Method for preparing coated medical burning adhesion-prevention type gauze bandage, as well as product and application of coated medical burning adhesion-prevention type gauze bandage

An anti-adhesion and gauze technology, applied in bandages, pharmaceutical formulations, textiles and papermaking, etc., can solve the problems of using non-specific protein burn dressings, reducing blood compatibility, affecting thrombus formation, etc., and achieve good bone growth-promoting performance, Effect of improving mechanical properties and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

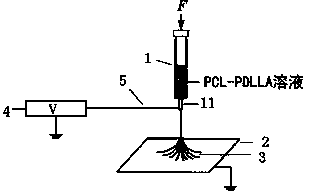

[0037] A film-coated medical burn antibacterial and anti-adhesion gauze bandage. The main structure is an ordinary veil bandage as a mechanical support layer. The bandage veil fibers are activated by surface treatment and coated with an adhesive. The surface of the material is constructed of polycaprolactone-polylactide copolymer (PCL-PDLLA polymer) hydrophobic fiber layer to avoid direct contact between the original gauze cotton fiber and the skin, and the plasma liquid components gushed out of the wound are absorbed by the cotton fiber through the fine and interlaced holes , the blood cells and protein components are blocked by the fiber layer and will not stick to the spinning layer. The schematic diagram of preparing the composite hydrophobic film layer gauze is as follows figure 1 Shown, prepared as follows:

[0038] Mix 0.2g of PCL-PDLLA with 2g of hexafluoroisopropanol, ultrasonicate for 30 minutes, and magnetically stir overnight to obtain a homogeneous solution of PCL...

Embodiment 2

[0041]A film-covered medical burn antibacterial anti-adhesion type gauze bandage is prepared according to the following steps:

[0042] Mix 0.2g of PCL-PDLLA and 2g of hexafluoroisopropanol at a mass ratio of 0.1:1, ultrasonicate for 30 minutes, and magnetically stir overnight to obtain a uniform solution of PCL-PDLLA / hexafluoroisopropanol with a mass concentration of 9%. Add 0.5% (HAp:PCL-PDLLA mass ratio) of HAp and continue to sonicate for 30 minutes; stir at room temperature for 12 hours to obtain a PCL-PDLLA / Hap / hexafluoroisopropanol solution; fill the resulting solution into a 10 mL glass syringe Inside, the equipment and conditions of electrospinning are the same as in the examples, covering the gauze on the aluminum foil and laying it on the receiver; at the spinning voltage of 15 KV, the spinning receiving distance is 10 cm, the diameter of the needle is about 0.1 mm, and the solution flow rate Under the condition of 0.4 mL / h, the composite nanofiber membrane composit...

Embodiment 3

[0045] A film-covered medical burn antibacterial anti-adhesion type gauze bandage is prepared according to the following steps:

[0046] Mix 0.2g of PCL-PDLLA and 2g of hexafluoroisopropanol at a mass ratio of 0.1:1, ultrasonicate for 30 minutes, and magnetically stir overnight to obtain a uniform solution of PCL-PDLLA / hexafluoroisopropanol with a mass concentration of 9%. Add 1% (HAp:PCL-PDLLA mass ratio) of HAp, and continue to sonicate for 30 minutes; stir at room temperature for 6~12h to obtain a PCL-PDLLA / Hap / hexafluoroisopropanol solution; put the resulting solution into a 10 mL In the glass syringe, cover the gauze on the aluminum foil and lay it on the receiver. The electrospinning process conditions are the same as in Example 1. The spinning voltage is 15KV, the spinning receiving distance is 10 cm, the needle diameter is about 0.1mm, and the solution flow rate Under the condition of 0.4 mL / h, the composite nanofiber film composite gauze was obtained by electrospinnin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com