Primer-topcoat type waterborne epoxy ester coating for tower crane standard parts, and preparation method thereof

A standard component, epoxy ester technology, applied in the direction of coating, etc., can solve the problems of easy yellowing, poor water resistance of paint, poor color and gloss retention of resin film, etc., to achieve excellent gloss retention and weather resistance The effect of good performance and good decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

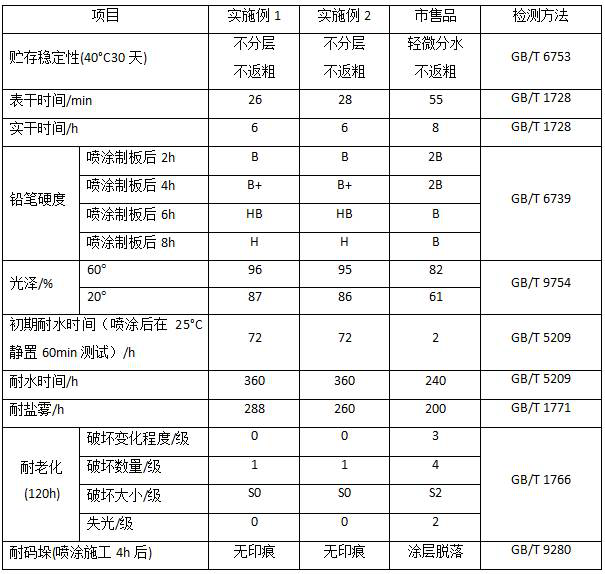

Examples

Embodiment 1

[0046] The ratio of each component of the gray water-based paint in the embodiment of the bottom-surface-integrated water-based epoxy ester coating for the standard part of the tower crane of the present invention: 150g of vinyl modified epoxy ester resin, 4g of pH regulator, 161.8g of deionized water, propylene glycol benzene Ether (produced by Dow, USA) 24g, drier ADDITOL VXW 6206 (produced by allnex, USA) 3.6g, dispersant TEGO Dispers760W (produced by Evonik, Germany) 24g, defoamer TEGO Foamex 860 (produced by Evonik, Germany) 1.2g , anti-sagging agent Bentone EW (produced by Deqian Hemings) 4.2g, sericite (325 mesh, produced by Chuzhou Gree) 6.6g, barium sulfate (produced by Hunan Ruishi) 82.8g, wollastonite powder (NYCO Minerals 23.2g, strontium phosphosilicate Halox SW111 (produced by ICL) 25.4g, R706 titanium dioxide (produced by Chemours) 68.3g, carbon black MA100 (produced by Mitsubishi, Japan) 4.2g, lemon yellow PY81 (H10G, produced by Clariant ) 4.6g, iron red (prod...

Embodiment 2

[0053] Example of water-based epoxy ester coating with bottom surface integrated type for tower crane standard parts of the present invention Apple green water-based coating The proportion of each component: vinyl modified epoxy ester resin 150g, pH regulator 4g, deionized water 161.8g, propylene glycol phenyl ether (Dow, USA) 24g, drier Octa-Soligen 421 aqua (Bayer, Germany) 3.6g, dispersant BYK-191 (Bick, Germany) 24g, defoamer TEGO Foamex 860 (Evonik, Germany) 1.2 g. Anti-sagging agent Bentone EW (produced by Deqian Hemings) 4.2g, sericite (325 mesh, produced by Chuzhou Gree) 6.2g, nano-high gloss barium (produced by Hunan Ruishi) 83.2g, wollastonite powder (NYCO Minerals) 23.6g, strontium phosphosilicate Halox SW111 (ICL) 25.0g, R706 titanium dioxide (Chemours) 62.3g, lemon yellow PY81 (H10G, Clariant) 15.3g, phthalocyanine blue (Nantong Zhengyan production) 0.16g, soft carbon black (N550, German Orion production) 0.15g, deionized water 64.3g, thickener BYK-425 (Germany BY...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com