Battery pack heat dissipation device with centralized heat dissipation

A technology of heat dissipation device and battery pack, which is applied in the direction of batteries, secondary batteries, circuits, etc., which can solve the problems of general heat dissipation of batteries, failure of heat dissipation of batteries, and contact with battery electrodes, so as to avoid violent combustion or even explosion caused by thermal runaway , Improve the safety of use, and effectively dissipate heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention provides a battery pack cooling device for centralized heat dissipation. In order to make the purpose, technical solution and effect of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the protection scope of the present invention.

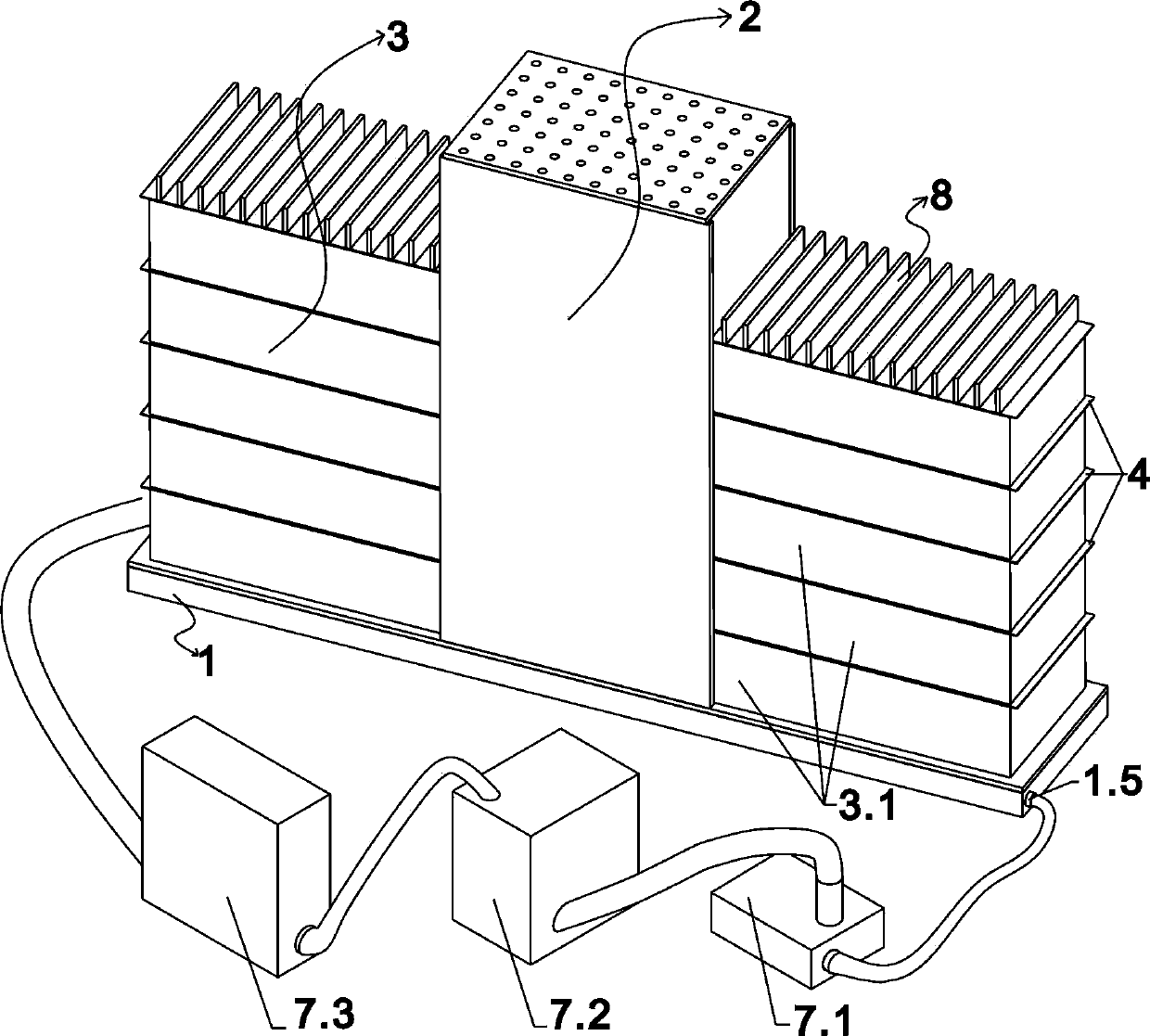

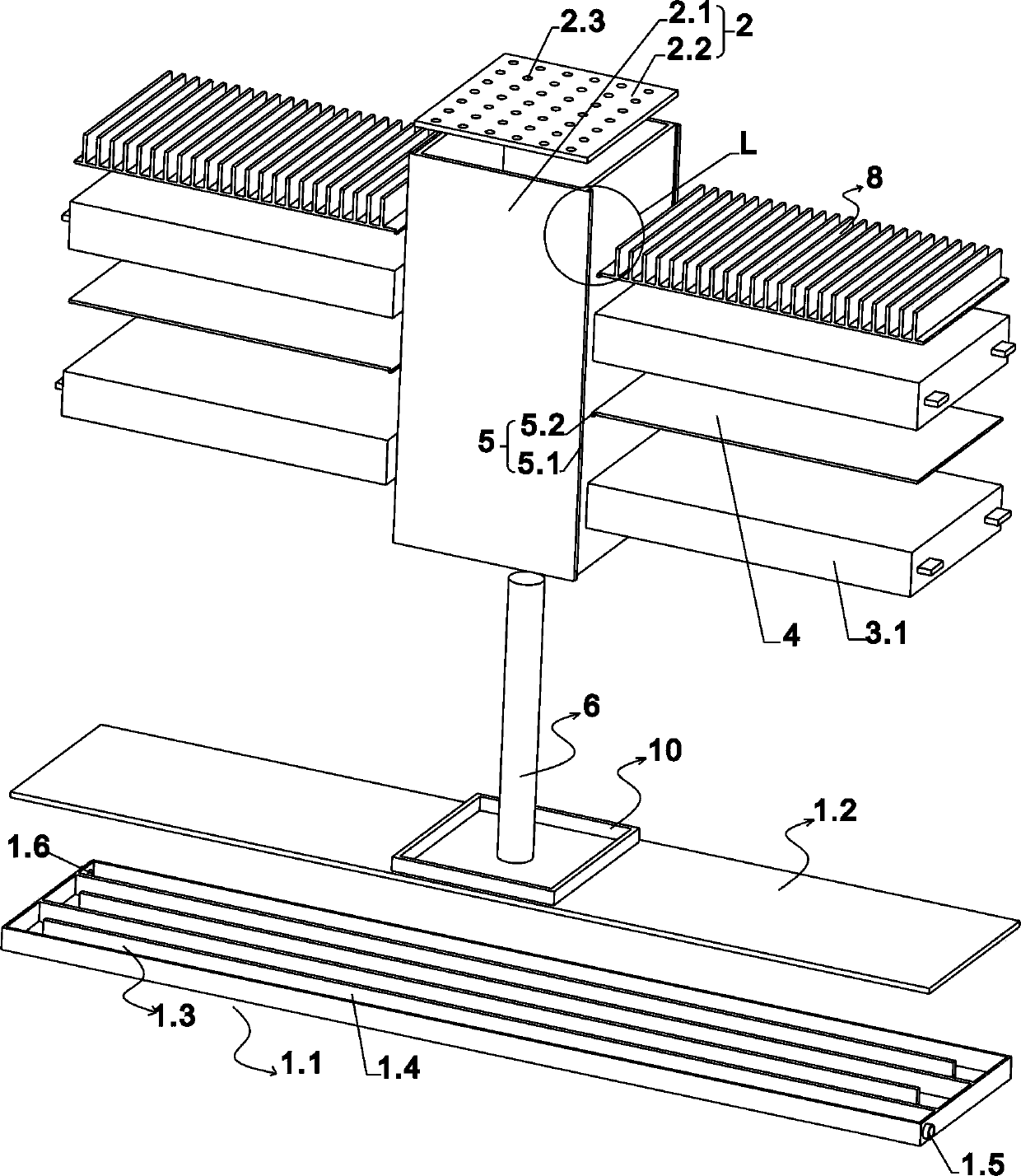

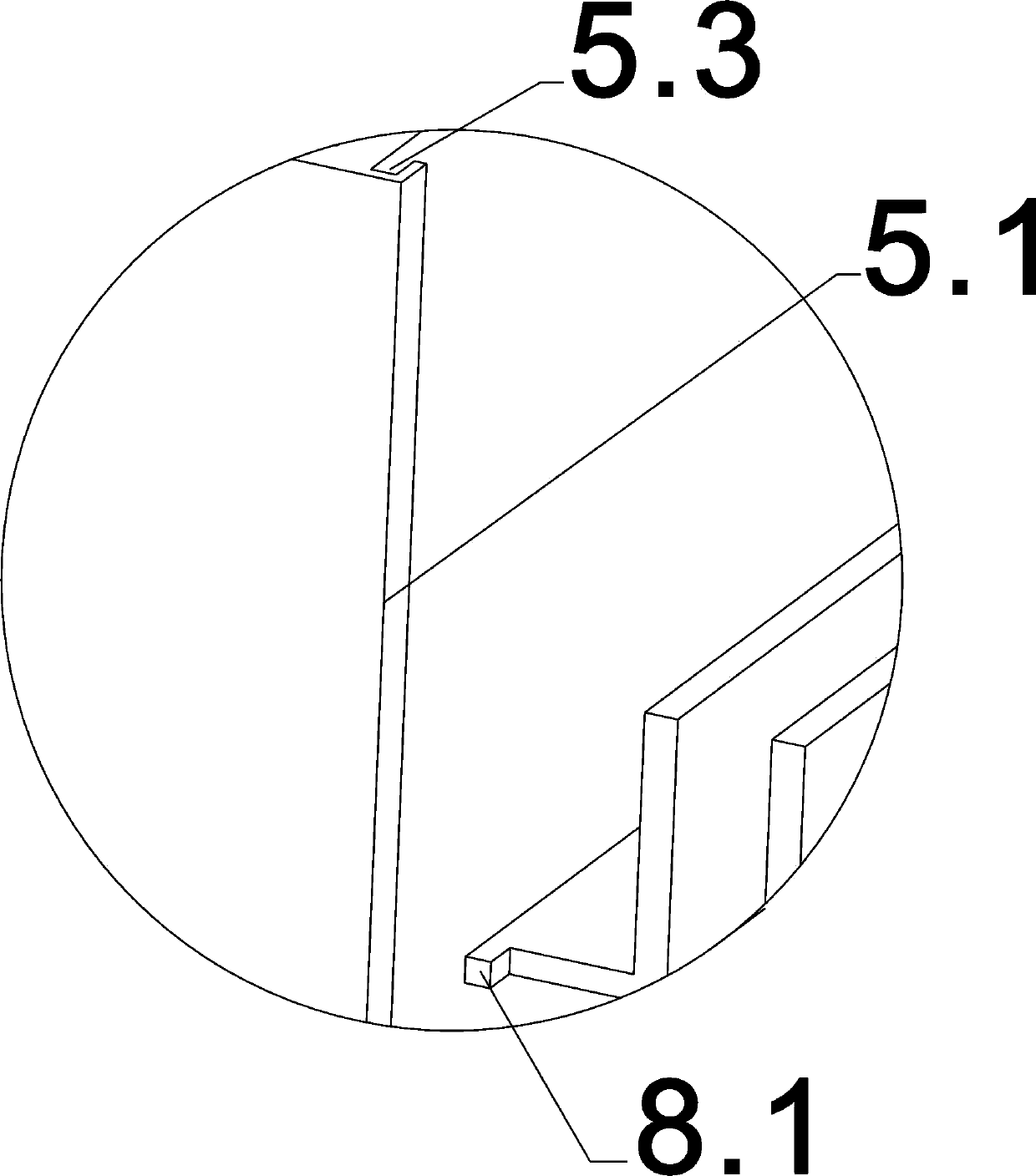

[0024] see Figure 1-Figure 2 , the present invention provides a battery pack cooling device for centralized heat dissipation, including a base 1, a cooling box 2 arranged on the upper end surface of the base, and several battery packs 3 (no more than 4). The inner cavity of variable material, each battery group corresponds to one side facing the heat dissipation box, the battery group 3 is formed by stacking a plurality of battery cells 3.1 in the vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com