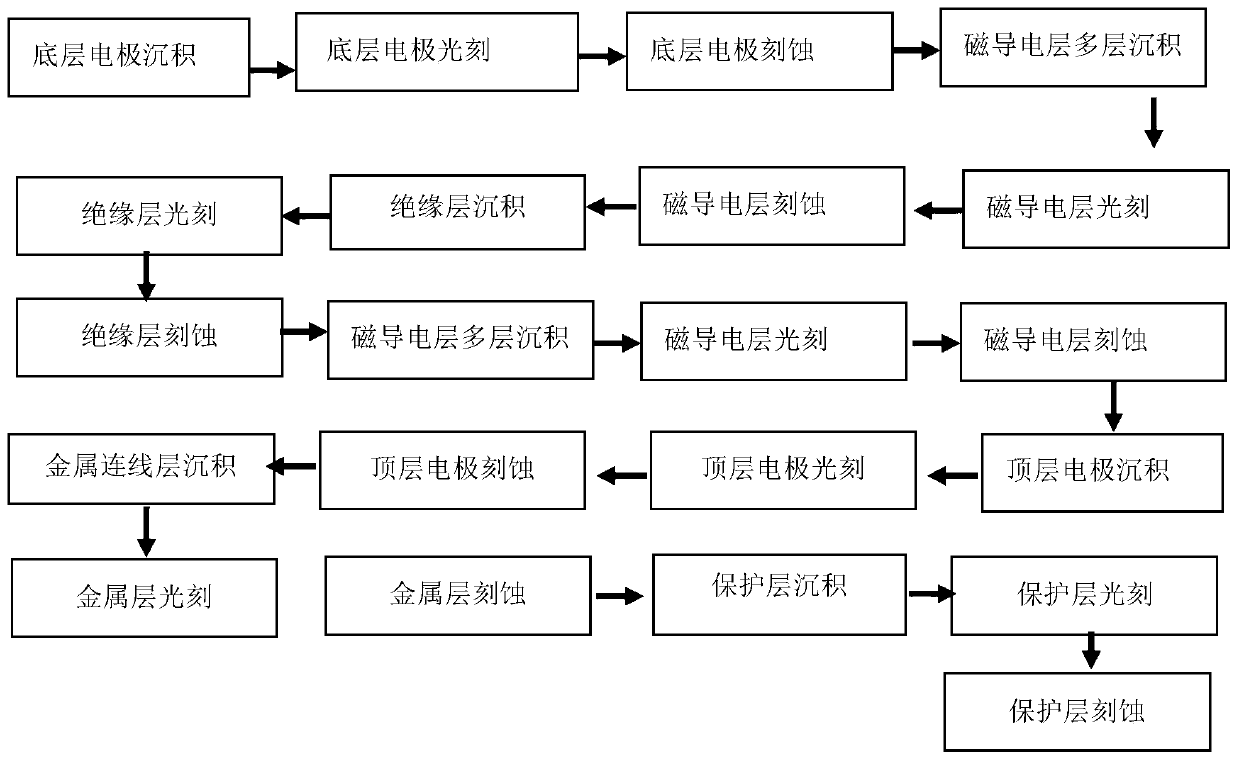

Image

Examples

Embodiment 1

[0064] Embodiment 1 A magnetic capacitance unit

[0065] A magnetocapacitive unit such as figure 1 As shown, it is covered on the Si substrate 6, and includes from top to bottom: top electrode layer 1, magnetically conductive layer 2, insulating layer 3, magnetically conductive layer 4, and bottom electrode layer 5. The composition and thickness of each layer are as follows 1.

[0066] Table 1 Structural design of magnetic capacitance unit

[0067]

[0068]

[0069] Among them, the magnetoconductive layer 2 and the magnetoconductive layer 4 are composed of multi-layer nano-scale magnetic films with a total thickness of 150-250nm; the magnetic films of each layer are deposited by magnetron sputtering coating with a cobalt-iron alloy as the target material, and the thickness is 5-25 nm; in the cobalt-iron alloy target used, the atomic ratio of cobalt to iron is 6.5-7.2:3.5-2.8, preferably 7:3.

[0070] Preferably, the length of the magnetic capacitance unit is 1.0-2.0 μ...

Embodiment 2

[0072] Embodiment 2 A magnetic capacitance unit

[0073] Compared with Example 1, the difference is that the structure of the magnetoconductive layer is shown in Table 2 below. The magnetoconductive layer 2 and the magnetoconductive layer 4 are respectively composed of multilayer nanoscale CoFeB magnetic films, which are CoFeB synthesized by CoFe and B. The target is a deposited film with a thickness of 5-25nm deposited by magnetron sputtering coating.

[0074] The structure design of the magnetoconductive layer of table 2 embodiment 2

[0075]

Embodiment 3

[0076] Embodiment 3 A magnetic capacitance unit

[0077] Compared with Example 1, the difference is that the structures of the magnetoconductive layer 2 and the magnetoconductive layer 4 are shown in Table 3 below, which are formed by magnetron sputtering coating deposition using CoFe, TaO and CoFeB respectively.

[0078] The structural design of the magnetoconductive layer of embodiment 3

[0079]

[0080]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com