Tail gas dehydrogenation device for fuel cell automobile

A fuel cell and vehicle exhaust technology, which is applied in battery/fuel cell control devices, fuel cells, electric vehicles, etc., can solve the problems of inconvenient installation and disassembly of devices, complicated adjustment and control, and large fluctuations in hydrogen concentration, so as to reduce potential impacts. and hazards, easy installation and disassembly, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

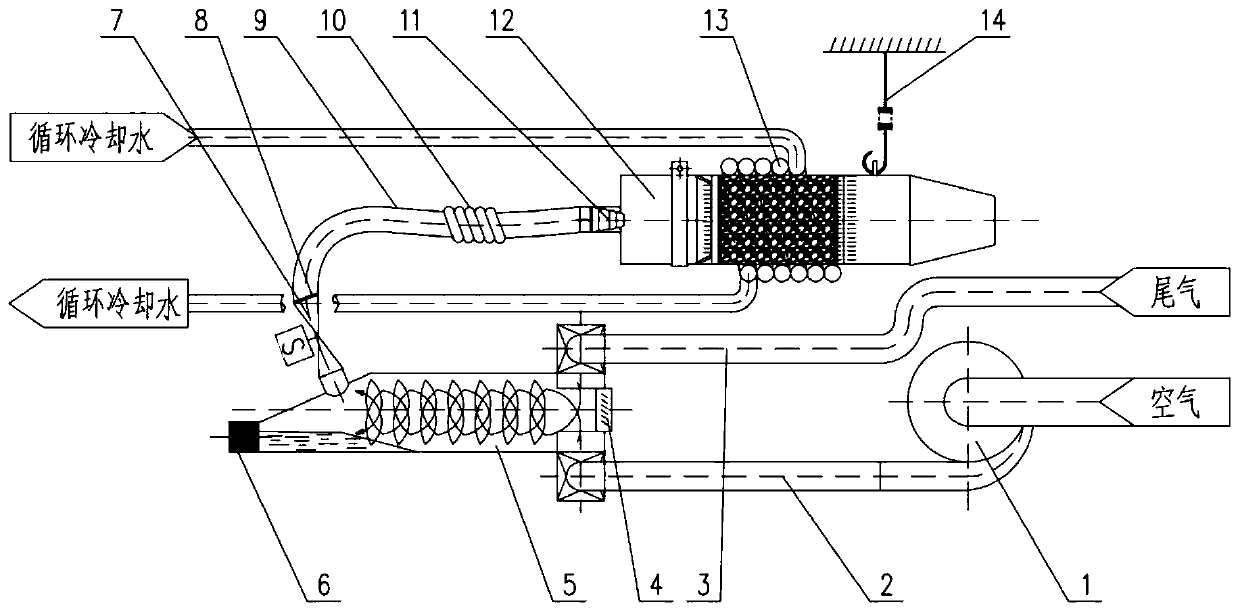

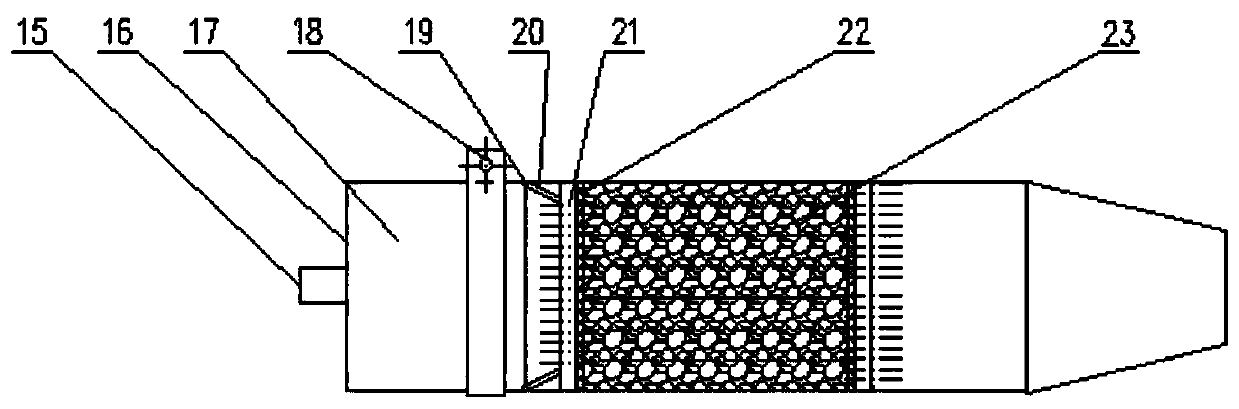

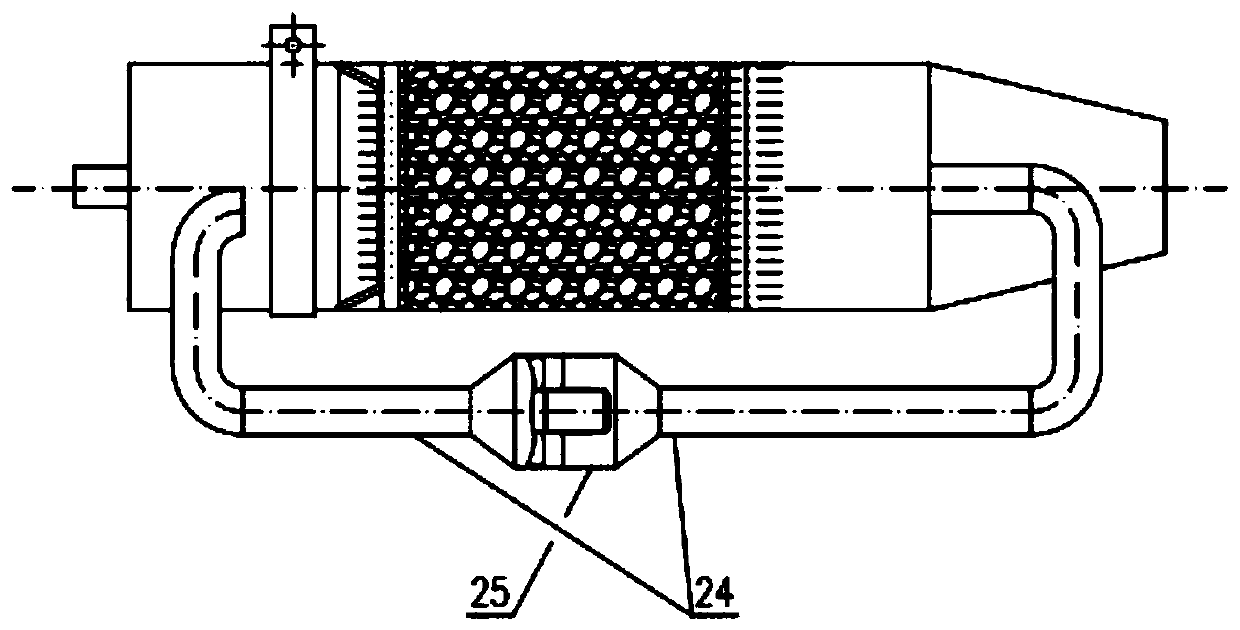

[0024] The overall structure of a fuel cell vehicle tail gas dehydrogenation device of the present invention is shown in figure 1 , including a cyclone separator 5, a burst disc 4, a solenoid valve 7, an air pipe 2, an intake fan 1, a hose 9, and a catalytic converter 12. The system includes exhaust gas collection, separation, buffering, air injection, and mixing. The catalytic converter 12 equipped with a catalyst is connected to the catalytic converter 12 with a soft connection quick joint 11 that is easy to install and disassemble, so as to realize exhaust gas collection, steam-water separation, injection of air dilution, and catalytic reaction, so that the hydrogen in the exhaust gas of the fuel cell vehicle can be safely discharged after generating water, and the system is integrated High strength, easy to disassemble.

[0025] The exhaust pipe 3 used to receive the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com