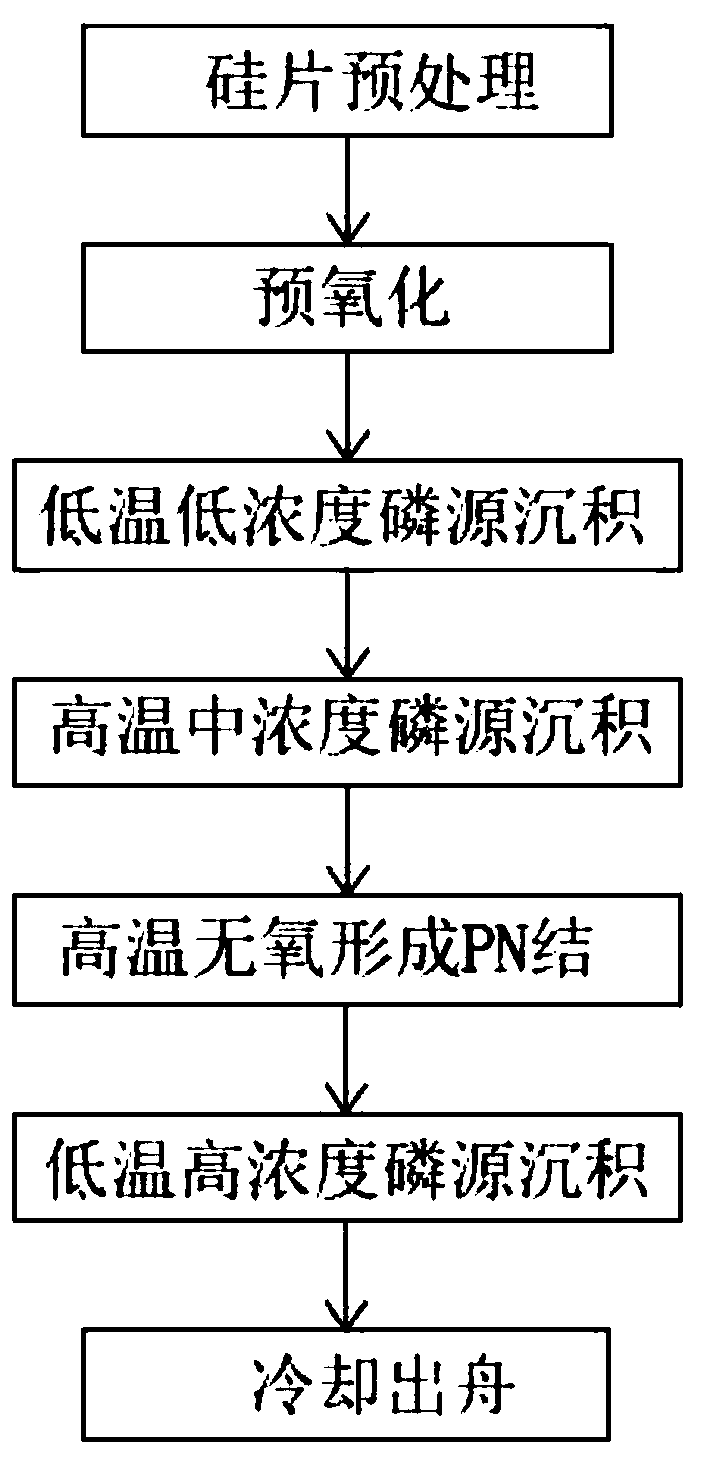

Regional layered deposition diffusion process

A layered deposition and diffusion process technology, applied in the direction of climate sustainability, sustainable manufacturing/processing, photovoltaic power generation, etc., can solve the problems of weak regional diffusion controllability, poor blue light response of batteries, and low minority carrier lifetime. Achieve excellent high minority carrier lifetime, reduce recombination, and reduce the concentration of impurity sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

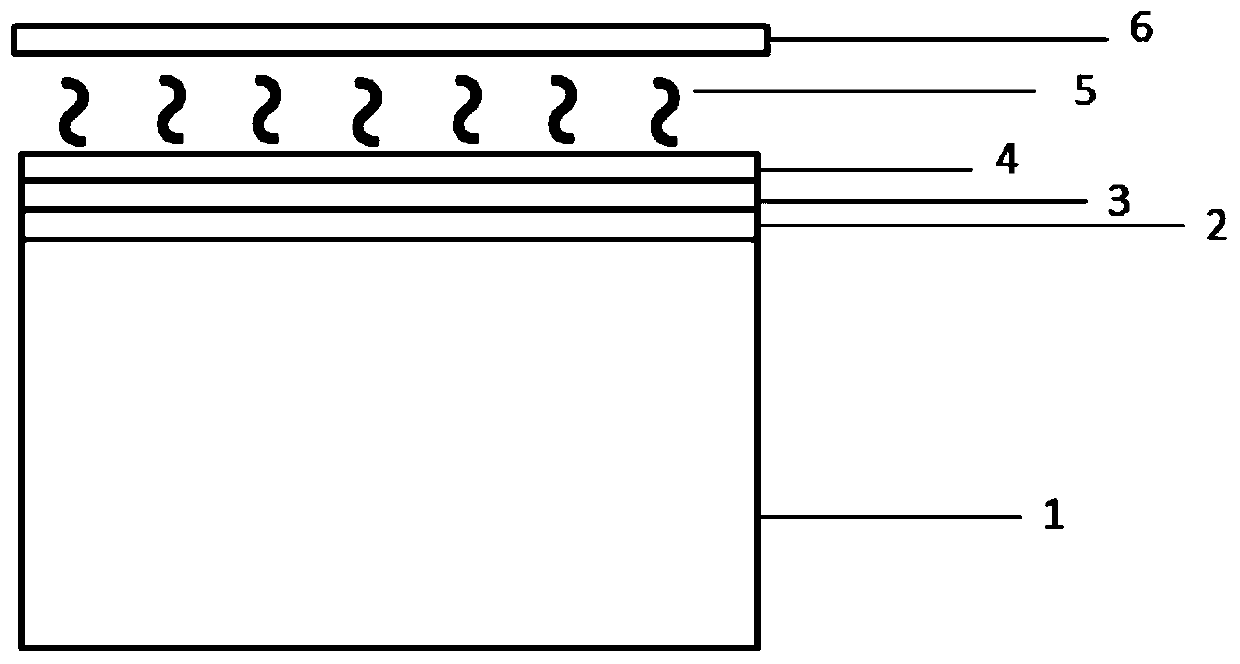

[0034] (1) if figure 1 and figure 2 As shown, silicon wafer pretreatment: clean and texture the P-type original silicon wafer 1, put it into a quartz boat, and push it into the furnace tube of the diffusion furnace;

[0035] (2) Pre-oxidation: raise the temperature of the diffusion furnace to 680°C, inject 3000 sccm of nitrogen and 3000 sccm of oxygen, control the pressure of the furnace tube at 50 mbar, and pre-oxidize the silicon wafer after texturing for 10 minutes to form SiO 2 Layer 2;

[0036] (3) Low temperature and low concentration POCl 3 Deposition: heat up the diffusion furnace to a temperature of 700°C, and inject POCl 3 300sccm, oxygen 700sccm, nitrogen 1000sccm, controlled furnace tube pressure 80mbar, low-temperature and low-concentration phosphorus source deposition on the pre-oxidized silicon wafer for 5min to form low-concentration POCl 3 deposition layer 3;

[0037] (4) Medium concentration POCl in temperature rise 3 Deposition: heat up the diffusion...

Embodiment 2

[0042] (1) if figure 1 and figure 2 As shown, silicon wafer pretreatment: clean and texture the P-type original silicon wafer 1, put it into a quartz boat, and push it into the furnace tube of the diffusion furnace;

[0043] (2) Pre-oxidation: raise the temperature of the diffusion furnace to 700°C, inject 4000 sccm of nitrogen and 4000 sccm of oxygen, control the pressure of the furnace tube to 100 mbar, and pre-oxidize the silicon wafer after texturing for 12 minutes to form SiO 2 Layer 2;

[0044] (3) Low temperature and low concentration POCl 3 Deposition: heat up the diffusion furnace to a temperature of 710°C, and feed POCl 3 250sccm, oxygen 750sccm, nitrogen 1100sccm, controlled furnace tube pressure 100mbar, low-temperature and low-concentration phosphorus source deposition on the pre-oxidized silicon wafer for 4min to form low-concentration POCl 3 deposition layer 3;

[0045] (4) Medium concentration POCl in temperature rise 3 Deposition: heat up the diffusion...

Embodiment 3

[0050] (1) if figure 1 and figure 2 As shown, silicon wafer pretreatment: clean and texture the P-type original silicon wafer 1, put it into a quartz boat, and push it into the furnace tube of the diffusion furnace;

[0051] (2) Pre-oxidation: raise the temperature of the diffusion furnace to 720°C, inject 5000 sccm of nitrogen and 5000 sccm of oxygen, control the pressure of the furnace tube at 150 mbar, and pre-oxidize the silicon wafer after texturing for 15 minutes to form SiO 2 Layer 2;

[0052] (3) Low temperature and low concentration POCl 3 Deposition: maintain the temperature of the diffusion furnace at 720°C, and feed POCl 3 200sccm, oxygen 800sccm, nitrogen 1200sccm, controlled furnace tube pressure 150mbar, low-temperature and low-concentration phosphorus source deposition on the pre-oxidized silicon wafer for 3min to form low-concentration POCl 3 deposition layer 3;

[0053] (4) Medium concentration POCl in temperature rise 3 Deposition: raise the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com