High-hardness heat-resistant intumescent fireproof coating and preparation method thereof

A fire retardant coating, intumescent technology, applied in the field of flame retardant, can solve the problems of large usage, thick coating, affecting use, etc., to achieve the effects of weakened moisture absorption, excellent flow performance, and improved fire resistance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

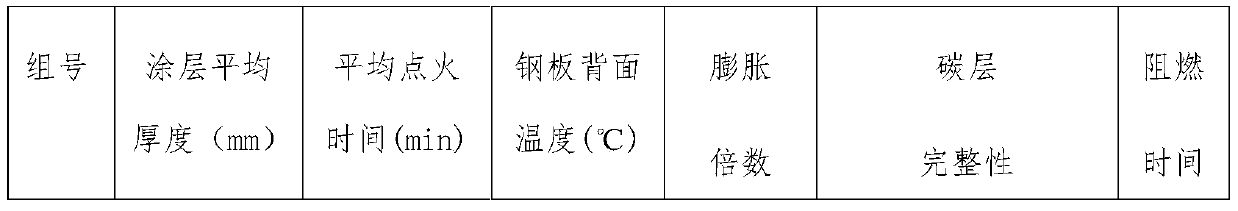

Image

Examples

preparation example Construction

[0014] A preparation method of a high-hardness heat-resistant expansion type fireproof coating, comprising: (1) preparation of modified aluminum dihydrogen phosphate: adding dropwise a silane coupling agent hydrolyzed by alcohol to aluminum dihydrogen phosphate. It should be noted that, in this embodiment, the alcohol hydrolysis of the silane coupling agent includes: using a hydroalcoholic solution whose mass is twice that of the silane coupling agent to perform alcohol hydrolysis on the silane coupling agent. Wherein, the mass ratio of water and alcohol in the hydroalcoholic solution is 1:1. To play a role in ensuring the stability of the solution after silane hydrolysis.

[0015] In this embodiment, the silane coupling agent further includes at least one of KH560, phenyltrimethoxysilane and A171. It should be noted that the inventors found that the special functional groups of the above-mentioned silane coupling agents have a certain activity, and the phenyl group containin...

Embodiment 1

[0023] This embodiment provides a method for preparing a high-hardness heat-resistant expansion type fireproof coating, including:

[0024] (1) Preparation of modified aluminum dihydrogen phosphate: Weigh a certain amount of aluminum dihydrogen phosphate, add 2% alcohol-hydrolyzed phenyltrimethoxysilane dropwise to it under stirring in a kneader, then heat up to 80°C and stir After reacting for 1 h, 0.5% hydrogen-containing silicone oil was added dropwise, and the temperature was raised to 150° C. and stirred for 0.5 h.

[0025] (2) Preparation of fire retardant coating: Take 25 parts of distilled water, add 0.5 parts of dispersant, 4 parts of titanium dioxide, 0.5 parts of leveling agent, 30 parts of composite flame retardant (among which modified Aluminum dihydrogen phosphate is 2.7 parts, ternary system is 27.3 parts), increase the stirring speed to 2000r / min, stir for 20min, then reduce the speed to 1000r / min, add 39.5 parts of acrylic acid emulsion, 0.5 parts of defoamer,...

Embodiment 5

[0039] This embodiment provides a method for preparing a high-hardness heat-resistant expansion type fireproof coating, including:

[0040] (1) Preparation of modified aluminum dihydrogen phosphate: Weigh a certain amount of aluminum dihydrogen phosphate, add 2% alcohol-hydrolyzed phenyltrimethoxysilane dropwise to it under stirring in a kneader, then heat up to 80°C and stir After reacting for 1 h, 0.5% hydrogen-containing silicone oil was added dropwise, and the temperature was raised to 150° C. and stirred for 0.5 h.

[0041] (2) Preparation of fire retardant coating: Take 25 parts of distilled water, add 0.5 parts of dispersant, 4 parts of titanium dioxide, 0.5 parts of leveling agent, 30 parts of composite flame retardant (among which modified 7 parts of permanent aluminum dihydrogen phosphate, 23 parts of ternary system), increase the stirring speed to 2000r / min, stir for 20min, then reduce the speed to 1000r / min, add 39.5 parts of acrylic emulsion, 0.5 parts of defoamer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com