Snow tire, snow tire tread rubber composition and rubber composition mixing method

A rubber composition and a technology for snow tires, which are applied in the field of mixing snow tires and snow tire tread rubber compositions and rubber compositions, can solve the problem that the tire's low-temperature grip performance decreases and the tread rubber content decreases. Tread hardness, migration and other issues, to improve the degree of hardening, improve dispersion, increase cold resistance and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

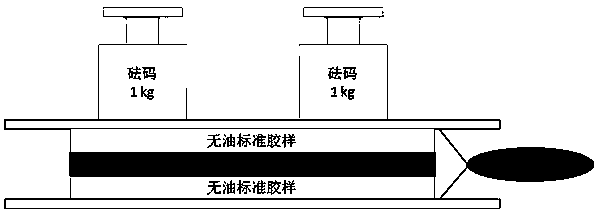

Method used

Image

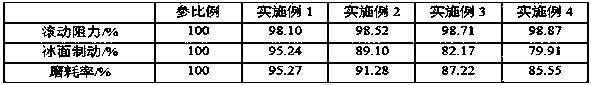

Examples

Embodiment 1

[0038] Raw material composition: 36.0 parts of liquid polybutadiene rubber, 38.0 parts of natural rubber, 52.0 parts of rare earth butadiene, 10.0 parts of solution polystyrene butadiene rubber, 75.0 parts of white carbon black 1165 MP, 10.0 parts of N134 carbon black, 6.0 parts of silane coupling Agent TESPD, 25.0 parts of environmentally friendly aromatic oil, 2.5 parts of anti-aging agent 6PPD, 1.0 parts of anti-aging agent TMQ, 2.0 parts of microcrystalline wax, 2.5 parts of zinc oxide, 1.5 parts of stearic acid, 1.0 parts of a mixture of saturated and unsaturated fatty acid zinc, 2.0 Parts of sulfur, 3.0 parts of accelerator CZ, 2.5 parts of accelerator DPG.

[0039] Among them, the combined styrene in solution-polymerized styrene-butadiene accounts for 21% of the total weight of the polymer, and vinyl accounts for 68% of the total weight of butadiene. Saturated and unsaturated fatty acid zinc is plasticizer A, and carbon black 1165MP is a product of Solvay. N134 carbon ...

Embodiment 2

[0041] Raw material composition: 42.0 parts of liquid polybutadiene rubber, 38.0 parts of natural rubber, 52.0 parts of rare earth butadiene, 10.0 parts of solution polystyrene butadiene rubber, 75.0 parts of white carbon black 1165 MP, 10.0 parts of N134 carbon black, 6.0 parts of silane coupling Agent TESPD, 22.0 parts of environmentally friendly aromatic oil, 2.5 parts of anti-aging agent 6PPD, 1.0 parts of anti-aging agent TMQ, 2.0 parts of microcrystalline wax, 2.5 parts of zinc oxide, 1.5 parts of stearic acid, 1.0 parts of a mixture of saturated and unsaturated fatty acid zinc, 2.0 Parts of sulfur, 3.0 parts of accelerator CZ, 2.5 parts of accelerator DPG.

[0042] Among them, the combined styrene in solution-polymerized styrene-butadiene accounts for 21% of the total weight of the polymer, and vinyl accounts for 68% of the total weight of butadiene. Saturated and unsaturated fatty acid zinc is plasticizer A, and carbon black 1165MP is a product of Solvay. N134 carbon ...

Embodiment 3

[0044] Raw material composition: 47.0 parts of liquid polybutadiene rubber, 38.0 parts of natural rubber, 52.0 parts of rare earth butadiene, 10.0 parts of solution polystyrene butadiene rubber, 75.0 parts of white carbon black 1165 MP, 10.0 parts of N134 carbon black, 6.0 parts of silane coupling Agent TESPD, 20.0 parts of environmentally friendly aromatic oil, 2.5 parts of anti-aging agent 6PPD, 1.0 parts of anti-aging agent TMQ, 2.0 parts of microcrystalline wax, 2.5 parts of zinc oxide, 1.5 parts of stearic acid, 1.0 parts of a mixture of saturated and unsaturated fatty acid zinc, 2.0 Parts of sulfur, 3.0 parts of accelerator CZ, 2.5 parts of accelerator DPG.

[0045] Among them, the combined styrene in solution-polymerized styrene-butadiene accounts for 21% of the total weight of the polymer, and vinyl accounts for 68% of the total weight of butadiene. Saturated and unsaturated fatty acid zinc is plasticizer A, and carbon black 1165MP is a product of Solvay. N134 carbon bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com