A kind of q345r steel plate with excellent performance under high temperature simulated post-weld heat treatment conditions and its manufacturing method

A post-weld heat treatment and manufacturing method technology, which is applied in the field of steel plate manufacturing, can solve problems such as poor performance matching and small steel plate thickness, achieve high strength and impact toughness, and prevent grain coarsening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

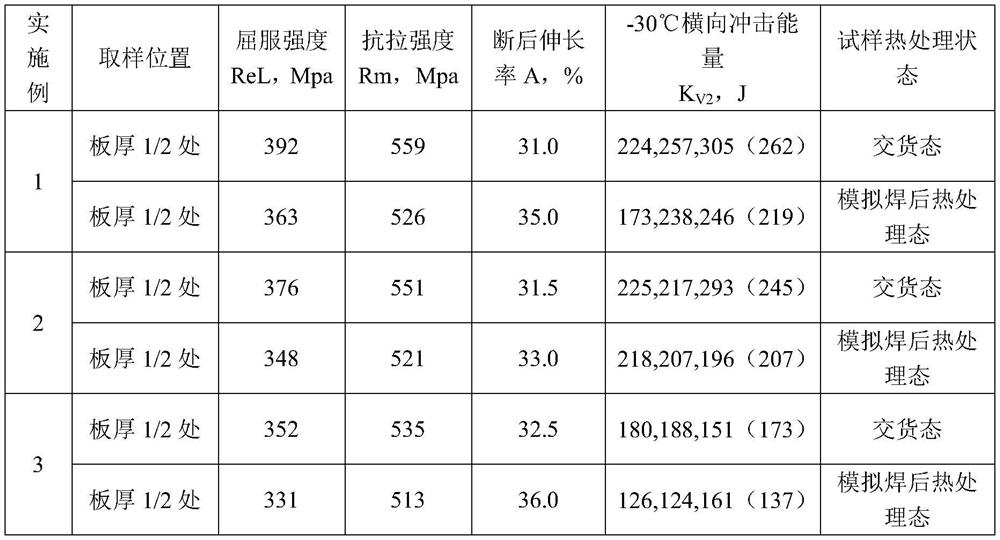

Examples

Embodiment 1

[0041] The thickness of the steel plate in this embodiment is 20mm, and its chemical composition is calculated by weight percentage: its chemical composition is calculated by weight percentage: C: 0.165%, Si: 0.41%, Mn: 1.42%, P: 0.006%, S: 0.001 %, Al: 0.032%, Nb: 0.030%, Ti: 0.015%, Ni: 0.22%, Cu: 0.20%, the balance is Fe and unavoidable impurity elements, carbon equivalent Ceq: 0.435%, carbon equivalent calculation formula It is: Ceq=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15.

[0042] The manufacturing process of the steel plate is as follows:

[0043] The continuous casting slab with a section of 370mm is used as the blank, and the specific operation of the main process is as follows:

[0044] 1) Smelting process

[0045] Smelting raw materials are sequentially subjected to KR molten iron pretreatment, converter smelting, LF refining, RH vacuum degassing treatment and slab continuous casting process. Slagging treatment after converter smelting, calcium treatment after LF refining, ...

Embodiment 2

[0054] The thickness of the steel plate in this embodiment is 50mm, and its chemical composition is calculated by weight percentage: C: 0.16%, Si: 0.42%, Mn: 1.42%, P: 0.005%, S: 0.0008%, Al: 0.034%, Nb: 0.032%, Ti: 0.016%, Ni: 0.25%, Cu: 0.21%, the balance is Fe and unavoidable impurity elements, carbon equivalent Ceq: 0.44%, carbon equivalent calculation formula is: Ceq=C+Mn / 6 +(Cr+Mo+V) / 5+(Ni+Cu) / 15.

[0055] The manufacturing process of the steel plate is as follows:

[0056] The continuous casting slab with a section of 450mm is used as the blank, and the specific operation of the main process is as follows:

[0057] 1) Smelting process

[0058] Smelting raw materials are sequentially subjected to KR molten iron pretreatment, converter smelting, LF refining, RH vacuum degassing treatment and slab continuous casting process. Slagging treatment after converter smelting, calcium treatment after LF refining, RH vacuum treatment with a limit vacuum degree of 60Pa, a vacuum ...

Embodiment 3

[0067] The thickness of the steel plate in this embodiment is 100mm, and its chemical composition is calculated by weight percentage: C: 0.17%, Si: 0.45%, Mn: 1.45%, P: 0.005%, S: 0.0005%, Al: 0.035%, Nb: 0.035%, Ti: 0.014%, Ni: 0.23%, Cu: 0.22%, the balance is Fe and unavoidable impurity elements, carbon equivalent Ceq: 0.445%, carbon equivalent calculation formula is: Ceq=C+Mn / 6+ (Cr+Mo+V) / 5+(Ni+Cu) / 15.

[0068] The manufacturing process of the steel plate is as follows:

[0069] The continuous casting slab with a section of 450mm is used as the blank, and the specific operation of the main process is as follows:

[0070] 1) Smelting process

[0071] Smelting raw materials are sequentially subjected to KR molten iron pretreatment, converter smelting, LF refining, RH vacuum degassing treatment and slab continuous casting process. Slagging treatment after converter smelting, calcium treatment after LF refining, RH vacuum treatment with a limit vacuum degree of 60Pa, a vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com