A kind of environmental protection wear-resisting coating for automobile and preparation method thereof

A technology of wear-resistant coatings and wear-resistant fillers, applied in coatings and other directions, can solve problems such as low temperature resistance, poor water resistance, and poor wear resistance, and achieve excellent wear resistance and water resistance, good water resistance, and enhanced wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

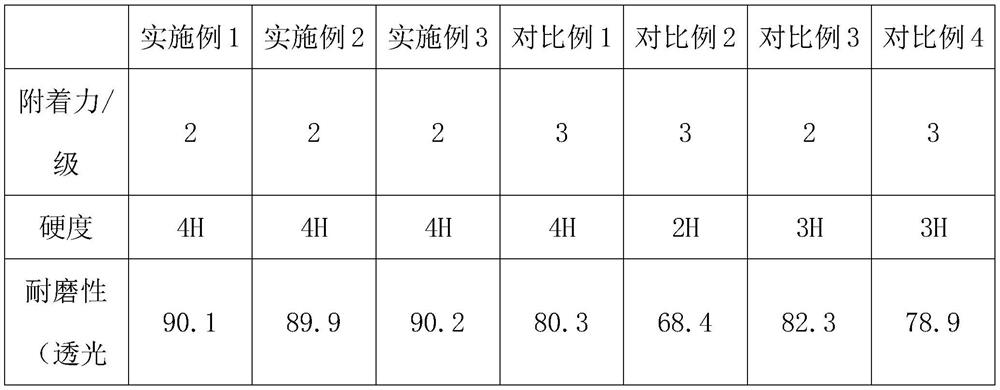

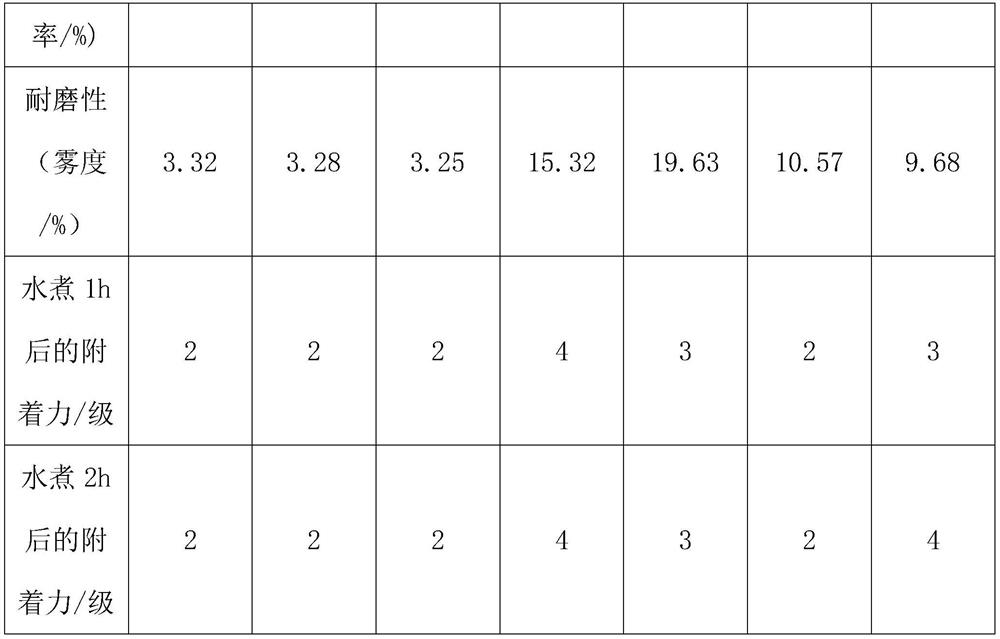

Examples

preparation example Construction

[0048] The preparation method of the environment-friendly wear-resistant paint for automobiles comprises the following steps:

[0049] Step S1, adding the modified polyester resin into N,N-dimethylformamide, and heating to dissolve it;

[0050] Step S2, add styrene, wear-resistant filler and lubricating filler, stir at 200r / min at room temperature for 30-40min, add defoamer, anti-settling agent, leveling agent and ultraviolet absorber, continue stirring at 200r / min for 20-30min;

[0051] Step S3, finally adding a curing agent and stirring for 10 minutes to obtain an environmentally friendly and wear-resistant coating for automobiles.

Embodiment 1

[0053] An environmentally friendly wear-resistant coating for automobiles, made of the following raw materials in parts by weight: 50 parts of modified polyester resin, 2.5 parts of wear-resistant filler, 1 part of lubricating filler, 1 part of curing agent, 0.2 part of defoaming agent, anti-settling agent 0.3 parts, 0.2 parts of leveling agent, 0.1 parts of UV absorber, 5 parts of styrene, 40 parts of N,N-dimethylformamide;

[0054] The paint is made by the following steps:

[0055] Step S1, adding the modified polyester resin into N,N-dimethylformamide, and heating to dissolve it;

[0056] Step S2, add styrene, wear-resistant filler and lubricating filler, stir at room temperature 200r / min for 30min, add defoamer, anti-settling agent, leveling agent and ultraviolet absorber, and continue to stir at 200r / min for 20min;

[0057] Step S3, finally adding a curing agent and stirring for 10 minutes to obtain an environmentally friendly and wear-resistant coating for automobiles. ...

Embodiment 2

[0059] An environmentally friendly wear-resistant coating for automobiles, made of the following raw materials in parts by weight: 55 parts of modified polyester resin, 2.8 parts of wear-resistant filler, 1.3 parts of lubricating filler, 1.3 parts of curing agent, 0.25 parts of defoaming agent, anti-settling agent 0.35 parts, 0.25 parts of leveling agent, 0.15 parts of UV absorber, 6.5 parts of styrene, 45 parts of N,N-dimethylformamide;

[0060] The paint is made by the following steps:

[0061] Step S1, adding the modified polyester resin into N,N-dimethylformamide, and heating to dissolve it;

[0062] Step S2, add styrene, wear-resistant filler and lubricating filler, stir at room temperature for 35 minutes at 200r / min, add defoamer, anti-settling agent, leveling agent and ultraviolet absorber, continue to stir at 200r / min for 25min;

[0063] Step S3, finally adding a curing agent and stirring for 10 minutes to obtain an environmentally friendly and wear-resistant coating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com