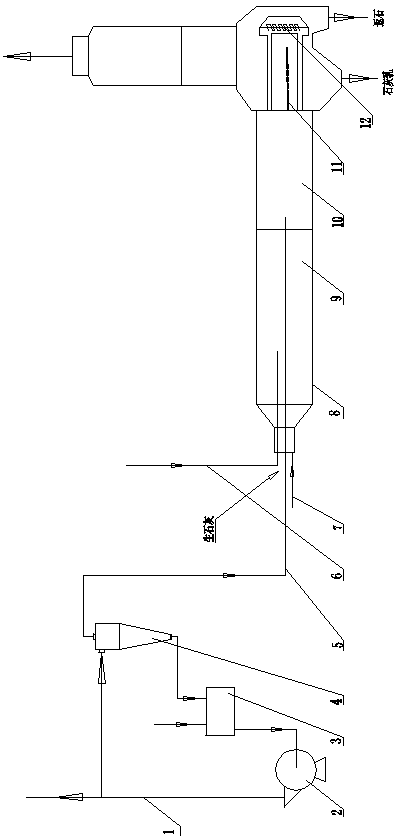

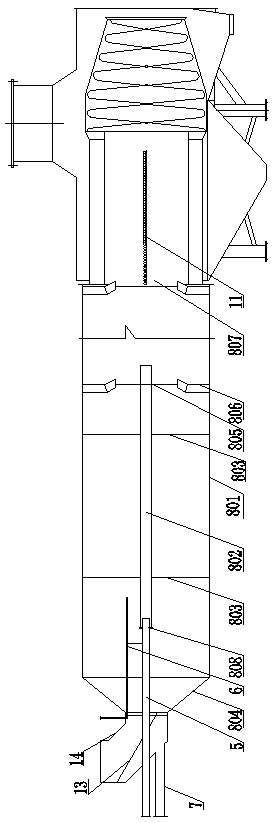

Production device and production process for preparing lime milk from ammonia distillation waste liquid

The technology of ammonia distillation waste liquid and production device is applied in the field of production device and production technology for preparing lime milk from ammonia steam waste liquid, and can solve the problems of low concentration of ash milk, clogging of screen mesh, slowing down of lime digestion speed, etc. Achieve the effect of saving water resources and energy consumption and reducing digestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Evaporation in mother liquor 900m 3 / h, the supernatant of ammonia distillation waste liquid is 90m 3 / h, temperature 72°C, graying water (at present, the graying water is the secondary reuse water sent by the evaporation process) 200 m 3 / h, temperature 55℃, flushing water 20 m 3 / h, the temperature is 55°C, and the concentration of milk of lime digested by the lime machine reaches 165tt (the special unit for the soda ash industry---titer, which is 1 / 20 of the equivalent concentration).

Embodiment 2

[0043] Evaporation in mother liquor 800m 3 Under the condition of 1 / h, the supernatant of ammonia distillation waste liquid is 80m 3 / h, temperature 72°C, secondary reuse water 155 m 3 / h, temperature 55℃, flushing water 20 m 3 / h, the temperature is 55°C, and the concentration of the milk of lime digested by the lime machine reaches 167tt (the special unit for the soda ash industry---titer, which is 1 / 20 of the equivalent concentration).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com