Preparation method and application of hydrogel material

A hydrogel and solution technology is applied to the preparation of hydrogel materials and the field of new fireproof materials, which can solve the problems of poor mechanical properties and easy volatility of hydrogels, and achieve stable water content, low energy consumption and simple preparation method. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Preparation of hydrogel materials

[0033] (1) Prepare 20 mL of 0.5 mol / L NaCl solution, and dissolve 0.14 g of sodium dodecylbenzenesulfonate in the solution, and stir evenly to obtain a preconfigured solution, which is the mass percentage of sodium dodecylbenzenesulfonate is 7 wt%.

[0034] (2) Add 1 mol / L acrylamide, 0.01 mol / L octadecyl methacrylate, and 0.001 mol / L initiator to the mixed solution in sequence, stir well and pass through N 2 10 min to remove the oxygen in the solution to prepare a pre-polymerization solution;

[0035] (3) Pour the pre-polymerization solution into a glass mold and irradiate with 365 nm ultraviolet light for 12 h to form a hydrogel;

[0036] (4) Take the hydrogel out of the mold and soak it in 0.1 mol / L lithium chloride solution for 3 h to obtain the hydrogel material.

Embodiment 2-4

[0038] In Example 2-4, steps (1), (3) and (4) are the same as in Example 1, except that the molar concentrations of acrylamide, stearyl methacrylate and initiator in step (2) are different , the concentration of each component in step (2) in Example 2-4 is shown in Table 1. The hydrogel materials prepared in each embodiment were used for the fire performance test.

[0039] The concentration of acrylamide, stearyl methacrylate and initiator in table 1 embodiment 1-4

[0040] Example Acrylamide / mol / L Octadecyl methacrylate / mol / L Initiator / mol / L Example 1 1 0.01 0.001 Example 2 2 0.02 0.002 Example 3 3 0.03 0.003 Example 4 4 0.04 0.004

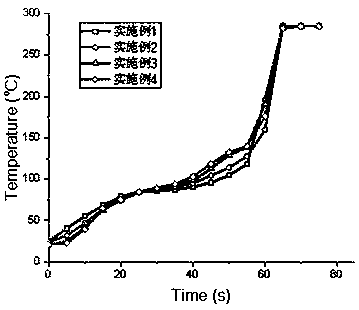

[0041] The hydrogel material prepared by embodiment 1-4 is used for fire performance test, and test result is as follows figure 1 shown. The hydrogels with different components all exhibited excellent fire performance, and could not be penetrated by the flame under the high temperature flame ...

Embodiment 5-14

[0043] In Example 5-14, steps (1) to (3) are the same as in Example 1, except that the hygroscopic chloride salt solution soaked in step (4) is different, and the steps in Example 5-14 ( 4) The hygroscopic chloride salt solution is shown in Table 2.

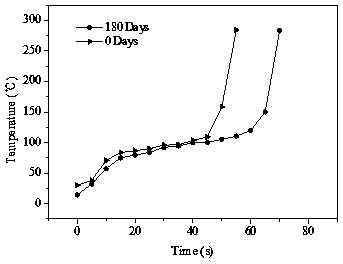

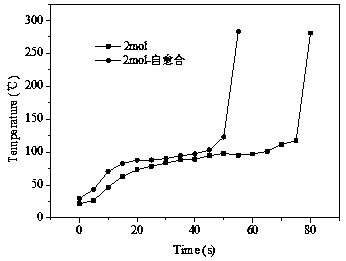

[0044] The hydrogel materials prepared in Examples 5-14 were used for the fire performance test and the water loss rate test, and the specific test contents are shown in Table 2. Test results such as Figure 2-Figure 5 shown.

[0045] The composition, concentration and the test experiment of each embodiment of hygroscopic chloride salt solution in table 2

[0046] Example hygroscopic chloride salt Solution concentration / mol / L Test content Example 5 lithium chloride saturation concentration Fire performance test, 180-day exposure fire performance test Example 6 lithium chloride 2 Fire performance test, through cut fire performance test Example 7 magnesium chloride 0.1 Water loss test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com