A NC Milling Tooling That Can Reduce Workpiece Deformation

A CNC milling and tooling technology, which is applied to metal processing equipment, milling machines, milling cutters, etc., can solve the problems of inaccurate coolant injection range, unguaranteed product quality, increased coolant usage, etc., to reduce workpiece deformation , improve the processing quality, reduce the effect of thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

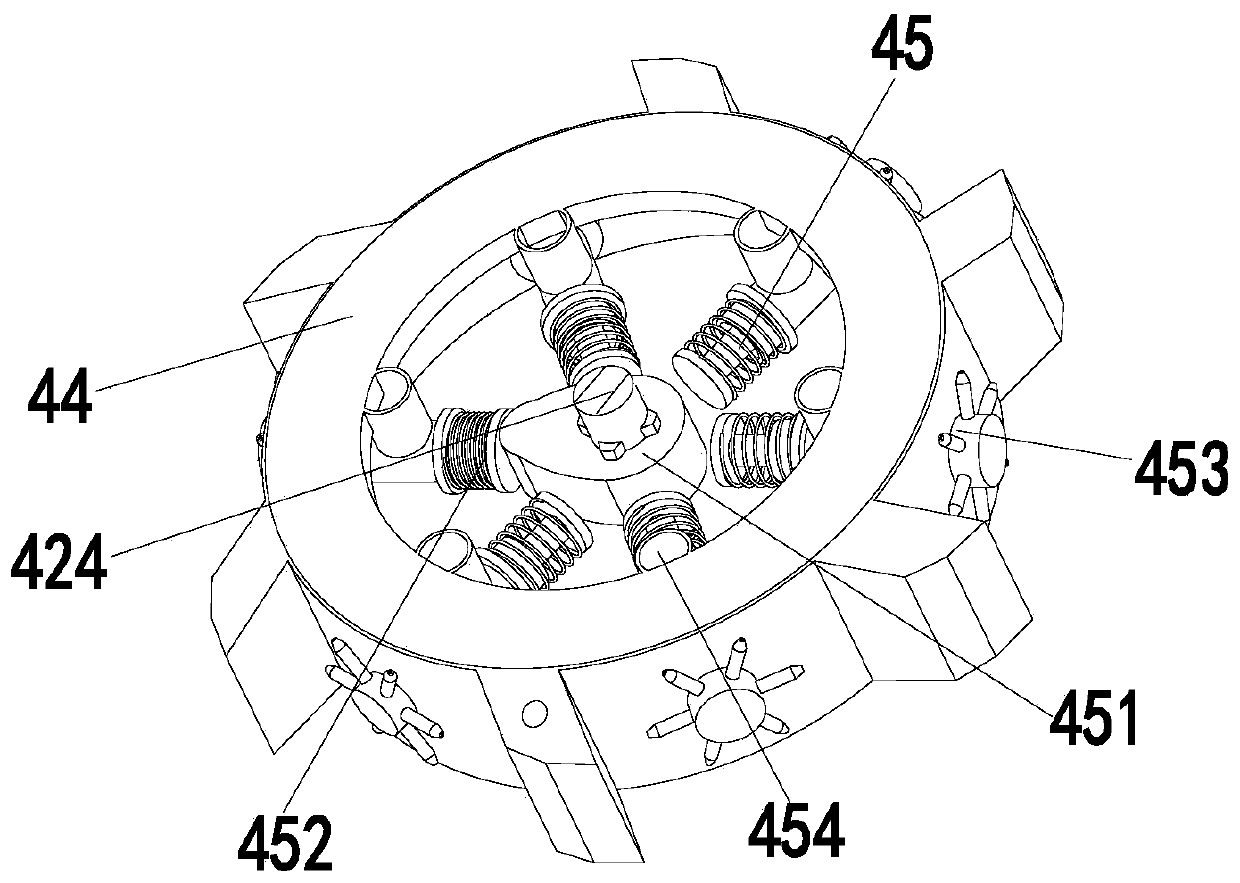

[0029] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 6 , to further elaborate the present invention.

[0030] A CNC milling tooling capable of reducing workpiece deformation, comprising a table 1, a moving frame 2, an electric slider 3 and a milling mechanism 4, the upper end of the table 1 is equipped with a moving frame 2, and the lower end of the moving frame 2 is installed with an electric slider Block 3, the lower end of the electric slider 3 is equipped with a milling mechanism 4, and the structure, principle and control method of the electric slider 3 are all prior art; wherein:

[0031] The mobile frame 2 includes a vertical board 21 and an electric skateboard 22, the number of the vertical boards 21 is two, and the two vertical boards 21 are symmetrically installed on the upper end of the platform 1, and an electric skateboard is installed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com