A kind of preparation method of pure phase metal silicide

A metal silicide, pure-phase technology, applied in the direction of metal silicide, etc., can solve the problem of difficulty in the target silicide product, and achieve the effect of flexible and convenient method, mild synthesis conditions, and lower reaction enthalpy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

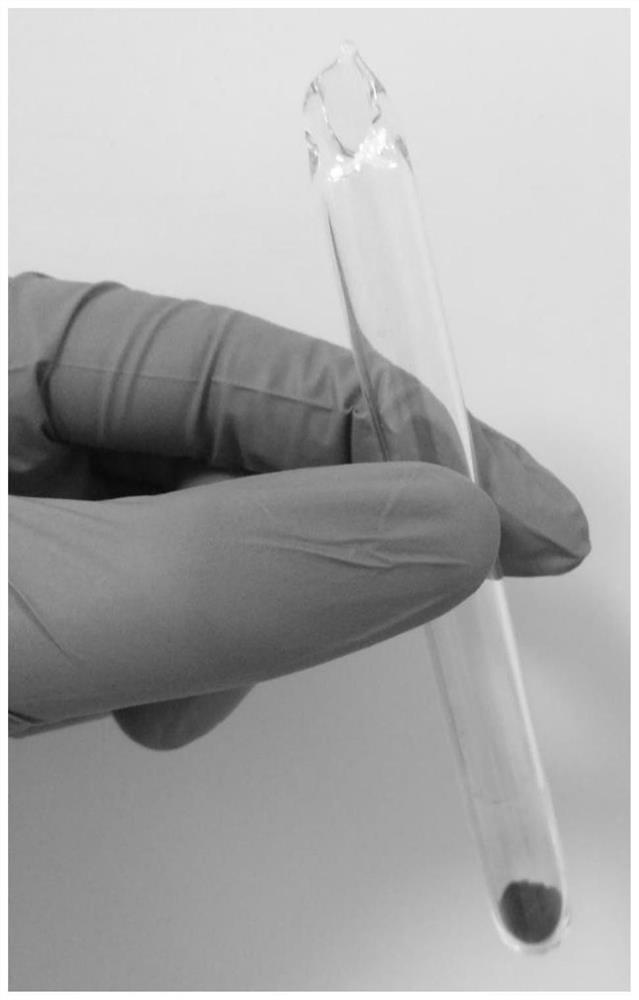

Embodiment 1

[0024] Preparation of RuSi. RuCl 3 (103.8mg, 0.5mmol), Si powder (14.0mg, 0.5mmol) and Mg powder (29.2mg, 1.2mmol) were fully ground and mixed under the irradiation of an infrared lamp, and then transferred to a quartz tube. The quartz tube that raw material mixture is housed is connected with vacuum pumping device, when vacuum degree is drawn to less than 1Pa, seal this quartz tube ( figure 1 ). The sealed quartz tube was calcined at 700° C. for 4 h with a heating rate of 3° C. / min. After the quartz tube was cooled to room temperature, the obtained black powder was dissolved in 0.5mol / L H 2 SO 4 Soak in the solution for 1h to remove the by-product MgCl 2 and excess Mg powder. After three times of centrifugal cleaning with water and ethanol, put it in a vacuum drying oven and dry it at 50°C. After drying, a RuSi sample with a mass of about 60 mg can be obtained.

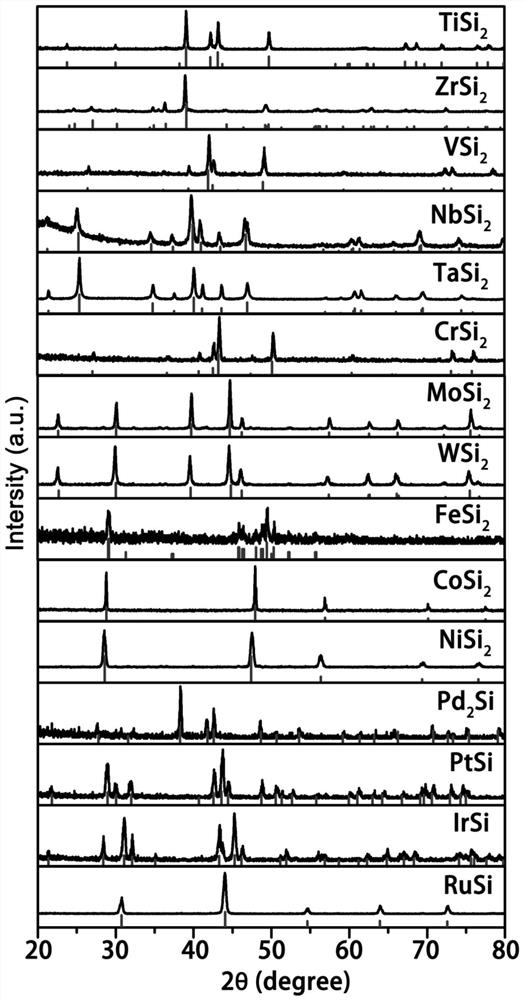

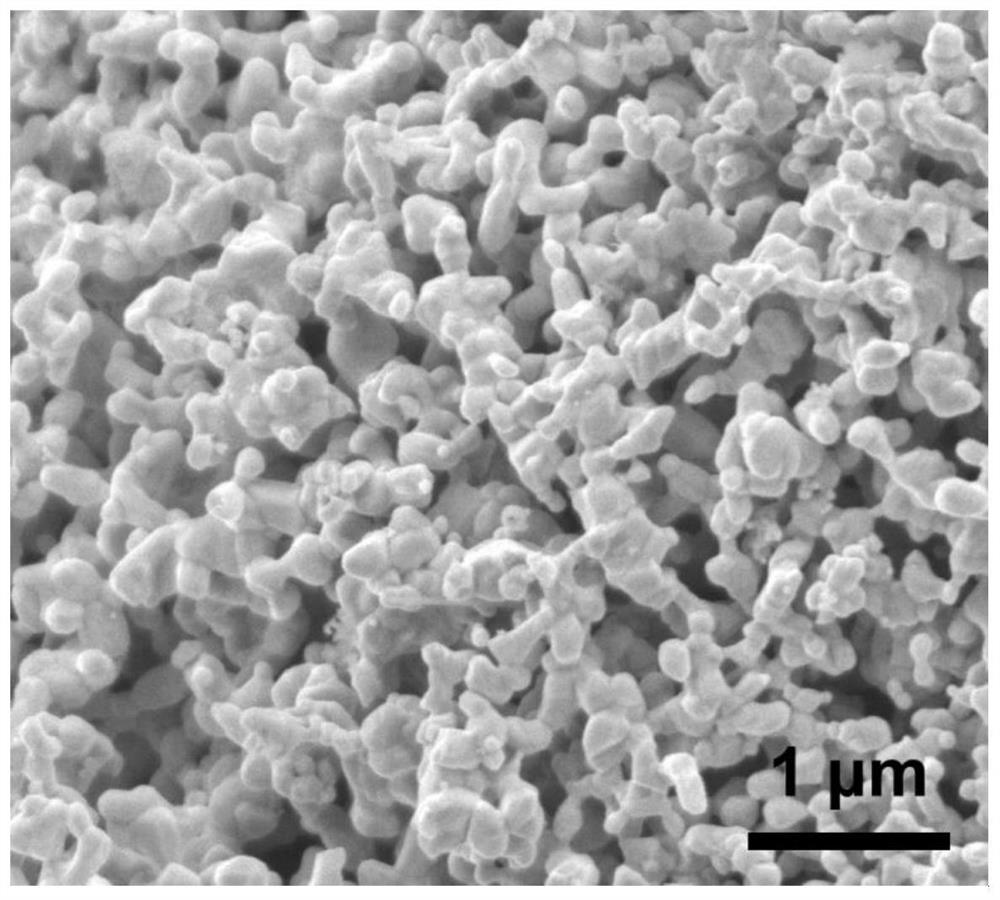

[0025] Some structural and morphological studies were carried out on the samples prepared by the above meth...

Embodiment 2

[0027] Preparation of IrSi. IrCl 3 (149.3mg, 0.5mmol), Si powder (14.0mg, 0.5mmol) and Mg powder (18.2mg, 0.75mmol) were fully ground and mixed under the irradiation of an infrared lamp, and then transferred to a quartz tube. Connect the quartz tube containing the raw material mixture to a vacuum device, and seal the quartz tube when the vacuum is lower than 1 Pa. The sealed quartz tube was calcined at 800° C. for 4 h with a heating rate of 3° C. / min. After the quartz tube was cooled to room temperature, the obtained black powder was dissolved in 0.5mol / L H 2 SO 4 Soak in the solution for 1h to remove the by-product MgCl 2 . After three times of centrifugal cleaning with water and ethanol, put it in a vacuum drying oven and dry it at 50°C. After drying, an IrSi sample with a mass of about 110 mg is obtained. The XRD pattern of this sample is shown in figure 2 .

Embodiment 3

[0029] Preparation of PtSi. PtCl 4(168.4mg, 0.5mmol), Si powder (14.0mg, 0.5mmol) and Mg powder (24.3mg, 1.0mmol) were fully ground and mixed under the irradiation of an infrared lamp, and then transferred to a quartz tube. Connect the quartz tube containing the raw material mixture to a vacuum device, and seal the quartz tube when the vacuum is lower than 1Pa. The sealed quartz tube was calcined at 800° C. for 4 h with a heating rate of 3° C. / min. After the quartz tube was cooled to room temperature, the obtained black powder was dissolved in 0.5mol / L H 2 SO 4 Soak in the solution for 1h to remove the by-product MgCl 2 . After three times of centrifugal cleaning with water and ethanol, put it in a vacuum drying oven and dry it at 50°C. After drying, a PtSi sample with a mass of about 110 mg is obtained. The XRD pattern of this sample is shown in figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com