Square billet hyperbolic-type submersed nozzle and manufacturing method thereof

A hyperbolic and production method technology, which is applied in the direction of manufacturing tools, casting molten material containers, metal processing equipment, etc., can solve the problem of reducing the proportion of the lower part of the nozzle, discontinuous inflow of liquid mold slag, and increasing the impact depth of the mold, etc. problems, to achieve the effect of improving the flow behavior of molten steel, avoiding the vacuum effect, and improving the internal and external quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

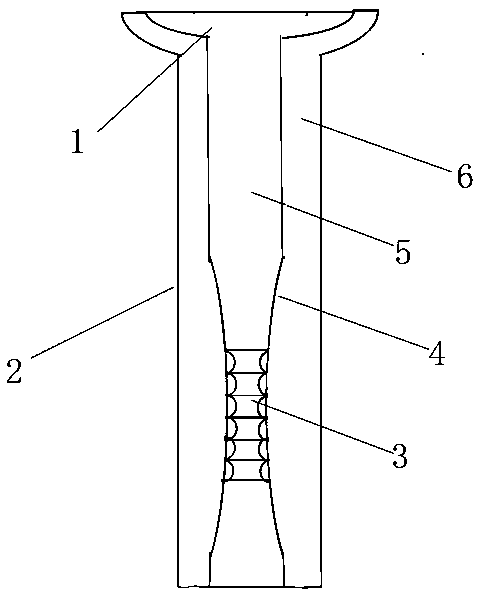

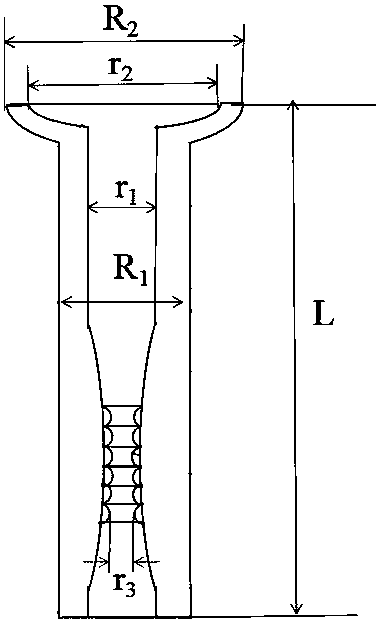

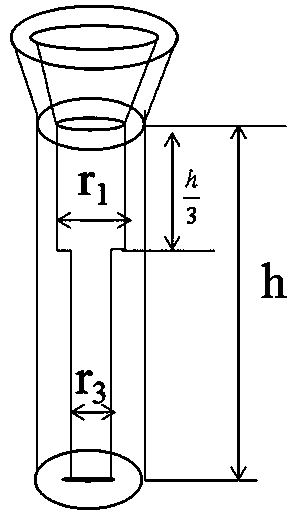

[0038] like figure 1As shown, a billet hyperbolic submerged nozzle includes a nozzle bowl 1, a nozzle cylinder 2 is provided at the bottom of the nozzle bowl 1, and the nozzle cylinder 2 includes a nozzle outer wall 6 and a nozzle arranged in the nozzle outer wall 6 The passage, the nozzle passage includes the nozzle straight passage 5 connected with the nozzle bowl 1 and the hyperbolic passage 4 communicated with the bottom of the nozzle straight passage 5, and the middle part of the hyperbolic passage 4 is provided with a deceleration ring 3, the nozzle bowl 1, the nozzle Cylinder 2 is processed in one piece.

[0039] A method for manufacturing a billet hyperbolic submerged nozzle, comprising the following steps: (Take specific data as an example for illustration)

[0040] Step 1): Design the total length L of the hyperbolic nozzle to be 56...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com