Decorative gypsum terrace and decorative gypsum board and preparation method thereof

A technology for gypsum board and gypsum, which is applied to supply devices, manufacturing tools, ceramic molding machines, etc., can solve problems such as strength to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

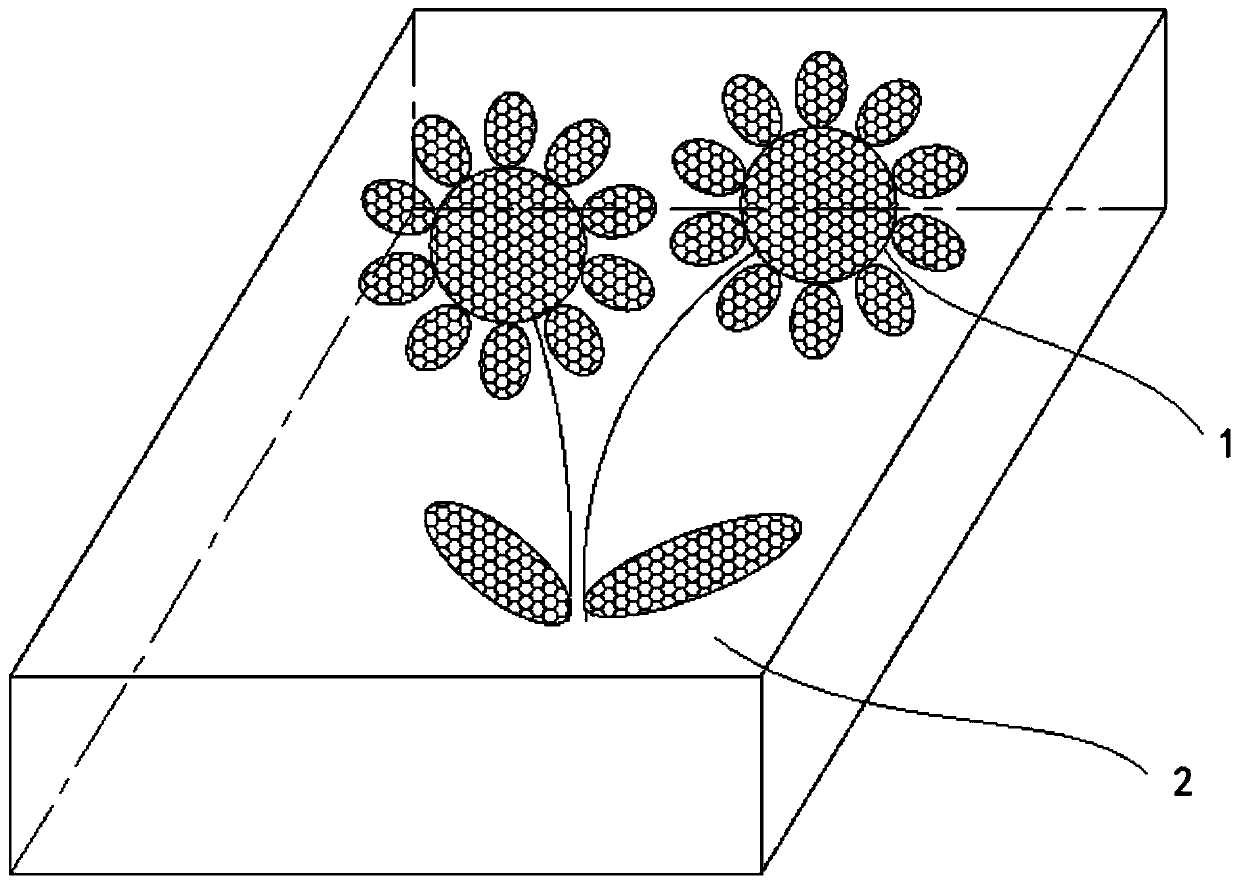

[0023] One, such as figure 1 As shown, this embodiment provides a decorative gypsum floor and a decorative gypsum board, both of which include a colored patterned gypsum block 1 and a main gypsum layer 2, the main gypsum layer 2 is wrapped around the colored patterned gypsum block 1, and the colored patterned gypsum layer 2 The patterned gypsum block 1 is integrally connected with the main gypsum layer 2 .

[0024] Two, the preparation method of described decorative gypsum floor and decorative gypsum board, comprises the steps:

[0025] Step 1, preparation of colored pattern gypsum block: design the pattern gypsum layer manufacturing mold according to the desired pattern pattern ( figure 1 The pattern in the pattern can also be designed into other various required hollow patterns), the colored gypsum color paste is poured into the patterned gypsum layer to make a mold, and the colored patterned gypsum block is obtained after being completely dry (usually greater than or equal...

Embodiment 2

[0033] The colored gypsum color paste in step 1 in this embodiment includes 95 parts of α-gypsum powder, 4 parts of water-based color paste, 0.5 part of dispersant, 0.5 part of sodium citrate, and 0.5 part of water reducing agent in parts by weight.

[0034] The main gypsum casting material described in step 2 includes 85 parts of alpha gypsum powder, 4 parts of water-based color paste, 0.5 part of dispersant, 0.5 part of retarder, 0.5 part of water reducer and 10 parts of white marble powder in parts by weight.

[0035] All the other steps are the same as in Example 1.

Embodiment 3

[0037] The colored gypsum color paste in step 1 in this embodiment includes 80 parts of α-gypsum powder, 10 parts of water-based color paste, 1 part of dispersant, 1 part of sodium citrate, and 2 parts of water reducing agent in parts by weight.

[0038] The main gypsum casting material described in step 2 includes 60 parts of α-gypsum, 10 parts of water-based color paste, 1 part of dispersant, 1 part of retarder, 2 parts of water reducing agent and 40 parts of sandstone powder in parts by weight; Step is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com