Device and process for recovering sulfur by treating low-concentration acid gases

A technology for acid gas and sulfur recovery, applied in the preparation/purification of sulfur, sulfur compounds, inorganic chemistry, etc., can solve the problems of inability to meet emission requirements and high concentration, achieve small footprint, short process flow, and reduced operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

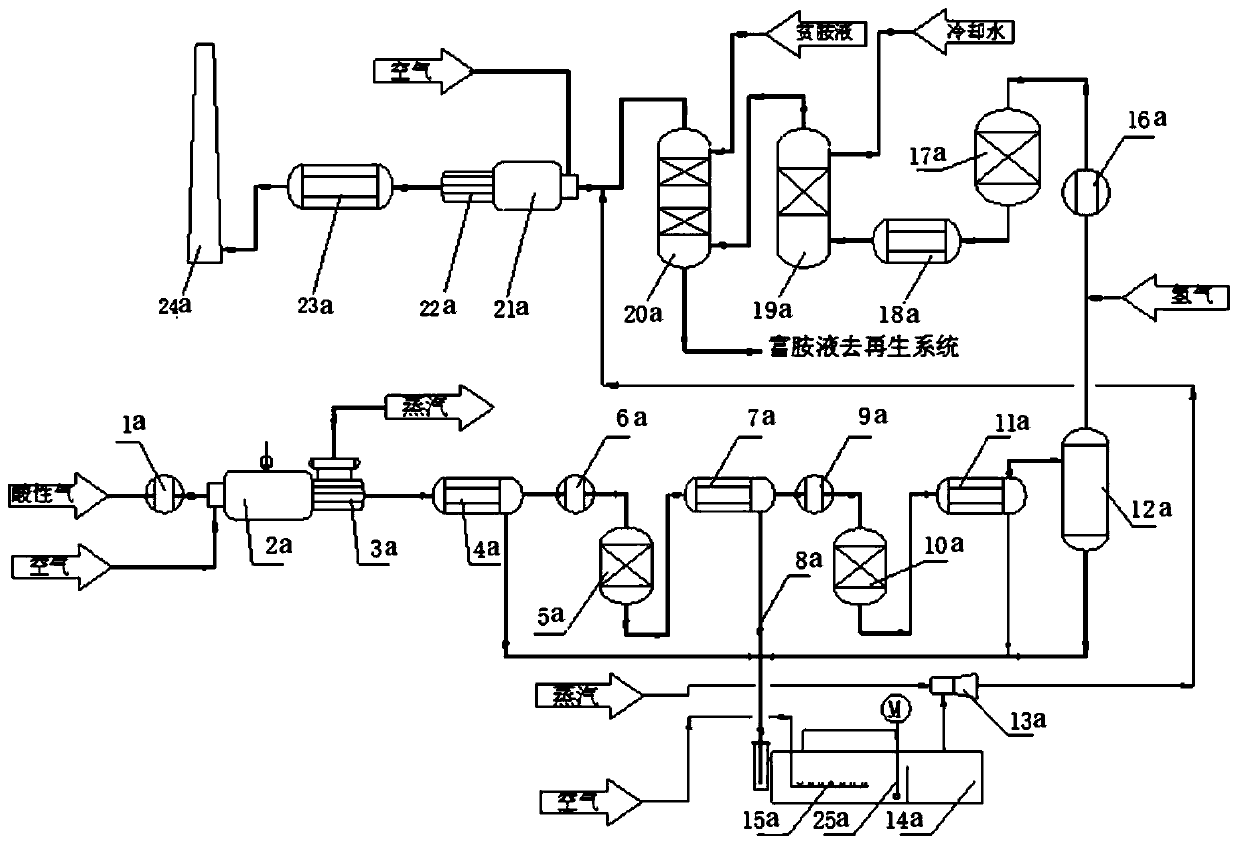

[0070] A set of 6000 tons / year sulfur recovery device of coal chemical methanol plant adopts the present invention as figure 1 shown in the sulfur recovery unit for processing. The specific selection and loading amount of catalysts in each reactor are shown in Table 2 below.

[0071] Table 2 Catalyst loading

[0072]

[0073]

[0074] The 100% load of acid gas treated by sulfur plant is 2400m 3 / h, H 2 S volume content 20-30%, the rest is mainly CO 2 , with an appropriate amount of oxygen entering the sulfur furnace 1 for combustion. The temperature of the sulfur furnace 1 is controlled at about 1050°C. The process gas generated after combustion passes through the waste heat boiler 3 and is cooled. At the same time, 0.5MPa (g) low-pressure steam is generated. After the temperature drops to 320°C, it enters the primary condensing cooler 4 and cools down to 160°C. The condensed liquid sulfur is separated from the process gas at the outlet of the tube side, and flows o...

Embodiment 2

[0081] A set of 4000 tons / year sulfur recovery device of natural gas purification plant adopts the present invention as figure 1 shown in the sulfur recovery unit for processing. The specific selection and loading amount of catalysts in each reactor are shown in Table 3 below.

[0082] Table 3 Catalyst selection and loading

[0083]

[0084]

[0085] The 100% load of acid gas treated by sulfur plant is 650m 3 / h, H 2 S volume content 50-60%, the rest is mainly CO 2 The temperature of the combustion furnace is controlled at about 1050°C. The process gas generated after combustion is cooled after passing through the waste heat boiler 3. At the same time, 0.5MPa (g) low-pressure steam is generated, and the temperature of the process gas drops. After reaching 320°C, it enters the first-stage condensing cooler 4, and cools to 160°C. The condensed liquid sulfur is separated from the process gas at the outlet of the tube side, and flows out from the bottom into the sulfur ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com