A graphene electric heating film loaded with cobalt-doped manganese oxide nanoparticles and its preparation method

A nanoparticle and electric heating film technology, which is applied in the direction of electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of film layer performance influence, uneven distribution of graphene and nanoparticles, etc., and achieve good dispersion and good durability. Chemically corrosive, not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

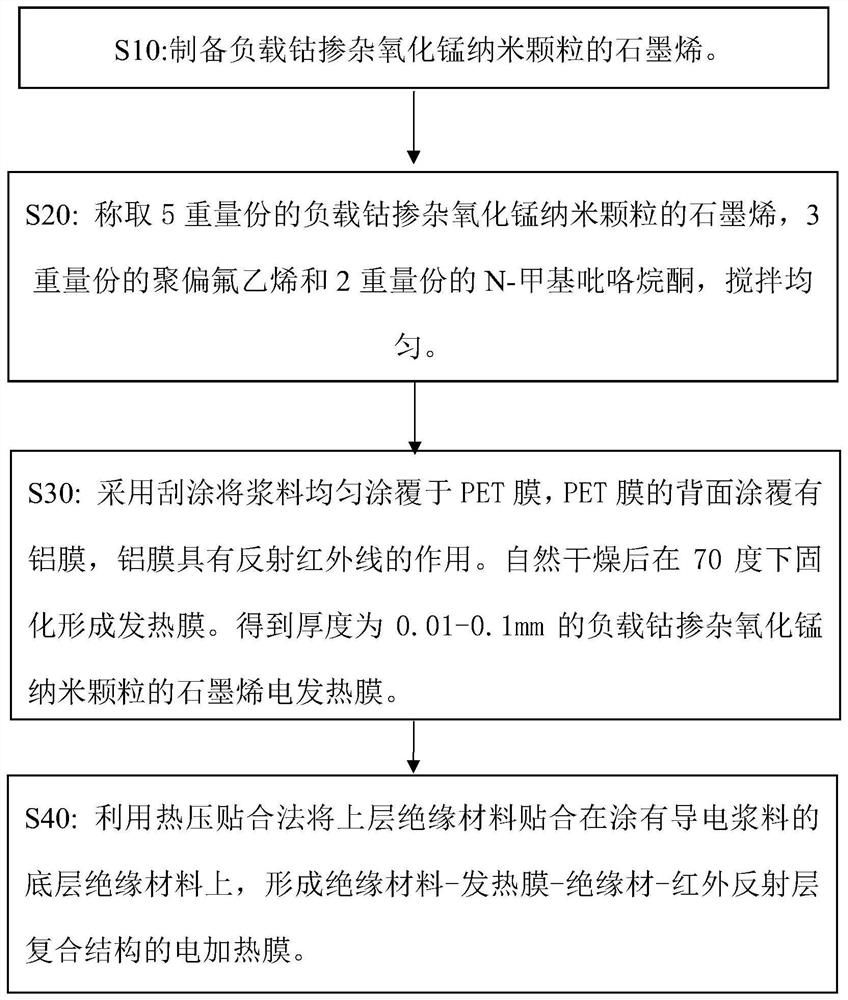

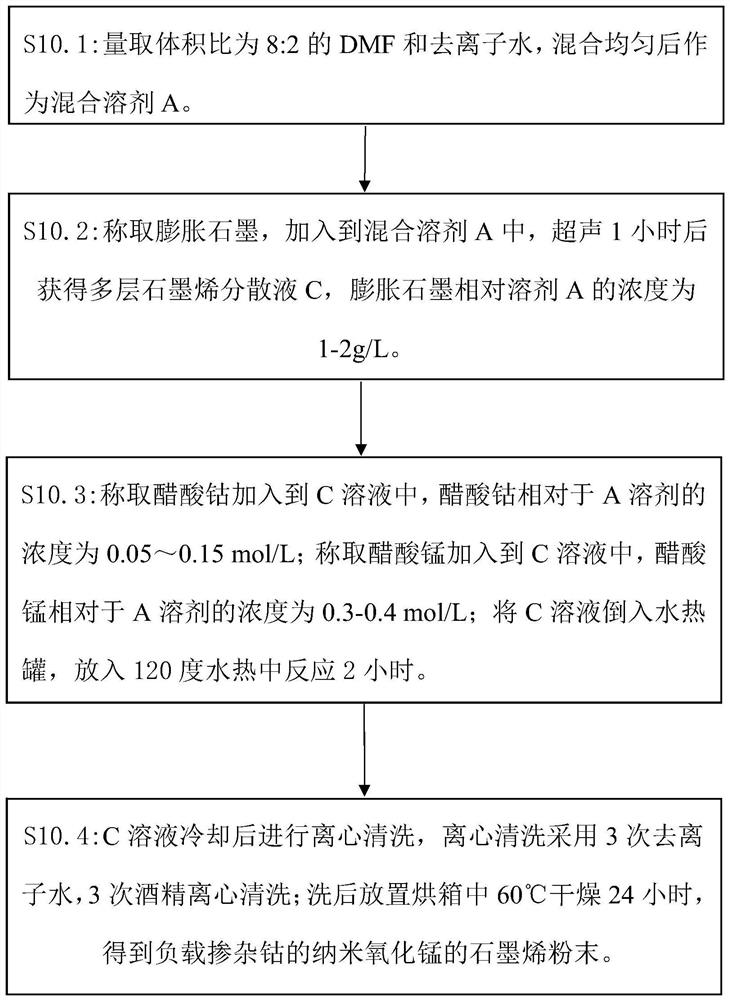

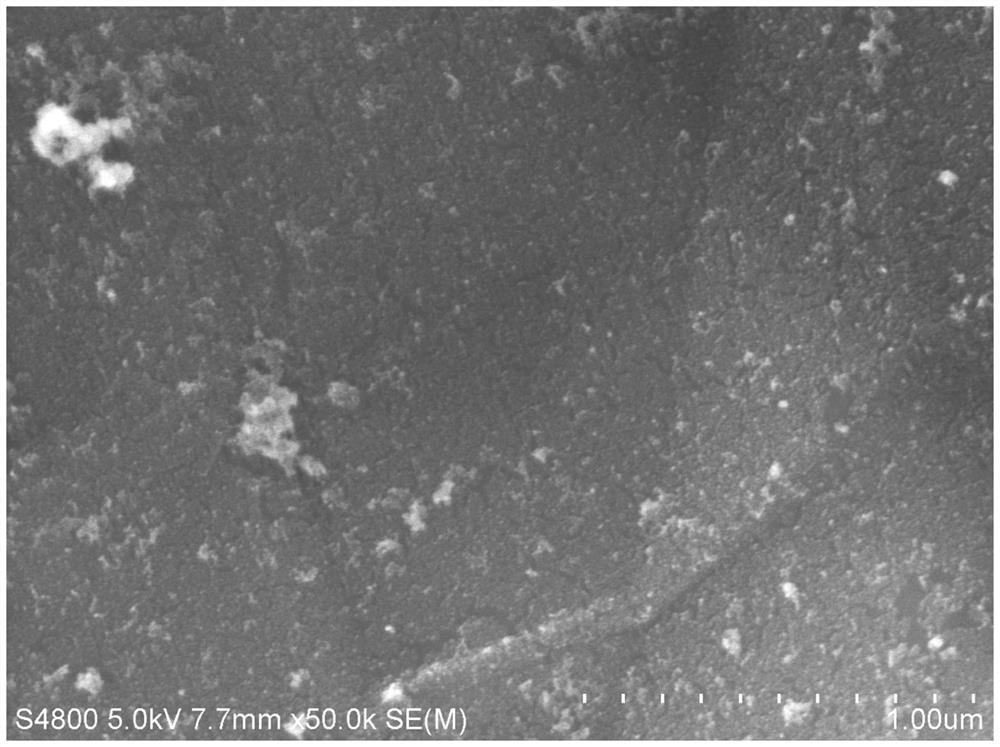

[0043] Preparation of graphene loaded with cobalt-doped manganese oxide nanoparticles. Put the graphene into the mixed solvent of DMF and water for ultrasonication for 1 hour, put in the weighed cobalt acetate and manganese acetate, stir at room temperature for 5 minutes, then pour the mixture into a water heating tank, and put it in a 120-degree oven for reaction After cooling for 2 hours, deionized water and alcohol were carried out three times for centrifugal cleaning, and then the sample was dried in a 60-degree oven, and manually ground and dispersed to obtain graphene powder loaded with cobalt-doped manganese oxide nanoparticles. Wherein the volume ratio of DMF and water is 7:3. The concentration of cobalt oxide in the solvent is 0.05mol / L, the concentration of manganese acetate in the solvent is 0.3mol / L, and the concentration of graphene in the solvent is 1g / L. figure 1The SEM image of the cobalt-doped manganese oxide nanoparticles supported on the surface of graphene...

Embodiment 2

[0049] Preparation of graphene loaded with cobalt-doped manganese oxide nanoparticles. Put the graphene into the mixed solvent of DMF and water for ultrasonication for 1 hour, put in the weighed cobalt acetate and manganese acetate, stir at room temperature for 5 minutes, then pour the mixture into a water heating tank, and put it in a 120-degree oven for reaction After cooling for 2 hours, deionized water and alcohol were carried out three times for centrifugal cleaning, and then the sample was dried in a 60-degree oven, and manually ground and dispersed to obtain graphene loaded with cobalt-doped manganese oxide nanoparticles. Wherein the volume ratio of DMF and water is 8:2. The concentration of cobalt oxide in the solvent is 0.1mol / L, the concentration of manganese acetate in the solvent is 0.35mol / L, and the concentration of graphene in the solvent is 1.5g / L.

[0050] Prepare the heat-generating film slurry. Weigh 5 parts by weight of graphene loaded with cobalt-doped m...

Embodiment 3

[0054] Preparation of graphene loaded with cobalt-doped manganese oxide nanoparticles. Put the graphene into the mixed solvent of DMF and water for ultrasonication for 1 hour, put in the weighed cobalt acetate and manganese acetate, stir at room temperature for 5 minutes, then pour the mixture into a water heating tank, and put it in a 120-degree oven for reaction After cooling for 2 hours, deionized water and alcohol were carried out three times for centrifugal cleaning, and then the sample was dried in a 60-degree oven, and manually ground and dispersed to obtain graphene loaded with cobalt-doped manganese oxide nanoparticles. Wherein the volume ratio of DMF and water is 9:1. The concentration of cobalt acetate in the solvent is 0.1mol / L, the concentration of manganese acetate in the solvent is 0.4mol / L, and the concentration of graphene in the solvent is 2g / L.

[0055] Prepare the heat-generating film slurry. Weigh 5 parts by weight of graphene loaded with cobalt-doped ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com