Lactobacillus acetotolerans and application thereof

A technology of lactobacilli and strains, which is applied in the field of microbial application and traditional food brewing, can solve the problems that lactic acid bacteria and methods are difficult to achieve the expected results, the inoculation amount of lactic acid bacteria is high, and it is not suitable for industrial application. application, well tolerated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Isolation and Identification of Example 1 Strain HSCY 2035

[0033] 1. Isolation of strains

[0034] Collect aged rice vinegar, aged apple vinegar, aged persimmon vinegar and other aged liquid fermented vinegar samples, take 25ml of each sample and add to 225ml of sterilized normal saline, shake well and add 1ml to 9ml of sterile normal saline , after mixing evenly on a vortex mixer, take 1ml of the diluted solution and add it to 9ml of normal saline, and so on. Select 3 appropriate concentrations and spread them sequentially on the MRS solid plate added with 3% (w / v) acetic acid (acid added after sterilization), and culture at 30°C for 5-10 days.

[0035] 2. Strain purification

[0036] According to the size, color, luster, transparency, etc. of the microbial colonies, the colonies on the separation plate were picked, and purified twice on the MRS solid plate containing 3% (w / v) acetic acid by streaking.

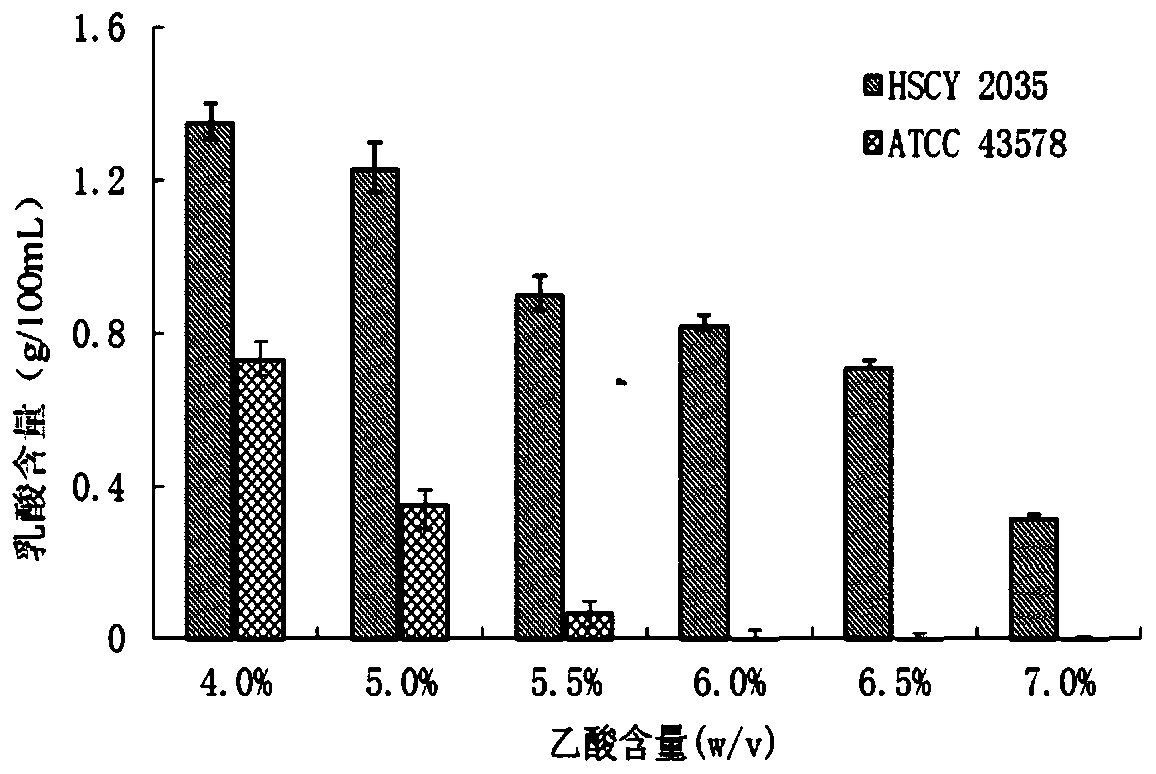

[0037] 3. Strain screening

[0038] The purified strains we...

Embodiment 2

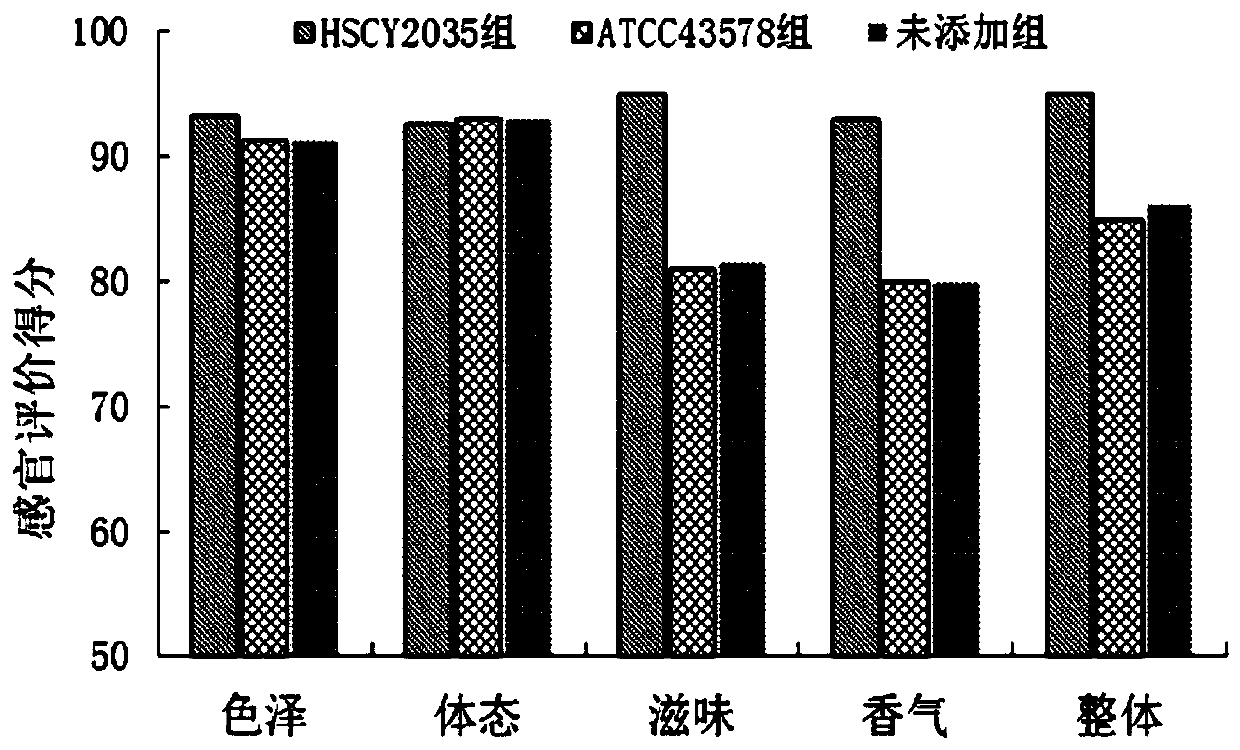

[0049] Application of Example 2 Strain HSCY 2035 in Rice Vinegar Brewing

[0050] 1. Preparation of strain seed solution

[0051] Preparation of primary seed liquid: according to the inoculum amount of 5% (v / v), the acid-resistant Lactobacillus HSCY2035 bacterial liquid in the logarithmic phase of growth and the acid-resistant Lactobacillus ATCC 43578 bacterial liquid in the logarithmic phase of growth were inoculated into 1L containing 3 % (w / v) acetic acid liquid MRS medium, 30 ° C closed static culture for 5 to 7 days to obtain the first-class seed liquid of Lactobacillus acid-resistant HSCY 2035 and the first-class seed liquid of Lactobacillus acid-resistant ATCC 43578 respectively.

[0052] Preparation of secondary seed liquid: according to the inoculum size of 5% (v / v), the primary seed liquid of Lactobacillus acid-resistant HSCY 2035 and the primary seed liquid of Lactobacillus acid-resistant ATCC 43578 were respectively inserted in 20L culture fluid (cultivation The l...

Embodiment 3

[0062] Application of Example 3 strain HSCY 2035 in apple cider vinegar brewing

[0063] 1. Preparation of strain seed solution

[0064] Preparation of primary seed liquid: according to the inoculum amount of 5% (v / v), the acid-resistant Lactobacillus HSCY2035 bacterial liquid in the logarithmic phase of growth and the acid-resistant Lactobacillus ATCC 43578 bacterial liquid in the logarithmic phase of growth were inoculated into 1L containing 3 % (w / v) acetic acid liquid MRS medium, 30 ° C closed static culture for 5 to 7 days to obtain the first-class seed liquid of Lactobacillus acid-resistant HSCY 2035 and the first-class seed liquid of Lactobacillus acid-resistant ATCC 43578 respectively.

[0065] Preparation of secondary seed liquid: according to the inoculum size of 5% (v / v), the primary seed liquid of Lactobacillus acid-resistant HSCY 2035 and the primary seed liquid of Lactobacillus acid-resistant ATCC 43578 were inserted into 20L culture fluid respectively (culture f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com