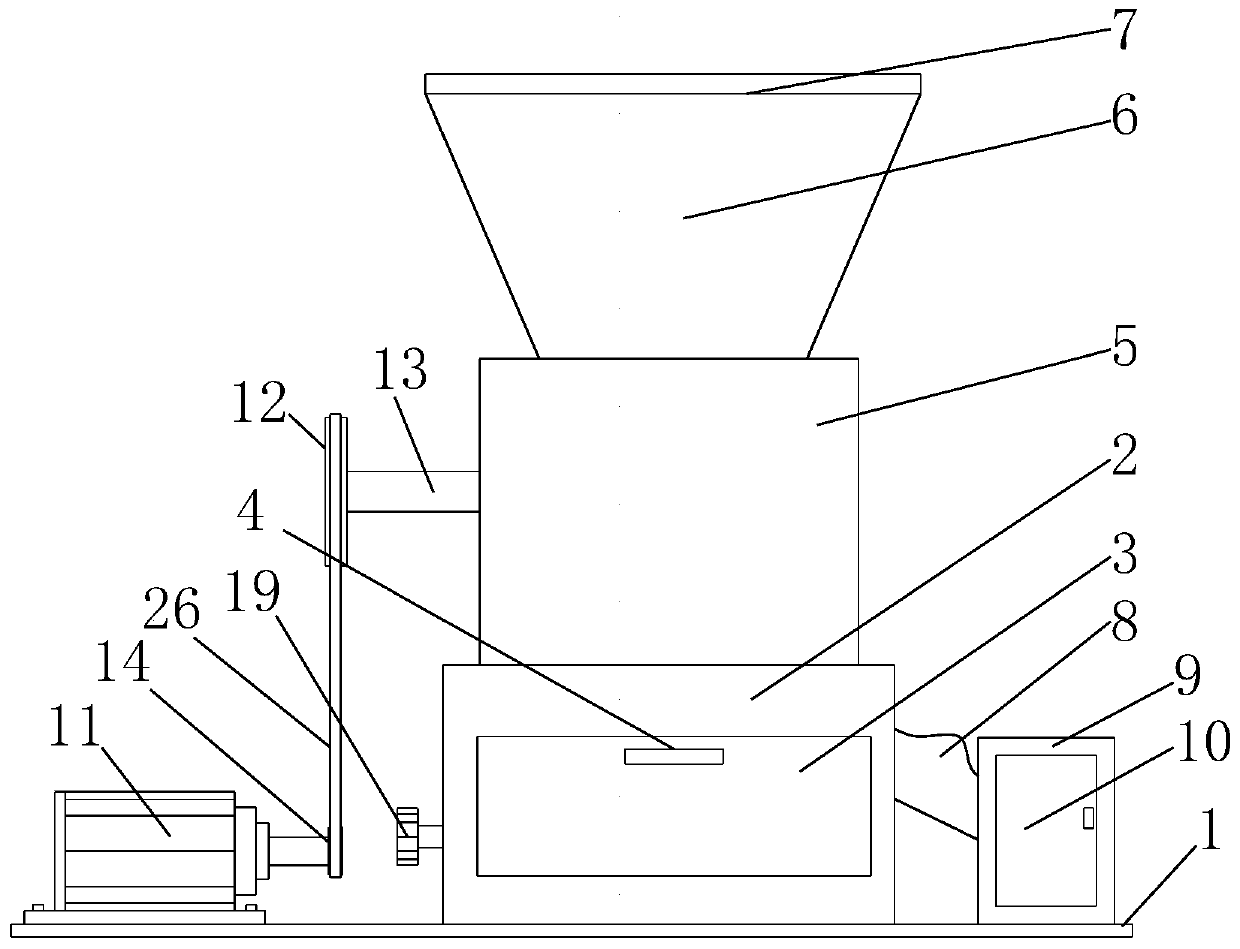

Traditional Chinese medicine superfine-grinding device for extracting effective components of herba epimedii

A technology of ultra-fine pulverization and traditional Chinese medicine, which is applied in medical preparations containing active ingredients, plant/algae/fungus/moss components, solid separation, etc. Time-saving, easy-to-use, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

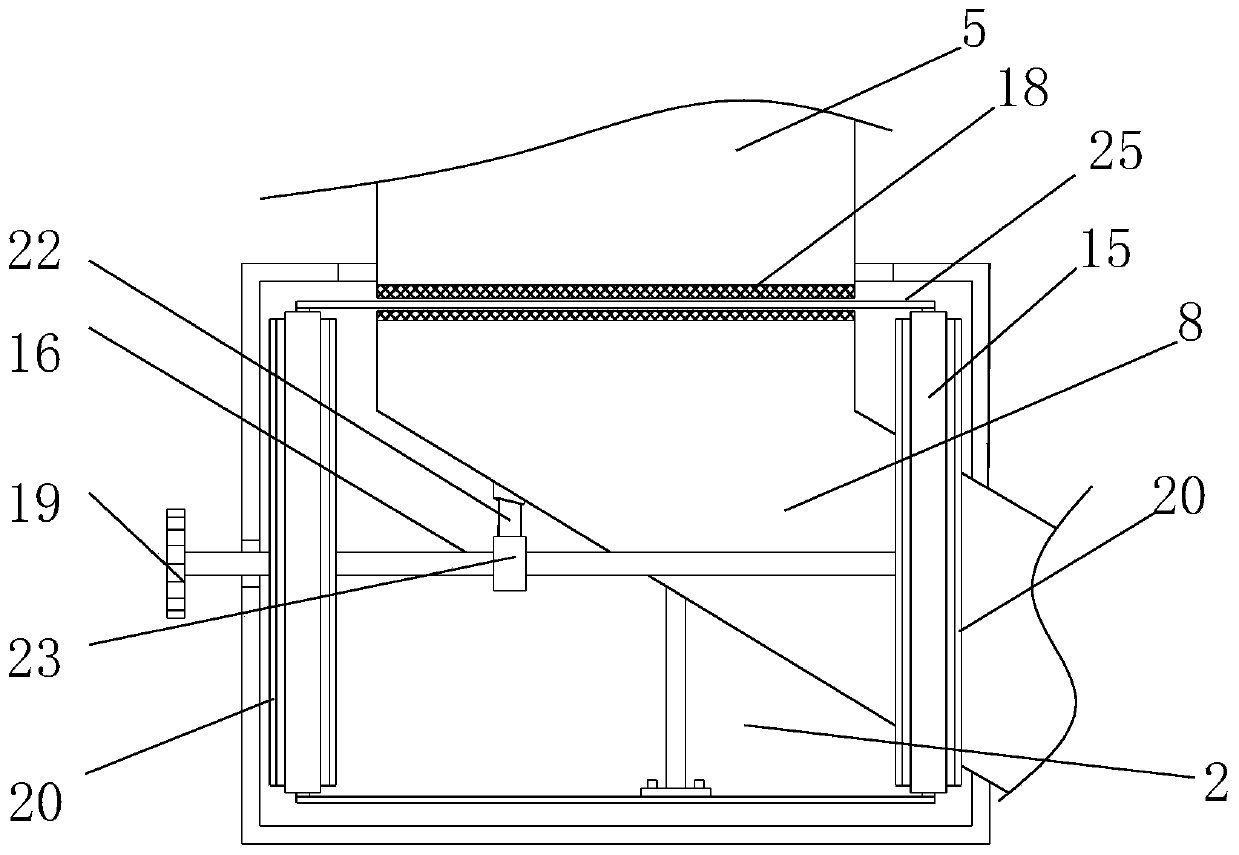

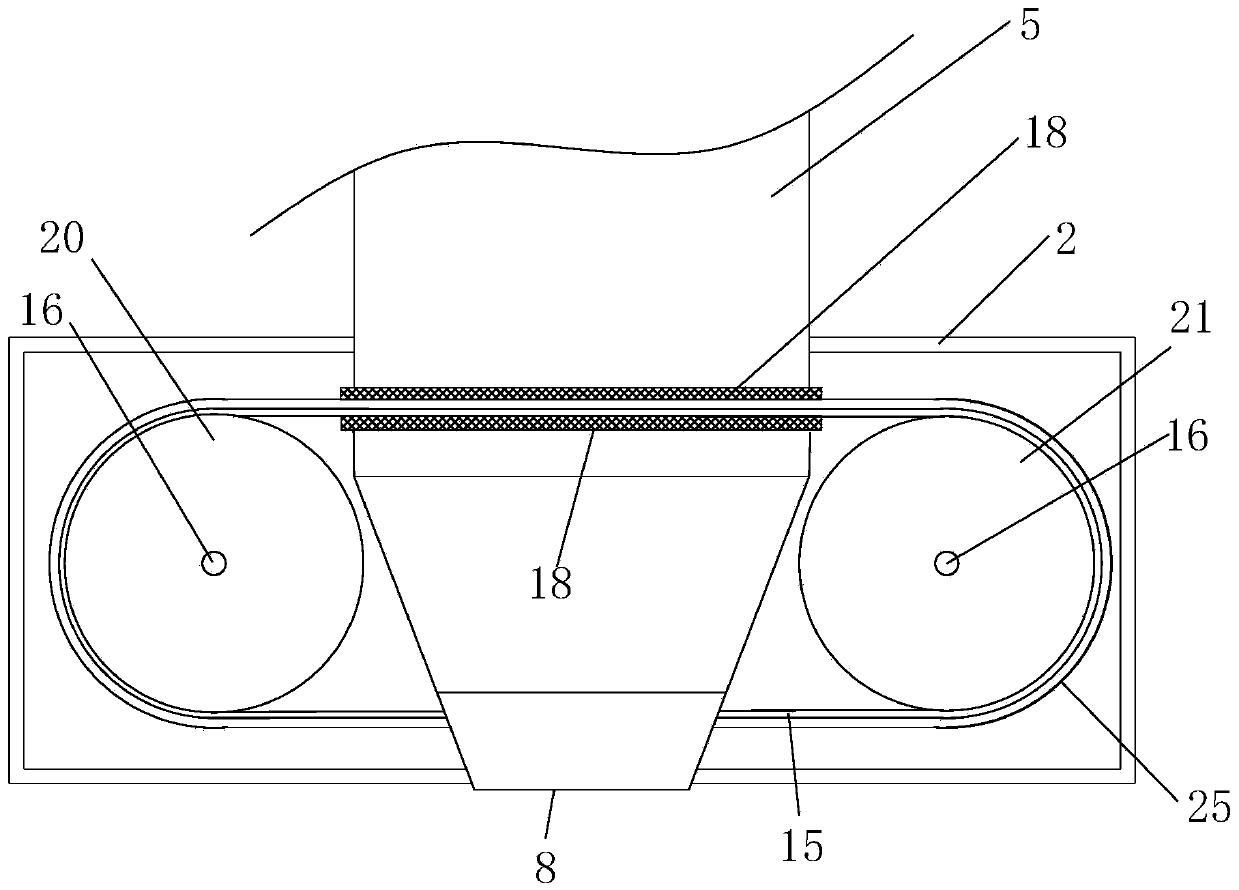

Method used

Image

Examples

Embodiment 1

[0039] Take by weighing the same batch of dried raw material Berberidaceae Epimedium, Epimedium leaf powder 3kg and stem powder 7kg after being pulverized by the ultrafine pulverizing device of the present invention, and the fineness is to cross 500 mesh sieve and 1000 mesh sieve respectively; Then soak with 50kg of ethanol, soaking in low temperature and high pressure and high temperature vacuum environment alternately; then soak in ethanol, soak in low temperature and high pressure and high temperature vacuum environment alternately; low temperature and high pressure refers to 1.2 atmospheres and 28 ℃; high temperature and low pressure refers to 0.5 atmospheric pressure and 4°C; the alternating frequency is once an hour, and the total soaking time is 6 hours each time;

[0040] Then pressurize and filter under 1.2 atmospheric pressure to obtain the filtrate, and the filtered solid phase is repeatedly soaked with 30 kg of ethanol and then pressure-filtered once under the same ...

Embodiment 2

[0042] Take by weighing the same batch of dry raw material Berberidaceae plant Epimedium, Epimedium leaf powder 3.6kg and stem powder 6.4kg after being pulverized by the ultrafine pulverizing device of the present invention, fineness is to cross 1000 mesh sieves and 2000 mesh respectively Sieve; then soak with 60kg of ethanol, soaking in low temperature high pressure and high temperature vacuum environment alternately; then soak in ethanol, soak in low temperature high pressure and high temperature vacuum environment alternately; low temperature high pressure refers to 1.2 atmospheres and 25 °C; high temperature and low pressure refers to The temperature is 0.5 atmosphere and 4°C; the alternating frequency is once every 2 hours, and the total soaking time is 8 hours each time;

[0043] Then pressurize and filter under 1.5 atmospheres to obtain the filtrate, and the filtered solid phase is repeatedly soaked with 50 kg of ethanol and then pressurized and filtered once under the s...

Embodiment 3

[0045] Take by weighing the same batch of dry raw material Berberidaceae plant Epimedium, Epimedium leaf powder 3kg and stem powder 7kg after being pulverized by the ultrafine pulverizing device of the present invention, the fineness is to cross 2000 mesh sieve and 5000 mesh sieve respectively; Then soak in 70kg of ethanol, soaking in low temperature, high pressure and high temperature vacuum environment alternately; then soak in ethanol, soak in low temperature, high pressure and high temperature vacuum environment alternately; low temperature and high pressure refers to 1.2 atmospheres and 28 ℃; high temperature and low pressure refers to 0.5 atmospheric pressure and 4°C; the alternating frequency is once an hour, and the total soaking time is 8 hours each time;

[0046] Then pressurize and filter under 1.2 atmospheres to obtain the filtrate, and the filtered solid phase is repeatedly soaked with 30 kg of ethanol and then pressurized and filtered once under the same condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com