Liquid metal material for noise reduction in nuclear reactor environment and processing technology thereof

A liquid metal and nuclear reactor technology, applied in the field of alloys, can solve the problems of increasing the leakage of nuclear products, achieve the effects of attenuating rays, realizing degrees of freedom, and excellent shielding materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

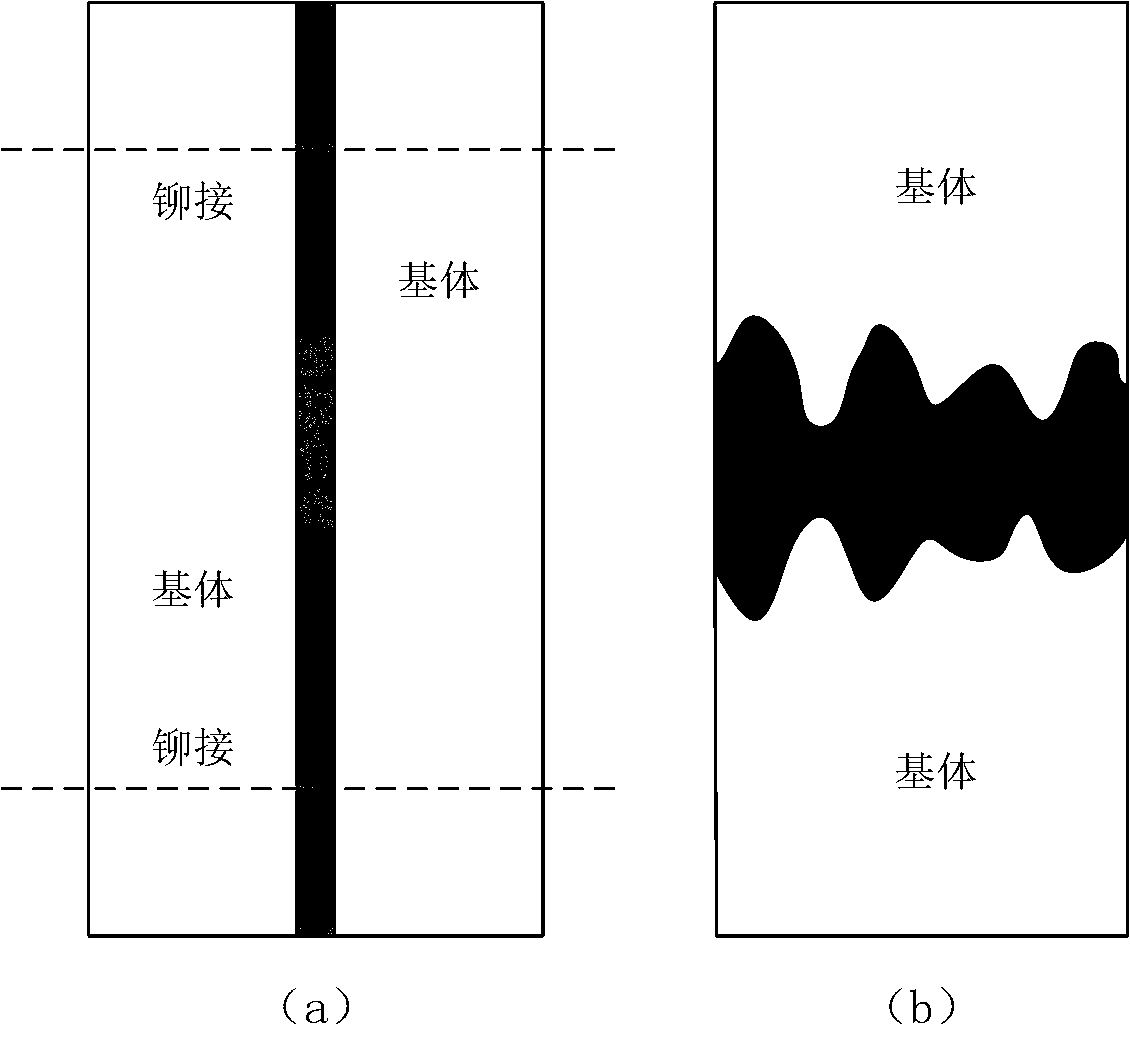

Image

Examples

Embodiment 1

[0018] A liquid metal material for reducing noise in a nuclear reactor environment and a processing technology thereof. In terms of weight percentage, the alloy composition is: Se: 0.1wt.%, Sb: 8.0wt.%, In: 21.0wt.%, V: 0.5wt.%, Ag: 1.5wt.%, Pb: 12.0wt. %, Cd: 5.0wt.%, the balance is tin.

[0019]The above-mentioned liquid metal material for noise reduction in a nuclear reactor environment and its processing technology include the following processing and use steps: (a) After the alloy is configured according to the required composition, it is put into an induction furnace for smelting, and magnesium oxide is used to Or the alumina crucible is smelted under the protection of argon; after 10 minutes of heat preservation at 500 degrees, the alloy melt is fully stirred evenly by electromagnetic stirring, and the dross on the surface of the melted alloy melt is scraped off, poured into an iron mold and cast into a Rod shape (about 200 mm in length, 8 mm in width, and about 3 mm i...

Embodiment 2

[0022] A liquid metal material for reducing noise in a nuclear reactor environment and a processing technology thereof. In terms of weight percentage, the alloy composition is: Se: 0.2wt.%, Sb: 15.0wt.%, In: 25.0wt.%, V: 1.0wt.%, Ag: 2.0wt.%, Pb: 15.0wt. %, Cd: 10.0wt.%, the balance is tin.

[0023] The above-mentioned liquid metal material for noise reduction in a nuclear reactor environment and its processing technology include the following processing and use steps: (a) After the alloy is configured according to the required composition, it is put into an induction furnace for smelting, and magnesium oxide is used to Or melt the alumina crucible under the protection of argon; heat the alloy melt at 520 degrees for 10 minutes and use electromagnetic stirring to fully stir the alloy melt evenly, scrape off the dross on the surface of the melted alloy melt, pour it into an iron mold and cast it into a Rod shape (about 300 mm in length, 10 mm in width, and about 5 mm in thickn...

Embodiment 3

[0026] A liquid metal material for reducing noise in a nuclear reactor environment and a processing technology thereof. In terms of weight percentage, the alloy composition is: Se: 0.2wt.%, Sb: 12.0wt.%, In: 22.0wt.%, V: 0.8wt.%, Ag: 1.8wt.%, Pb: 13.0wt. %, Cd: 6.0wt.%, the balance is tin.

[0027] The above-mentioned liquid metal material for noise reduction in a nuclear reactor environment and its processing technology include the following processing and use steps: (a) After the alloy is configured according to the required composition, it is put into an induction furnace for smelting, and magnesium oxide is used to Or melt the alumina crucible under the protection of argon gas; heat the alloy melt at 530 degrees for 10 minutes and use electromagnetic stirring to fully stir the alloy melt evenly, scrape off the dross on the surface of the melted alloy melt, pour it into an iron mold and cast it into a Rod shape (about 250 mm in length, 9 mm in width, and about 4 mm in thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com