Aqueous polymer coating composition for automobiles

A water-based polymer and composition technology, used in anti-corrosion coatings, polyester coatings, coatings, etc., can solve the problem of long leveling time and pre-baking time, long and short wavelengths of paint coating film, reducing production takt, etc. problems, to achieve the effect of reducing pre-baking time, short pre-baking time, and improving leveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

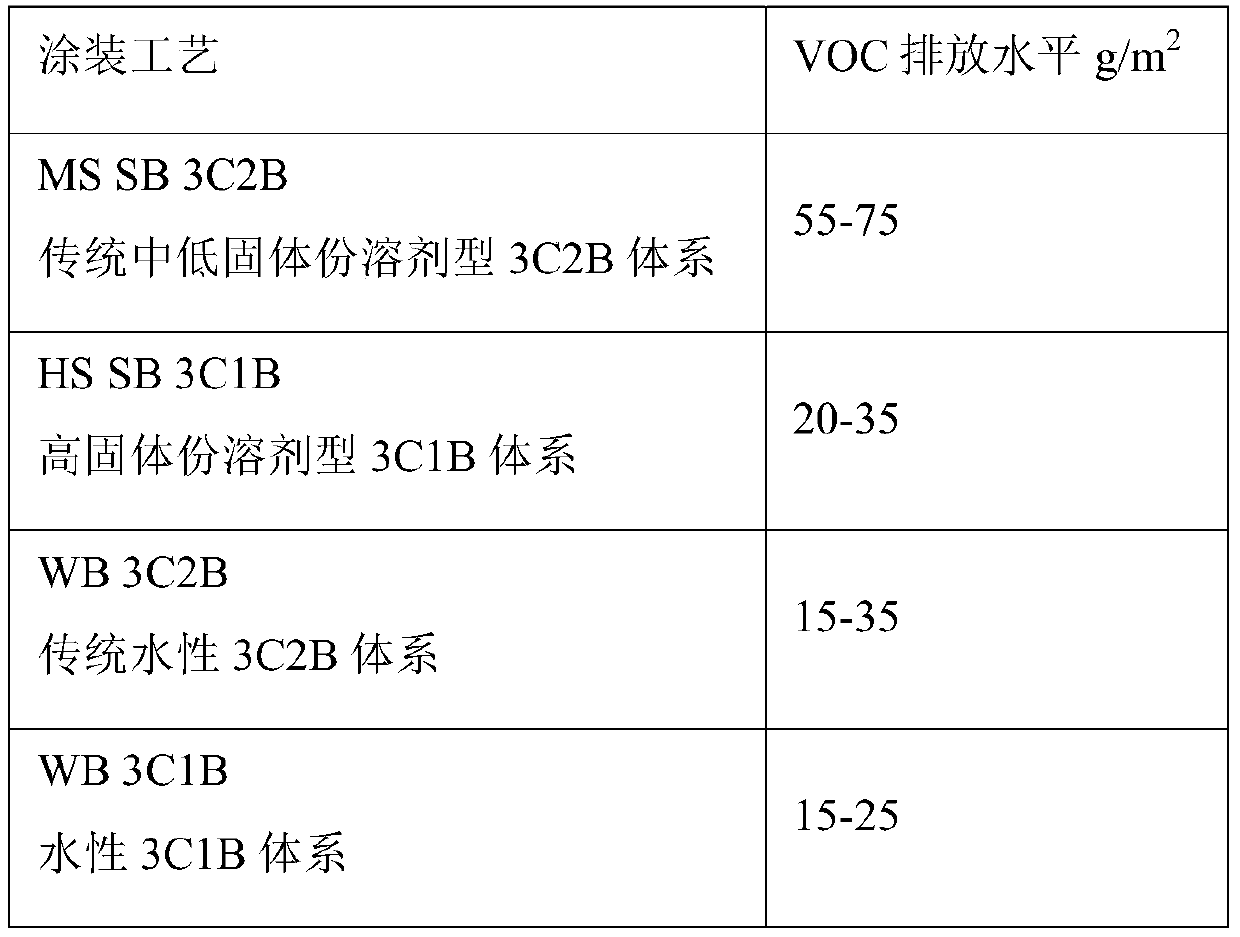

[0047] The selected raw materials and consumption of the water-based polymer coating composition for automobiles are as shown in Table 2:

[0048] Table 2

[0049]

[0050] The preparation method of the water-based polymer coating composition for automobiles in this embodiment includes the following steps: adding the components VIACRYL VSC 6800w / 47WA, YG-SD842, diethylene glycol butyl ether, pure water, RHODOLINE 3100, and FS-204 DPM in sequence In a suitable container, stir for 30 minutes, then slowly add CR-97 and BYK-011, stir for 30 minutes, use a sand mill to grind the above mixed materials to a fineness of less than 5um, filter, calculate the yield, according to the yield Slowly add Luwipal069, CYMEL 285, TEGO Wet 280, DYNOL 980, DMEA 10% solution and stir for 30 minutes to obtain the automotive water-based polymer coating composition described in Example 1.

[0051] The automobile water-based polymer coating composition prepared in Example 1 was used to coat the fil...

Embodiment 2

[0067] The automobile water-based polymer coating composition of the present embodiment comprises the component of following parts by weight: 50 parts of VIACRYLVSC 6276w / 44WA, 10 parts of VIACRYL VSC 6800w / 47WA, 4 parts of Luwipal 069 (full methyl etherification), 1 part of CYMEL285 ( Mixed etherification), 1 part of DMEA 10% solution, 5 parts of CR-97, 20 parts of diethylene glycol butyl ether, 5 parts of water, 2 parts of SOLSPERSE27000, 0.1 part of TEGO Wet 280, 0.1 part of DYNOL 980, 1 part of FS- 204 DPM, 0.8 parts BYK-011.

[0068] The preparation method is the same as in Example 1.

Embodiment 3

[0070] The automobile water-based polymer coating composition of the present embodiment comprises the component of following parts by weight: 10 parts of VIACRYLVSC 6276w / 44WA, 50 parts of VIACRYL VSC 6800w / 47WA, 8 parts of Luwipal 069 (full methyl etherification), 2 parts of CYMEL285 ( Mixed etherification), 5 parts of DMEA 10% solution, 15 parts of CR-97, 5 parts of diethylene glycol butyl ether, 1 part of water, 3 parts of SOLSPERSE27000, 0.2 parts of TEGO Wet 280, 0.2 parts of DYNOL 980, 0.3 parts of FS- 204 DPM, 0.3 parts BYK-011.

[0071] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com