A kind of production method of modified anti-scale and slow-release material

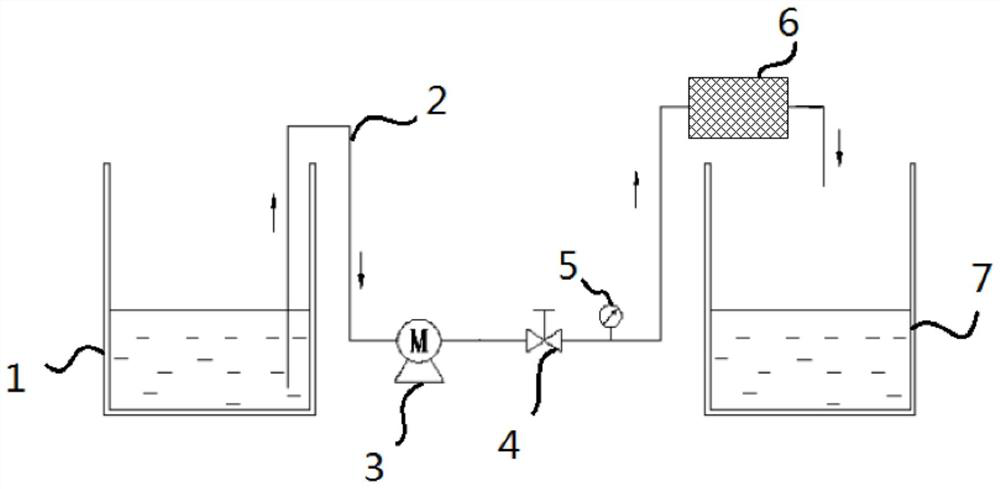

A production method and anti-scaling and anti-corrosion technology, applied in the field of materials, can solve the problems of uneven heating, explosion, corrosion and other problems of appliances, and achieve the effect of good controllability of release speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0166] Step 1. Obtain nano-hydroxyapatite (purchased from Shanghai McLean Biochemical Technology Co., Ltd.), the product information is as follows:

[0167] Table 1

[0168]

[0169] Step 2, drying the nano-hydroxyapatite at 120° C. for 3 hours in a vacuum drying oven to obtain the dried nano-hydroxyapatite. Disperse 100 g of dried nano-hydroxyapatite in 500 ml of N-ethylpyrrolidone (NEP).

[0170] Step 3, add 0.2g palmitoyl chloride (>96% (T)), 20g maleic anhydride (>99% (GC)) to the product of the previous step, and react at normal temperature and pressure for 5 hours.

[0171] In step 3, a representative chemical reaction formula of nano-hydroxyapatite and maleic anhydride is as follows (I). A representative chemical reaction formula of nano-hydroxyapatite and palmitoyl is as follows (II).

[0172]

[0173] In formula (I), maleic anhydride reacts with hydroxyapatite to obtain hydroxyapatite grafted with maleic acid on the surface. One carboxyl group of maleic acid...

Embodiment 2

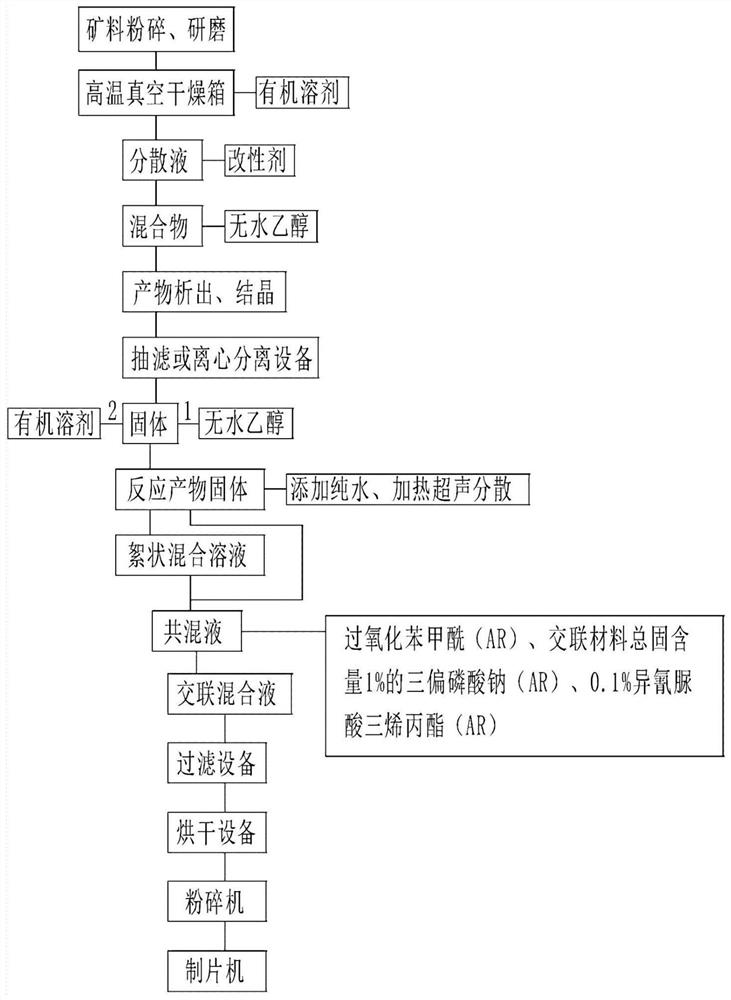

[0184] The steps of the production method of the modified scale and corrosion inhibiting material are as follows:

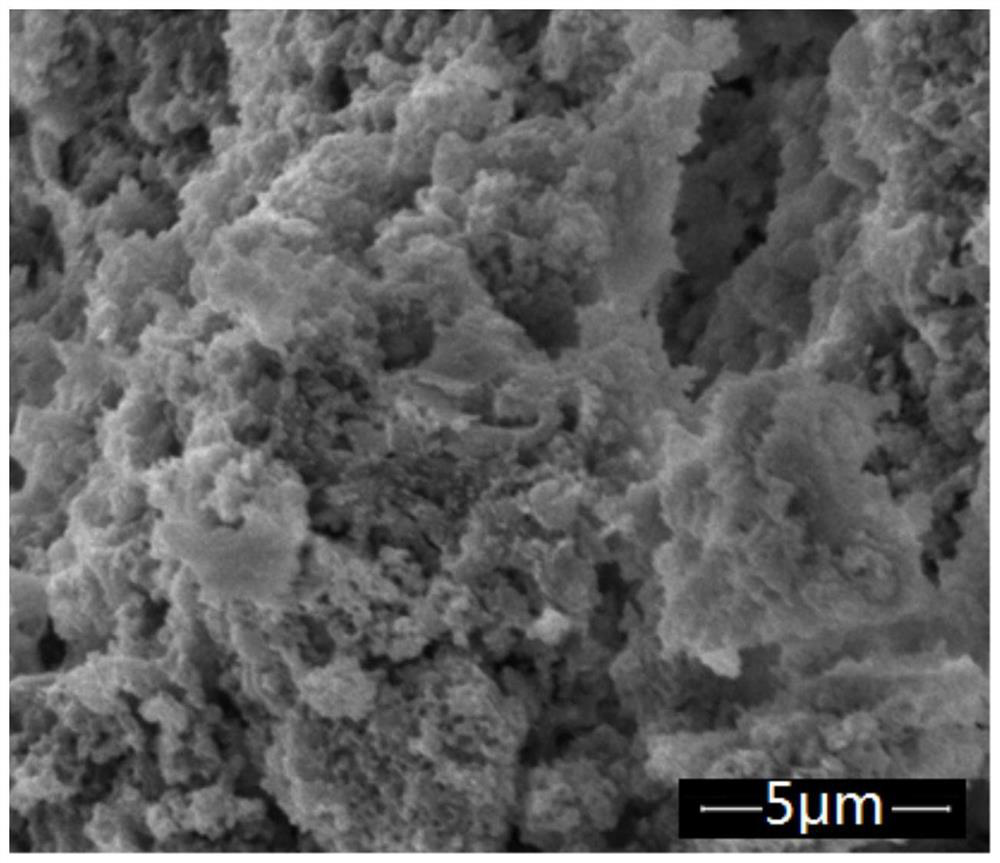

[0185] Step 1. Mineral crushing and grinding: In the clean workshop, high-purity calcite or hydroxyapatite or quartz stone or suitable inorganic materials (purity ≥ 99.9%) and other large specific surface area active materials are crushed to 320 Mesh, and then use the nano grinder to grind the pulverized material to 15-60nm or directly purchase the nano-scale material that meets the requirements;

[0186] Step 2. Mineral material dehydration and dispersion: the above-mentioned micropowder is dehydrated under reduced pressure at 120 degrees for 3 hours in a high-temperature vacuum drying oven, mixed with an appropriate amount of organic solvent, added to the reaction kettle and stirred repeatedly to make it evenly dispersed;

[0187] Step 3. Mixing reaction: add an appropriate amount of modifiers to the above dispersion liquid, such as octadecyltrichlorosilane, pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| solubility (mass) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com