Sheath-core composite monofilament and preparing method and application thereof

A composite monofilament and composite spinning technology, which is applied in the field of skin-core composite monofilament and its preparation, can solve the problems of high cost and high specific weight, and achieve the effects of preventing skin breakage, high mechanical strength, and good interface compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] On the other hand, the present invention provides a method for preparing the above-mentioned sheath-core composite monofilament, which includes the following steps:

[0055] The skin layer raw material and the core layer raw material are respectively melted and pressurized, and then subjected to spinning compound to obtain the skin-core composite monofilament.

[0056] Specifically, in some preferred embodiments of the present invention, the preparation method includes the following steps:

[0057] Provide horizontal heald wire drawing equipment, the horizontal heddle wire drawing equipment includes a skin extruder, a core extruder and a skin-core dual-channel composite spinning die;

[0058] The skin material placed in the skin extruder enters the skin channel of the composite spinning die after being melted, extruded and metered; the core material placed in the core extruder is melted, extruded and metered Enter the core layer channel of the composite spinning die;

[0059] Th...

Embodiment 1

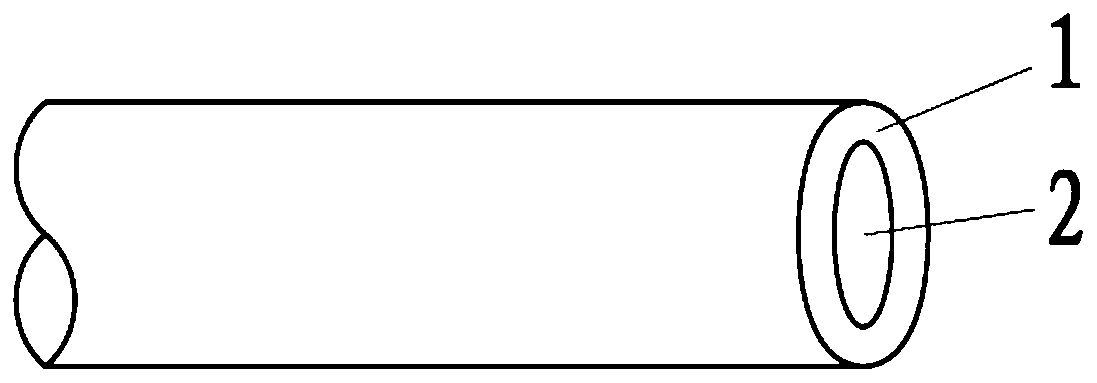

[0066] Such as figure 1 As shown, this embodiment is a sheath-core composite monofilament with a wire diameter of 0.05 mm, consisting of a skin layer and a core layer wrapped in the sheath, and the weight ratio of the sheath layer to the core layer of the sheath-core composite monofilament is 5: 5. The skin layer is made of mixed raw materials of HDPE and LLDPE with a weight ratio of 9:1, and the core layer is made of PP raw materials. The interface of the sheath-core composite monofilament is circular, and the whole is fibrous.

[0067] Among them, the melt index of HDPE is 0.7g / 10min and the density is 0.943g / cm 3 ; The melt index of LLDPE is 1.5g / 10min, and the density is 0.918g / cm 3 ; PP's melt index is 3g / 10min, density is 0.895g / cm 3 .

[0068] The specific preparation process of the sheath-core composite monofilament is as follows:

[0069] 1) Provide horizontal heald wire drawing equipment, which includes a skin extruder, a core extruder and a skin-core dual-channel compos...

Embodiment 2

[0075] This embodiment is a sheath-core composite monofilament. The difference between the sheath-core composite monofilament and Example 1 lies in that the weight ratio of the skin layer to the core layer of the sheath-core composite monofilament in this embodiment is 3:7. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com