Three-layer composite waterproof corrugated board and preparation technology thereof

A technology of corrugated cardboard and preparation process, which is applied in the field of corrugated paper, can solve the problems of corrugated paper strength decrease, corrugated paper poor moisture resistance, corrugated paper strength low, etc., and achieve the effect of increasing strength, increasing waterproof performance, and improving waterproof and moisture-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-3

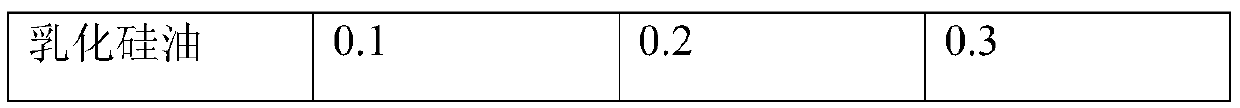

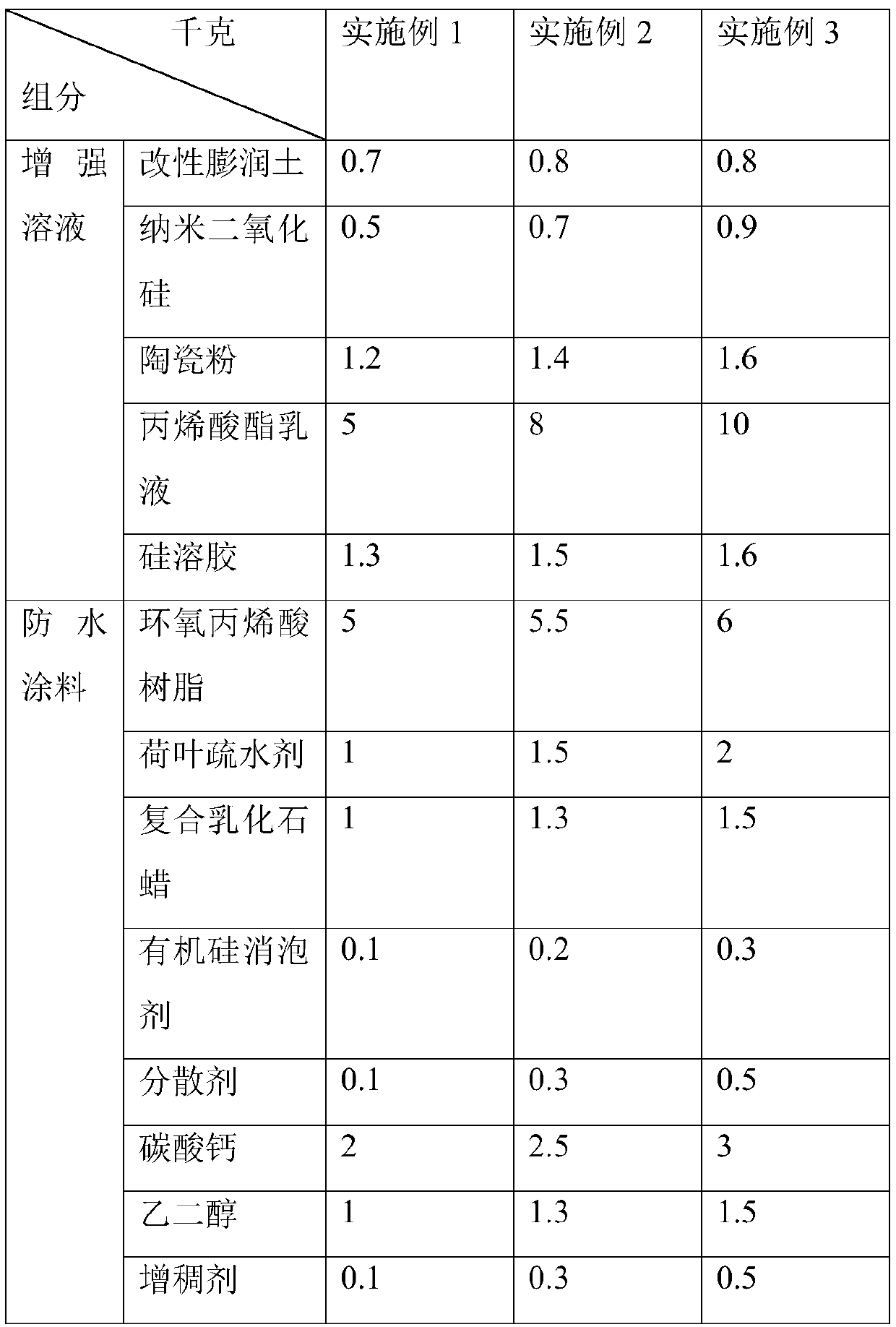

[0037]In Preparation Example 1-3, the paraffin wax is selected from the 60# paraffin wax sold by Jinan Haiwei Chemical Co., Ltd., the rosin resin is selected from the rosin resin sold by Dongguan Shuangteng Rubber Sweater Co., Ltd., and the emulsified silicone oil is selected from Hebei Duoliwei Chemical Industry The CR100 emulsified silicone oil sold by Shenzhen Yichang Xingye Trading Co., Ltd., the dimethyl silicone oil is selected from the KF96-350CS type simethicone oil sold by Shenzhen Yichang Xingye Trading Co., Ltd., and the polyethylene is selected from the LH506 type sold by Suzhou Jinsulian Plastic Chemical Co., Ltd. polyethylene.

[0038] Preparation Example 1: (1) According to the ratio of raw materials in Table 1, put 2kg of paraffin wax and 0.5kg of rosin resin into the reactor, heat to 80°C to melt, mix well, add 0.5kg of polyethylene, and raise the temperature to 160°C, mix well;

[0039] (2) Add 0.3kg of simethicone oil, 0.1kg of emulsified silicone oil and 3...

preparation example 2

[0043] Preparation Example 2: (1) According to the ratio of raw materials in Table 1, put 2.5kg of paraffin wax and 0.8kg of rosin resin into the reactor, heat to 85°C to melt, mix well, add 0.8kg of polyethylene, and raise the temperature to 170°C, mix well;

[0044] (2) Add 0.4kg of simethicone oil, 0.2kg of emulsified silicone oil and 3.5kg of dehydrated alcohol with a mass fraction of 93% to the resultant of step (1), and mix well.

preparation example 3

[0045] Preparation Example 3: (1) According to the raw material ratio in Table 1, put 3.0kg of paraffin wax and 1.0kg of rosin resin into the reactor, heat to 90°C to melt, mix well, add 1.0kg of polyethylene, and raise the temperature to 180°C, mix well;

[0046] (2) Add 0.6kg of simethicone oil, 0.3kg of emulsified silicone oil and 4kg of dehydrated alcohol with a mass fraction of 95% to the resultant of step (1), and mix well.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bursting strength | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com