Circuit board punching device for applicant electronics

A technology that applies electronics and circuit boards. It is applied in metal processing and other directions. It can solve problems such as adverse effects, inconvenient use by users, and complicated operations, and achieve the effect of meeting the requirements of use and convenient and quick punching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

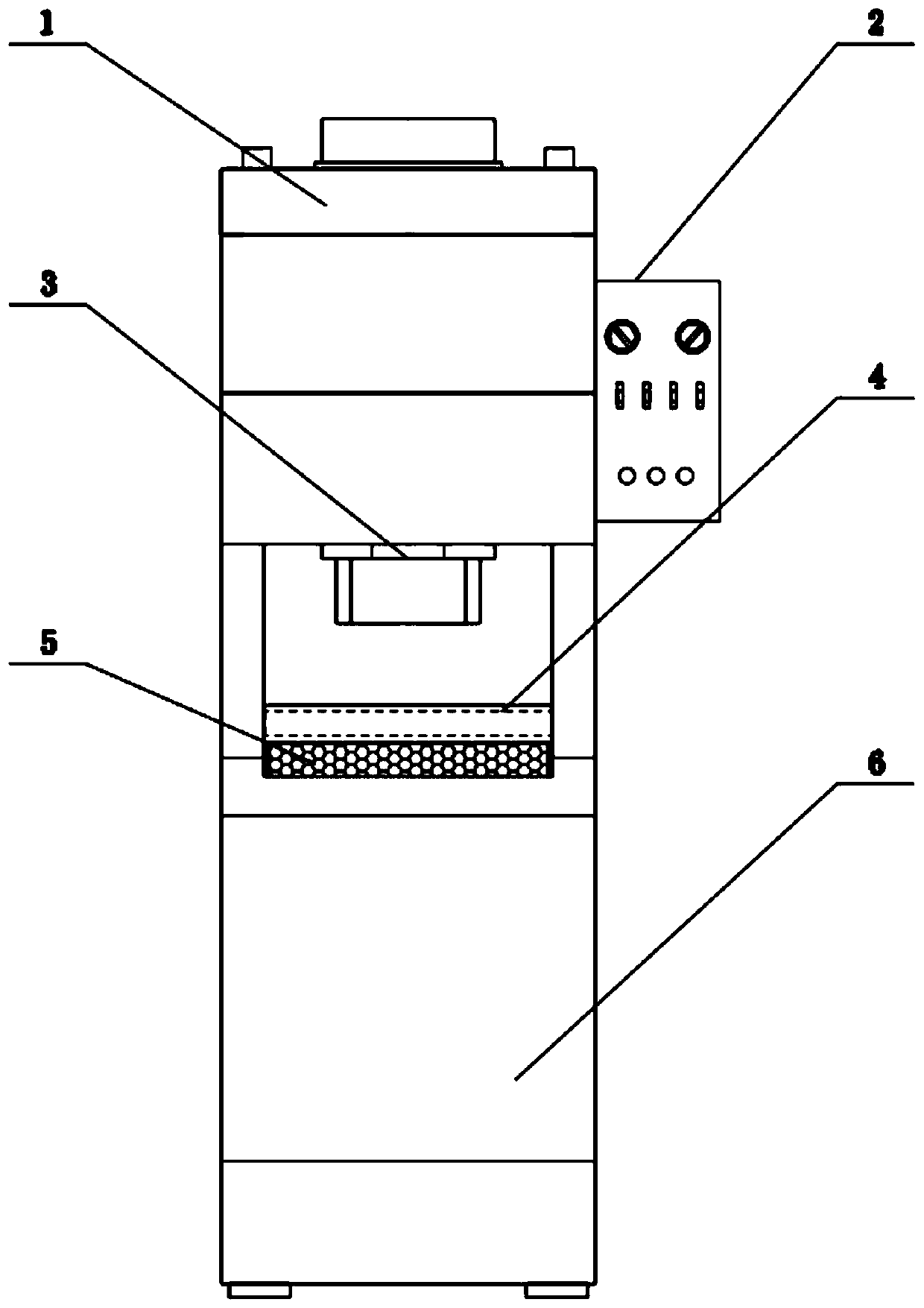

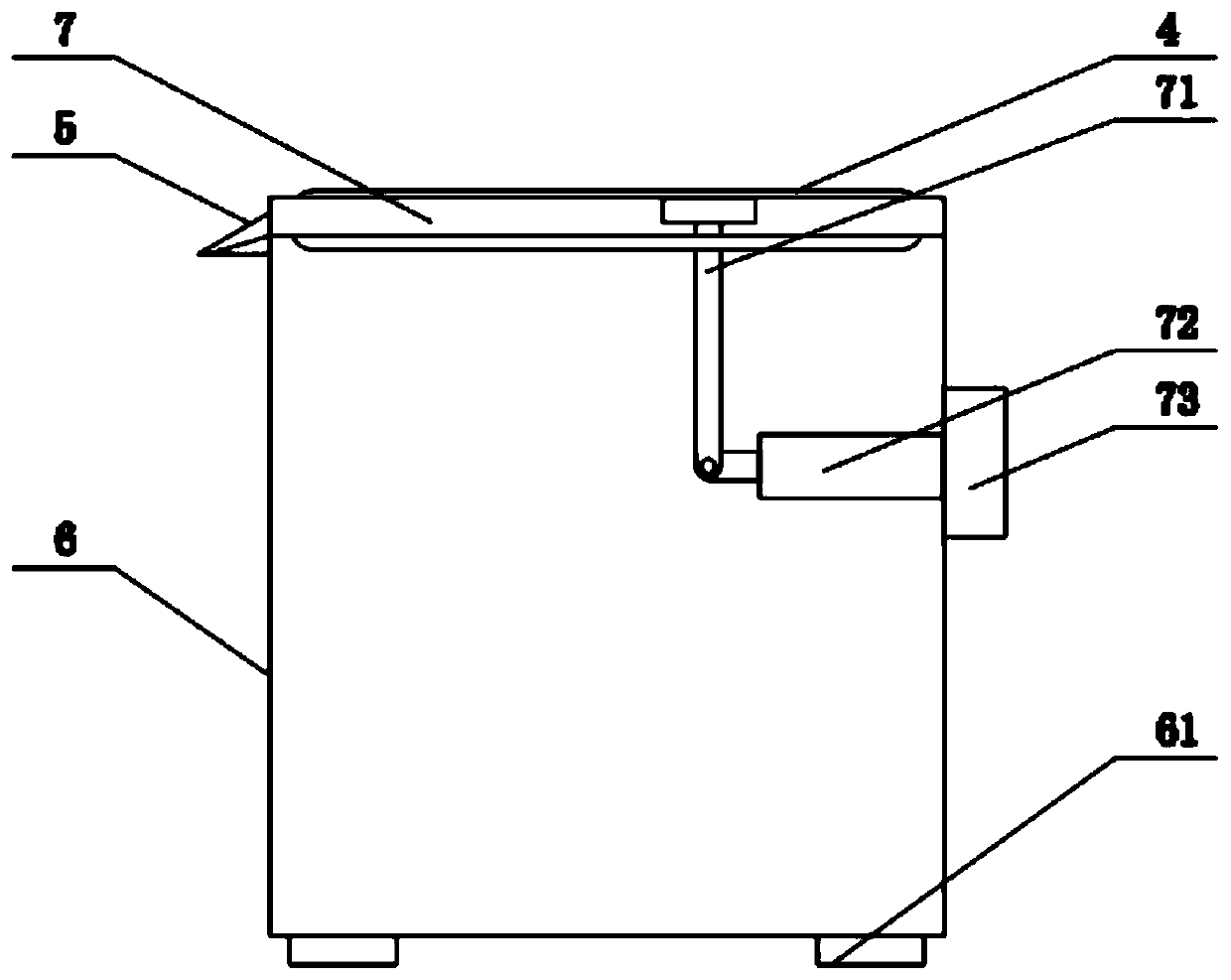

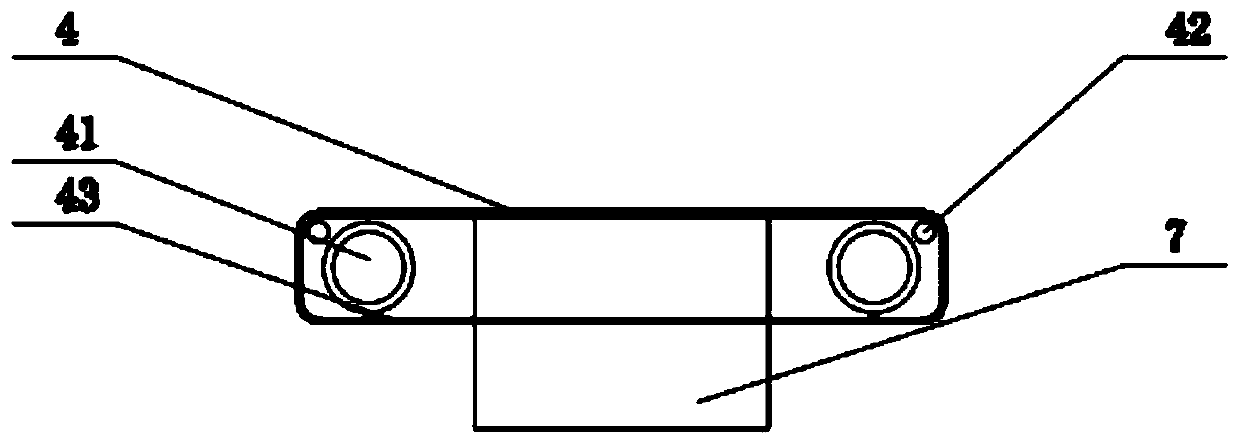

[0021] see Figure 1-Figure 6 As shown, the technical solution adopted in this specific embodiment is: it includes a hydraulic mechanism 1, a control box 2, a stamping mechanism 3, a transmission device 4, a discharge plate 5, a base 6, and an air pressure mechanism 7; A stamping mechanism 3 is arranged below, and the stamping mechanism 3 is movably installed above the base 6, the control box 2 is installed on the right side of the hydraulic mechanism 1, the transmission device 4 is set on the top of the base 6, and the discharge plate 5 is set on the top of the transmission device 4. In the front, the air pressure mechanism 7 is fixedly installed on the rear side of the base 6. The air pressure mechanism 7 includes a steering rod 71, a telescopic rod 72, a fixed seat 73, and a punching plate 74; one end of the telescopic 72 is connected with the fixed seat 73 , the other end of telescoping rod 72 is flexibly connected with the bottom of steering rod 71, and the top of steerin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com