A kind of sulfurized nano zero-valent iron particles and its preparation method and application

A technology of nano-sized zero-valent iron and particles, which is applied in iron sulfide, chemical instruments and methods, inorganic chemistry, etc., can solve the limitation of large-scale production and application of sulfide-type nano-zero-valent iron particles, reduce the selectivity and reduction of target pollutants Conversion efficiency, consumption of large reduction capacity and other issues, to achieve the effect of high reduction conversion efficiency, low production cost and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

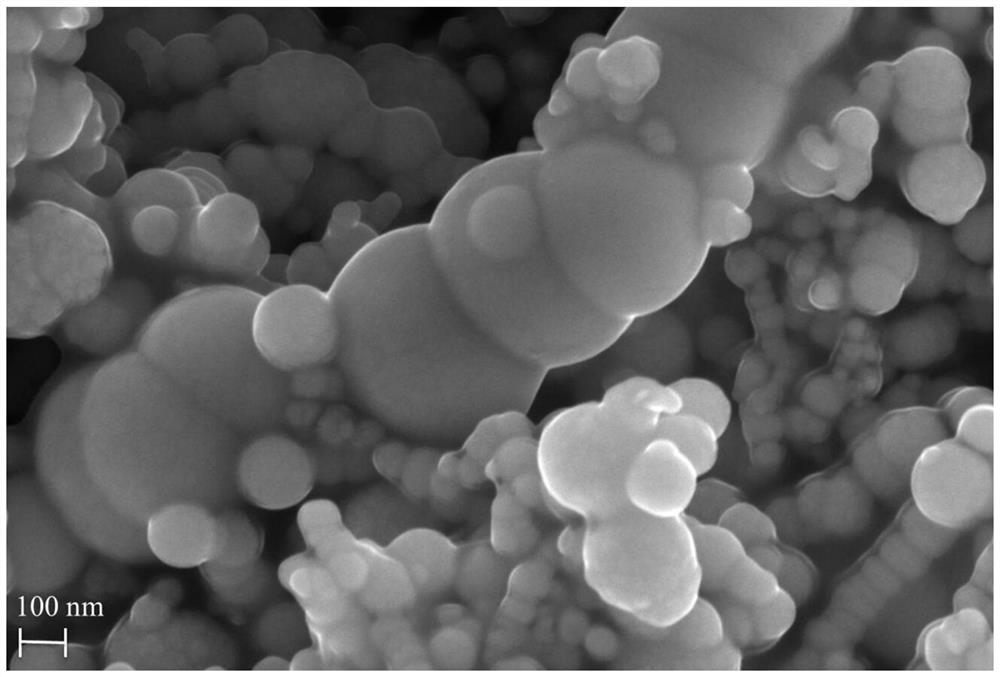

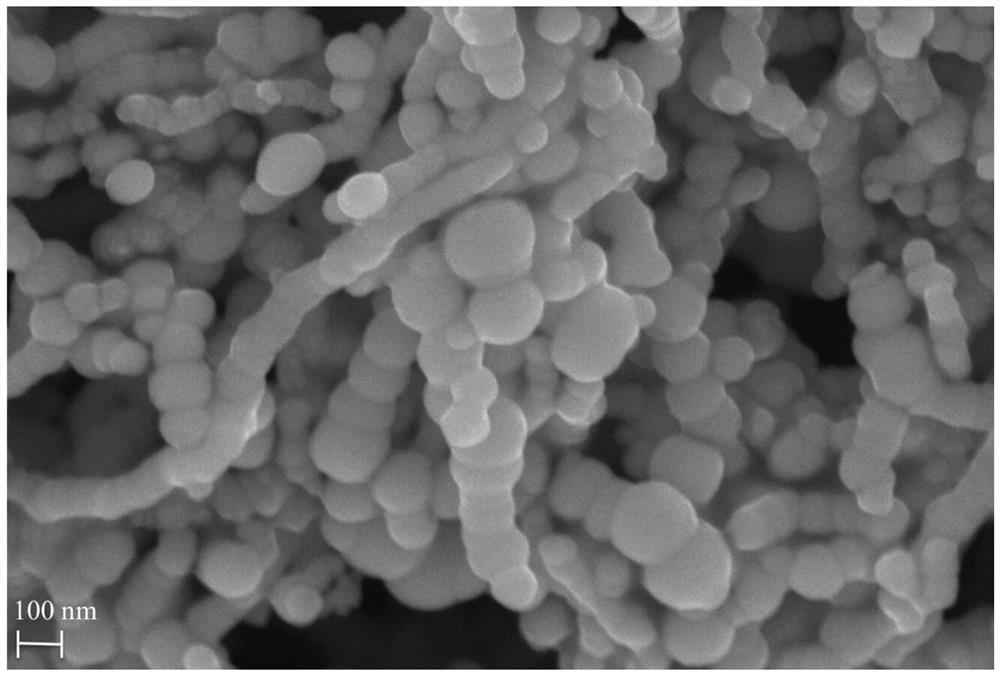

[0033] A vulcanized nano-zero-coated iron particle, the preparation method thereof includes the following steps:

[0034] 1) FECL with 60 ml of concentration of 0.2 mol / L 2 The solution was added to the reactor, and the 180 ml concentration of 0.3 mol / L was stirred while stirring. 4 Solution dropped to FECL 2 In the solution, the reaction was continued after 15 min, and then the precipitate was allowed to concentrate, remove the supernatant, washed 4 times with high purity water to obtain nano-zero-valent iron particles (NZVI);

[0035] 2) Disperse the nano-zero-coated iron particles in 420 ml of ethanol, then add 0.0096 g of single subjection sulfur powder (single sulfur powder, nano-zero-core particles of 0.025: 1), stir for 12 h, and then stand again, The supernatant was removed, and the solid product was washed 4 times with ethanol to obtain a sulfide nano zo-iron particles (S-NZVI).

[0036] Performance Testing:

[0037] 1) Test:

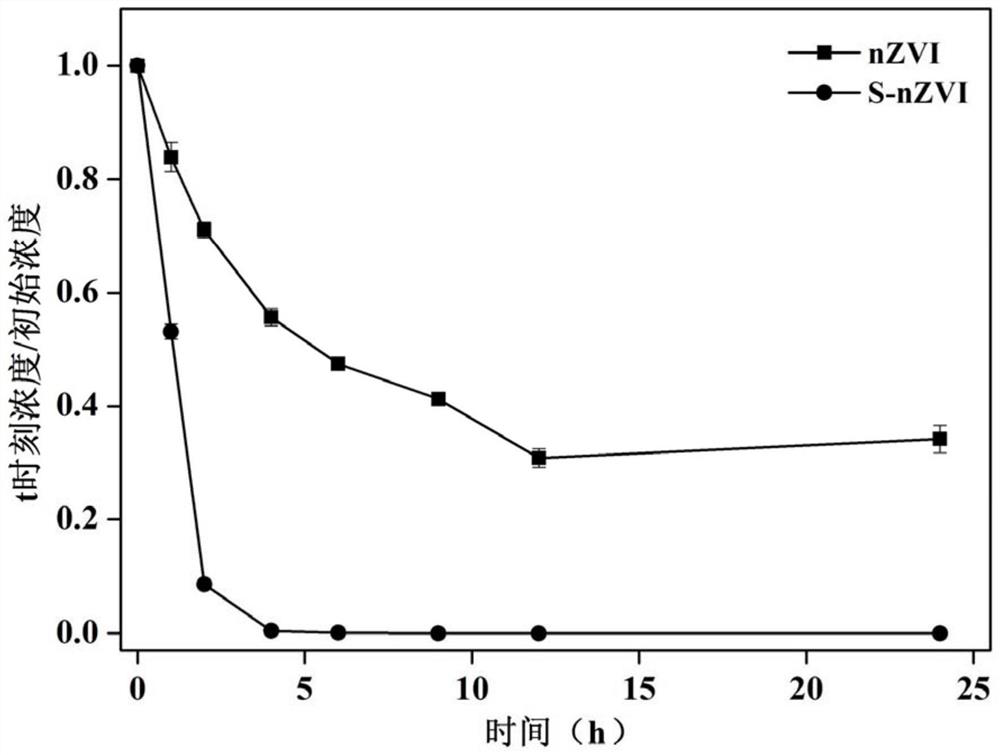

[0038] The sulfide nano-zero-valent iron...

Embodiment 2

[0050] Referring to the preparation method of Example 1, the molar ratio (referred to as S / Fe molar ratio of nano-zero-coated iron particles) was adjusted, 0.015: 1, 0.025: 1, 0.05: 1, 0.1: 1, and 0.25: 1, respectively. , The prepared S-NZVi obtained by different S / Fe molar ratios, referring to the method of Embodiment 1 to test NZVI and different S / FE molar ratio of S-NZVI to TBBPA degradation effect, test results Figure 7 Indicated.

[0051] Depend on Figure 7 It can be seen that the molar ratio of single-tape sulfur and nano-zero-ferrous particles is 0.025: 1, and the preparation of S-NZVI's degradation effect is best.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com