Automatic sorting method for fed cloth rolls

A cloth and cylinder-separating technology, applied in sorting, conveyor control devices, conveyors, etc., can solve problems such as low work efficiency, high labor costs, and easy fatigue, and achieve convenient operation, low production cost, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing:

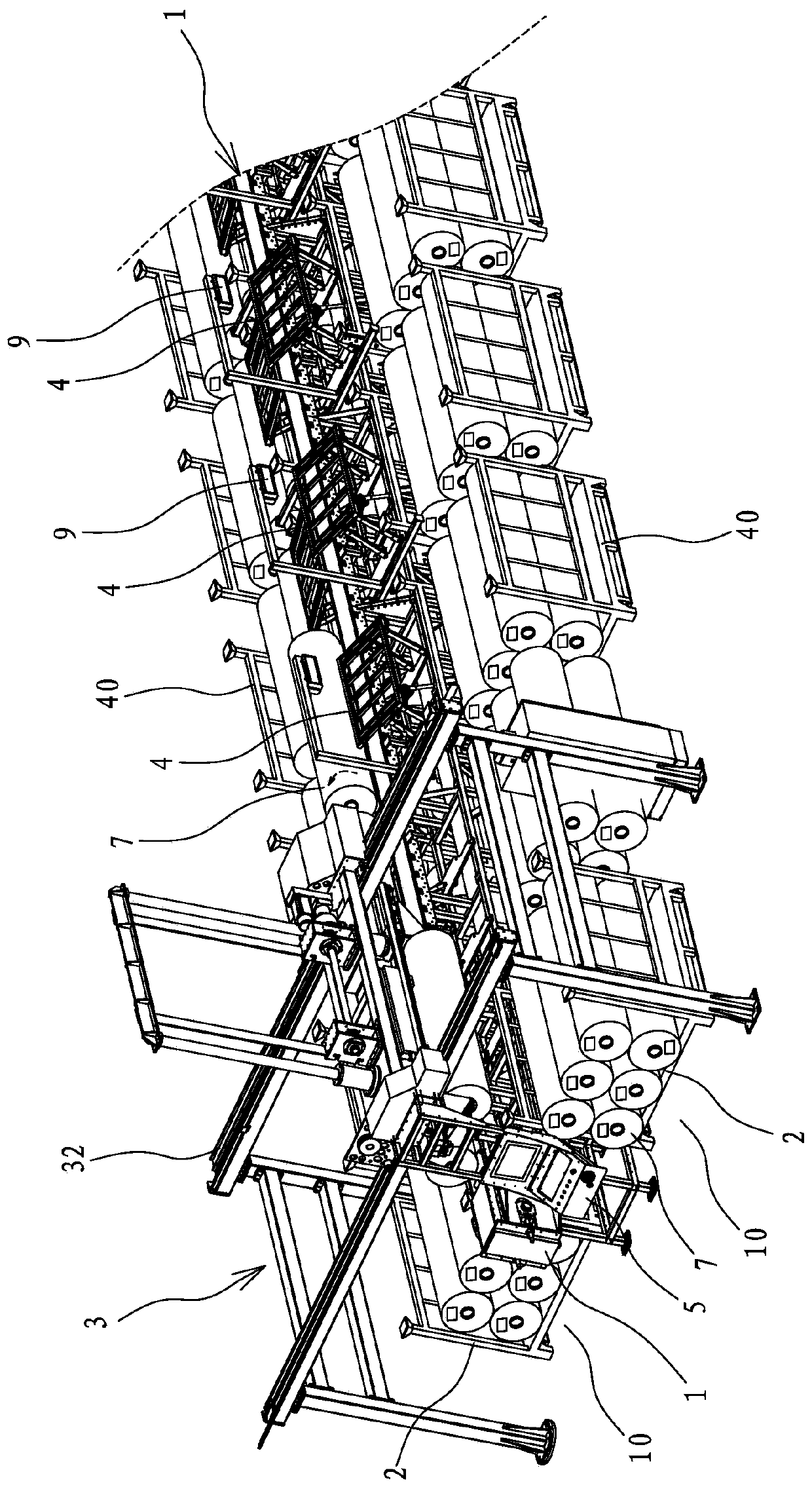

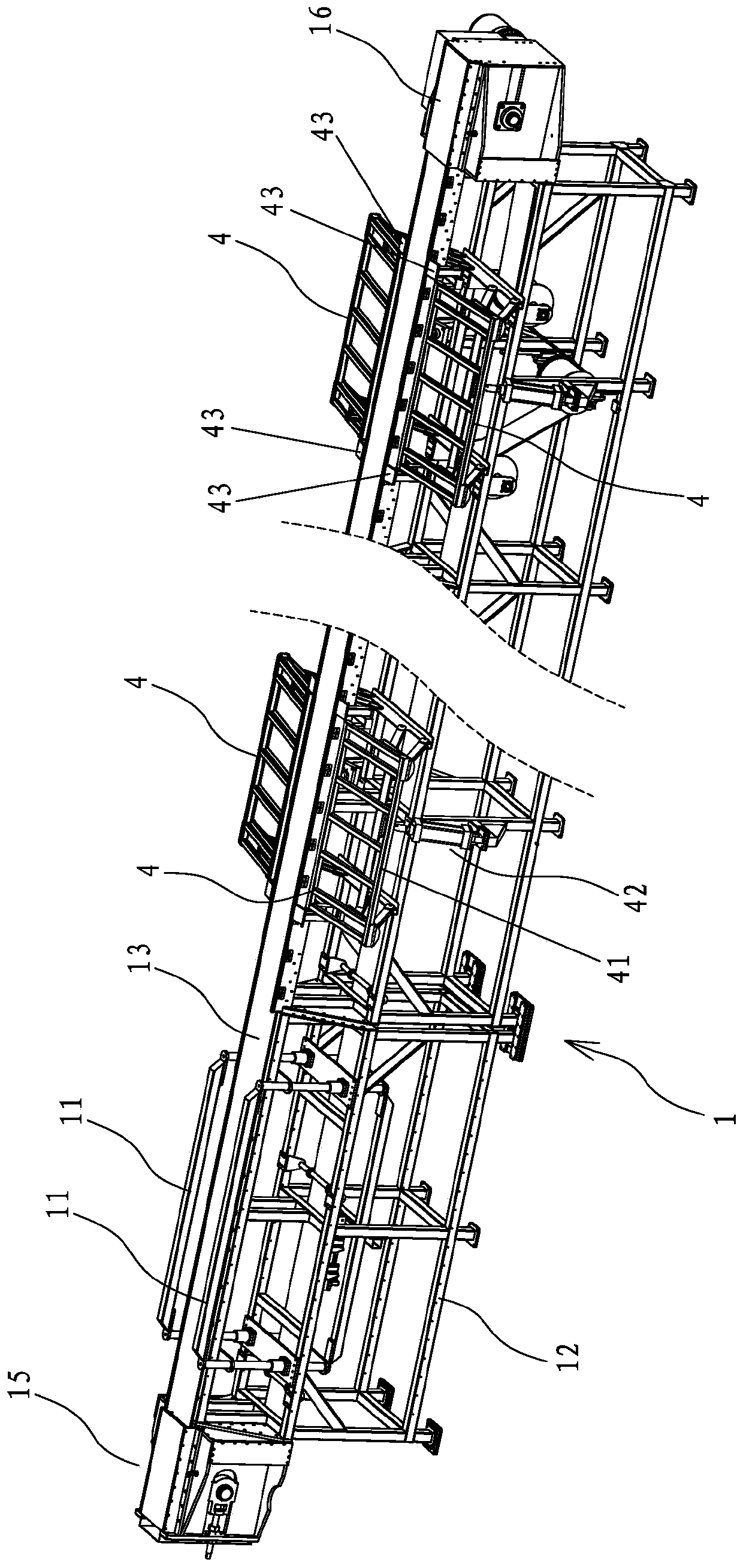

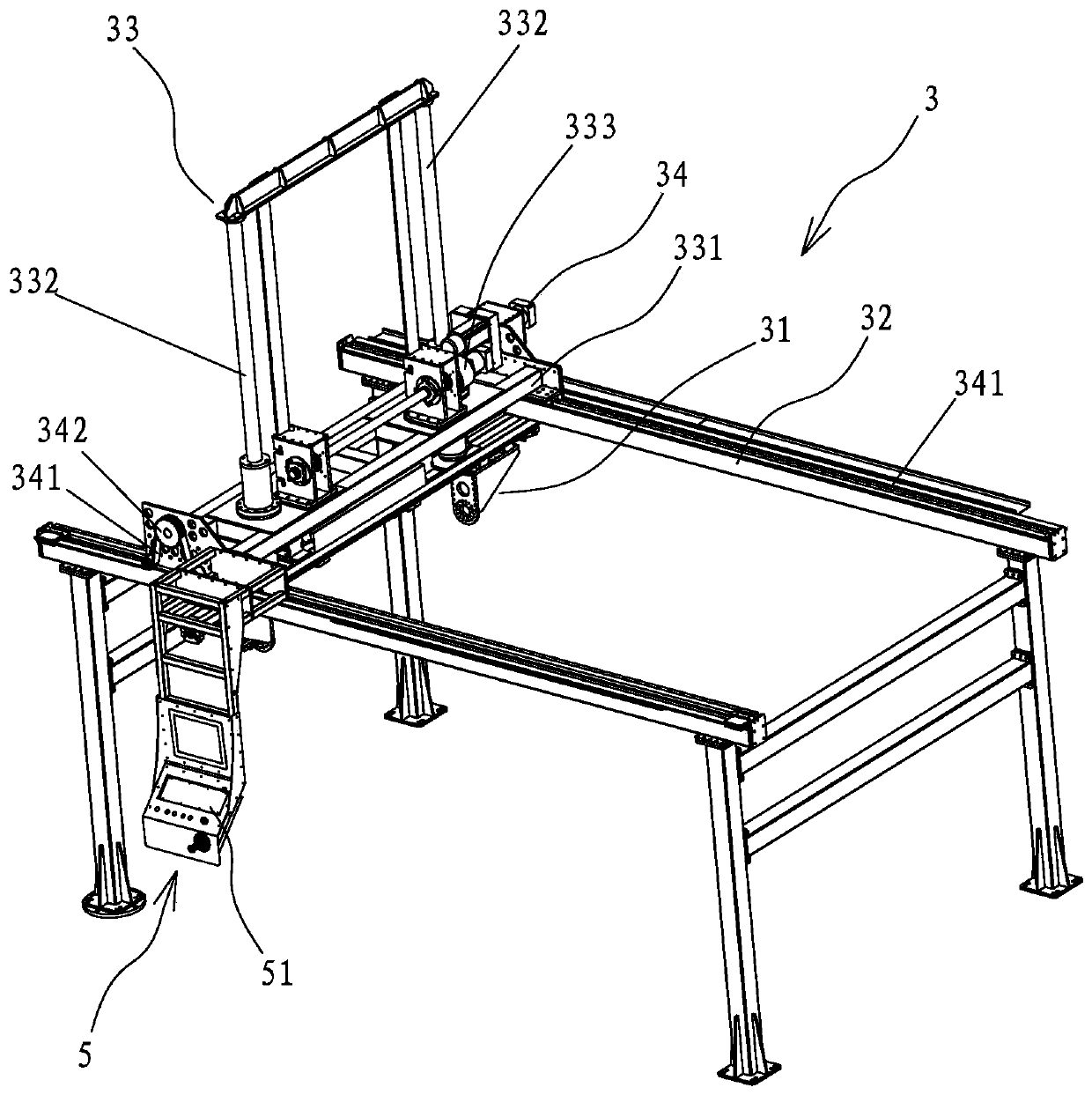

[0040] like Figure 1 to Figure 8 The shown one is used for the automatic cylinder division of incoming cloth, including a beat-running assembly line 1 that can move forward according to a certain stroke each time and is used to transport rolls of cloth 7. Preferably, the assembly line 1 is a belt The assembly line can move according to a certain beat, and each beat moves forward with the same stroke, that is, it moves forward for a stroke and then pauses for a period of time before continuing the movement of the next stroke. One end of the assembly line 1 is equipped with a material rack 2 The cloth 7 on the top is clamped and placed on the retrieving device 3 on the assembly line 1. The side of the assembly line 1 is provided with a plurality of unloading mechanisms 4 along the moving direction of the assembly line 1. The automatic cylinder line body also includes a set o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com