Bearing assembly clearance on-line measuring machine and clearance measuring method thereof

A bearing assembly, measuring machine technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as out-of-tolerance, inconsistent clearance, etc., to improve accuracy and consistency, avoid wear, and improve accuracy and consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing.

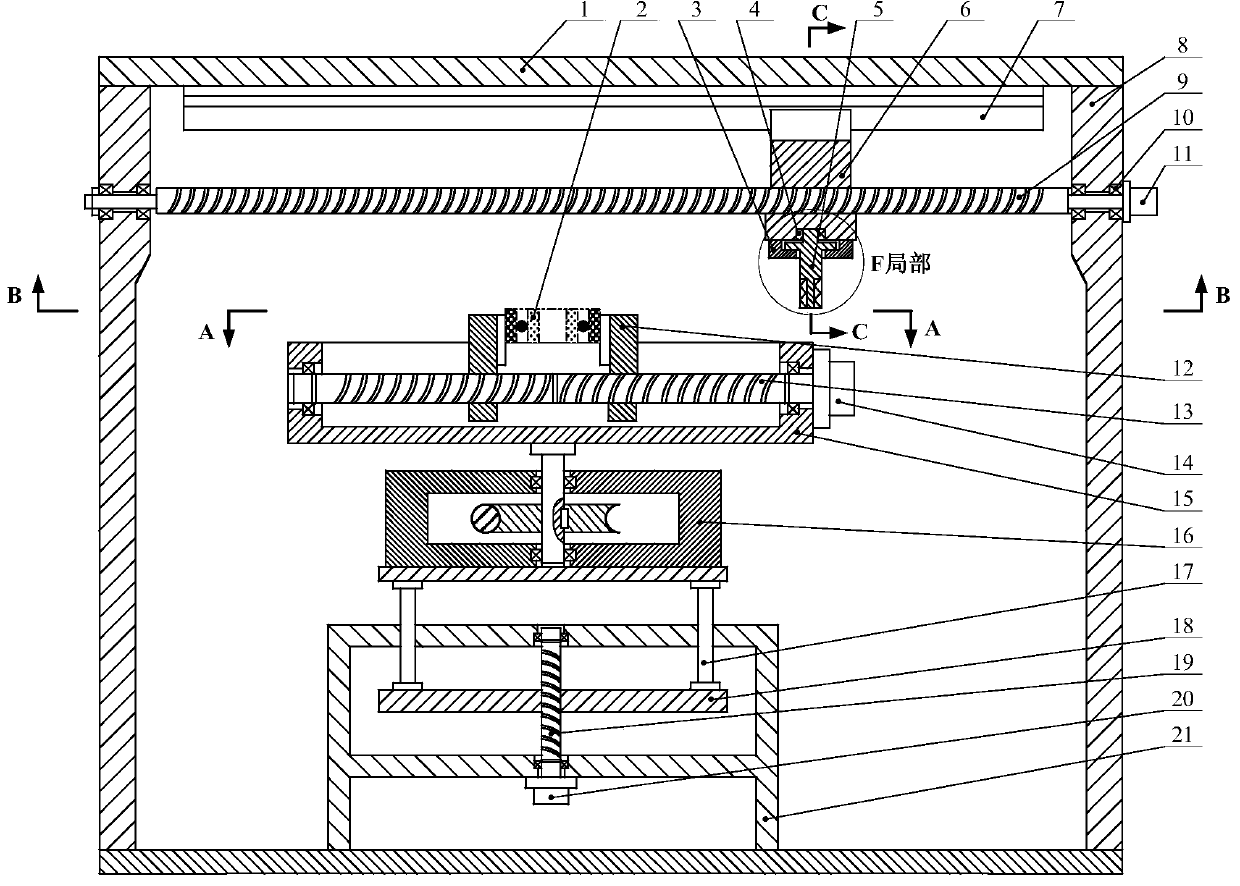

[0036] like figure 1 As shown, an online measuring machine for bearing assembly clearance includes a top plate 1, a body 8, a worktable lifting and rotating mechanism, a clamping workbench, a constant pressure measuring mechanism and a controller. The workbench lifting and rotating mechanism includes a lifting guide column 17, a lifting platform 18, a lifting drive assembly, a rotating drive assembly 16 and a lifting frame 21. Lifting frame 21 is fixed on the fuselage 8 . The four corners of lifting platform 18 are all fixed with vertically arranged lifting guide posts 17 . Four guide sleeves fixed on the fuselage 8 and four lifting guide posts 17 constitute sliding pairs respectively. The lifting drive assembly includes a lifting nut, a lifting screw mandrel 19 and a lifting motor 20 . The vertically arranged lifting screw mandrel 19 is supported on the lifting frame 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com