Green tea dust removal device

A dust removal device and technology for green tea, which are applied in the directions of tea treatment before extraction, solid separation, and separation of solids from solids by air flow, can solve the problems of poor cleaning effect of tea leaves, affecting the quality of tea leaves, etc., and improve anti-oxidation. effect, improve dust removal effect, bright color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

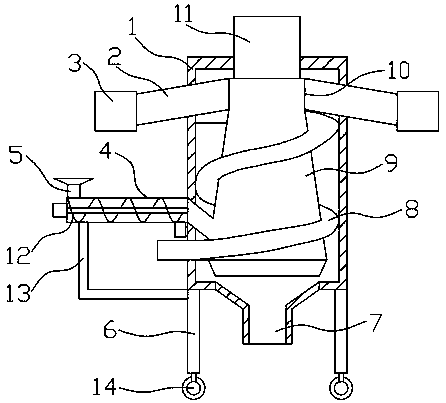

[0021] Such as figure 1 , 2 , shown in 4, a kind of dedusting device of green tea comprises casing 1, and the bottom of casing 1 is provided with discharge pipe 7, and the top of casing 1 is connected with suction pipe 11, and the lower end of suction pipe 11 is connected with dust removal chamber 9, and dust removal One side of the chamber 9 is provided with a feed port 16, the feed port 16 is connected with a feed pipe 4, the top of the feed pipe 4 away from the feed port 16 is connected with a feed pipe 5, and the bottom of the feed pipe 4 is connected with a branch bracket 13. A helical blade 12 is connected inside the material guide pipe 4, and the helical blade 12 is driven by a motor. The present invention separates the tea leaves from the dust by wind force, and the separation effect is good, and the damage to the tea leaves is small. The suction pipe 11 makes the air body inside the dust removal chamber 9 flow upward, which not only ensures that the tea leaves will n...

Embodiment 2

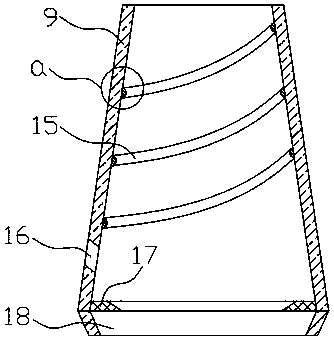

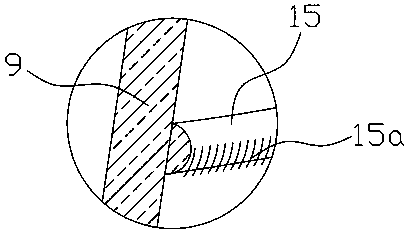

[0028] This embodiment is a further optimization scheme on the basis of embodiment 1: as figure 2 , 3As shown, the bottom of the inner wall of the dust removal chamber 9 is connected with a closing port 18, the inner wall of the dust removing room 9 at the upper end of the closing port 18 is connected with a eaves 17, the inner wall of the dust removing room 9 is surrounded by a spiral strip 15, and the top of the spiral strip 15 is connected with a spiral strip extending to the lower end of the spiral strip 15. The elastic rope 15a of the inner wall of the dust removal chamber 9, the size of the mouth 18 of the dust removal chamber 9 is consistent with the size of the discharge pipe 7, so that the tea leaves that have been dedusted can be completely taken out through the discharge pipe 7, and the dust removal chamber 9 has two small, middle The large shape can not only prevent the tea leaves from falling, but also enhance the wind body and improve the dust removal effect of ...

Embodiment 3

[0032] Such as Figure 1~4 As shown, the working principle of the present invention is: the tea leaves to be dedusted are dropped into from the feed pipe 5, and the tea leaves follow the rotation of the spiral blade 12 inside the feed pipe 5 and move to the feed port 16 side. During the movement, Part of the dust on the surface of the tea leaves falls and falls from the filter screen opening 4c to realize the preliminary dedusting of the tea leaves. The inside of the dust removal chamber 9 does not fall, and the suction pipe 11 makes the air body inside the dust removal chamber 9 move upwards, and then drives the dust to rise to the upper end of the dust removal chamber 9, and under the suction of the dust suction pipe 2, the dust passes through the filter screen 10 and then passes through the filter screen 10. The dust suction pipe 2 enters the inside of the dust storage box 3. After a period of dust removal, the wind force of the spiral air duct 8 and the suction pipe 11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com