Method for measuring titanium content in nickel-titanium-niobium shape memory alloy

A technology of memory alloy and determination method, which can be used in color/spectral characteristic measurement, material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions, etc. It can solve the problem of inability to accurately measure the shape of NiTi Memory alloy has high titanium content, cannot meet the needs of R & D and production, and the cost of titanium content detection is high, so as to achieve the effect of optimizing reagent and dosage parameters, shortening time impact, and saving testing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The determination method of titanium content in nickel-titanium-niobium shape memory alloy, the implementation method is as follows:

[0047] Step 1: Weigh 0.1000g of the sample into a 250mL beaker, add 25mL of sulfuric acid (1+1) and heat until the sample is completely dissolved to form salts, continue heating until sulfuric acid fumes are emitted, remove and cool to room temperature.

[0048] Step 2: Add water to the beaker in step 1, heat to dissolve the salts, and transfer to a 250mL volumetric flask to obtain a test solution.

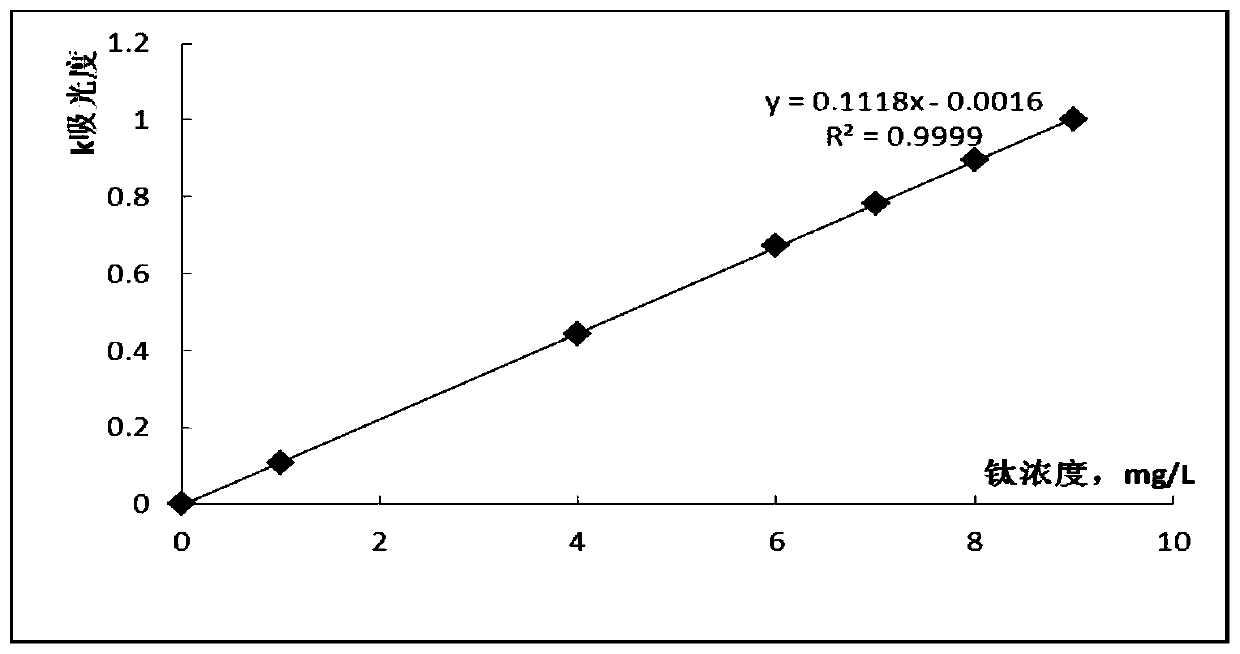

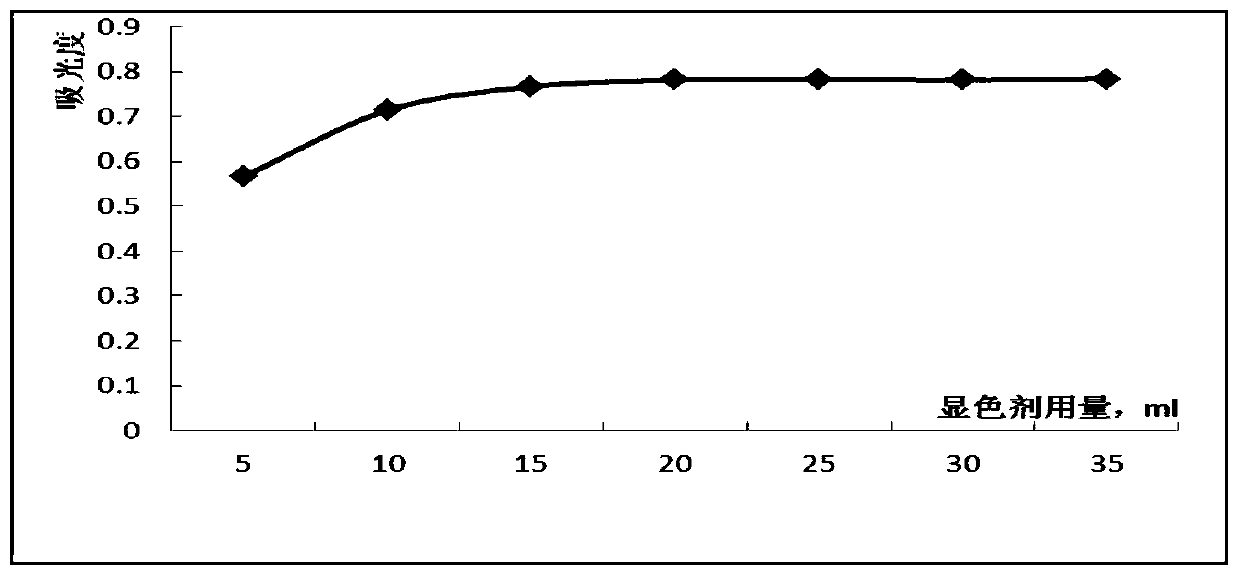

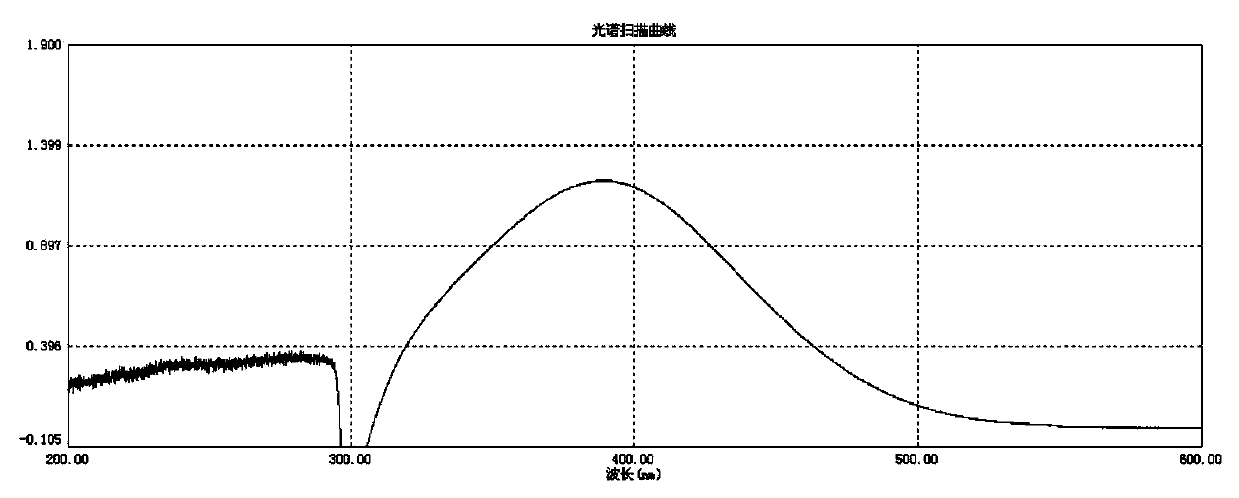

[0049] Step 3: Take 10.0mL of the test solution in step 2 into a 200mL volumetric flask, add 10mL of hydrochloric acid solution, 5mL of ascorbic acid solution, leave for 5min, add 25mL of diantipyridine methane hydrochloride solution, dilute with water, place for 15min, at the wavelength Use a 1cm cuvette to measure the absorbance at 460nm and use a 1cm cuvette for zero adjustment, and check the quality of titanium from the working curve acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com