Novel processing method of radix Szechuan salviae miltiorrhizae

A processing method and technology of salvia miltiorrhiza, applied in the field of danshen industry, can solve the problems of loss of active ingredients, killing of active ingredients, uneven quality of medicinal materials, etc., and achieve the effects of maintaining natural shape, good taste and improving sensory quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

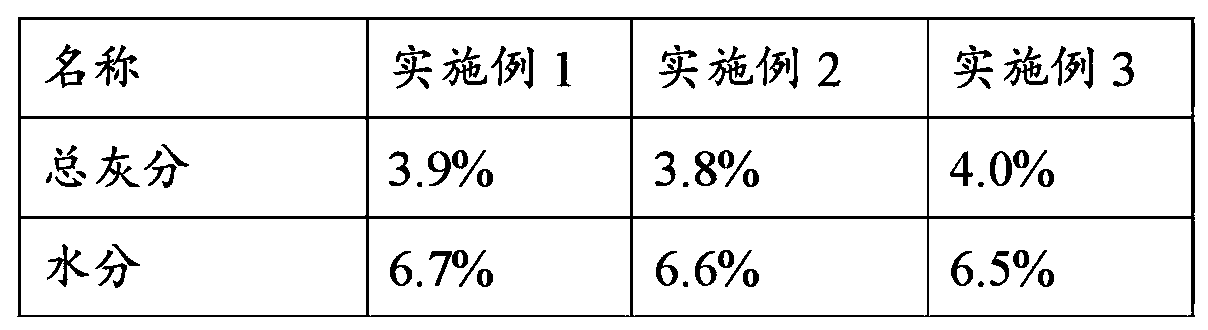

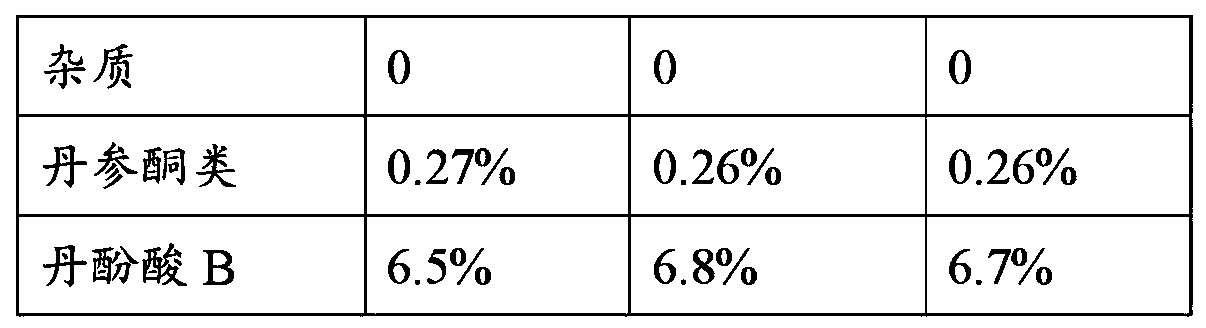

Embodiment 1

[0033] A new processing method of Sichuan salvia miltiorrhiza, comprising the following steps:

[0034] (1) Excavate fresh Zhongjiang Salvia root;

[0035] (2) Select the root strips of Salvia miltiorrhiza; the standard for selecting the root strips of Salvia miltiorrhiza is to select the root strips of salvia miltiorrhiza above the first level, that is, root strips of salvia miltiorrhiza with a diameter between 0.7-1.2cm;

[0036] (3) cleaning;

[0037] (4) Danshen slices are obtained by slicing the cleaned salvia root strips; the cleaned salvia root strips are put into slicer slices, and the thickness of the salvia slices is 1.35mm;

[0038] (6) Freeze-drying the Salvia Miltiorrhiza Tablets;

[0039] (7) Freeze-drying is divided into 17 stages of operation, the first 10 stages are the cooling and freezing stage, and the last 7 stages are the heating stage, combined with vacuum sterilization, the total time-consuming is 60.05 hours; the 17 stages are respectively the first in...

Embodiment 2

[0042] A new processing method of Sichuan salvia miltiorrhiza, comprising the following steps:

[0043] (1) Excavate fresh Zhongjiang Salvia root;

[0044] (2) Select the root strips of Salvia miltiorrhiza; the standard for selecting the root strips of Salvia miltiorrhiza is to select the root strips of salvia miltiorrhiza above the first level, that is, root strips of salvia miltiorrhiza with a diameter between 0.7-1.2cm;

[0045] (3) cleaning;

[0046] (4) Danshen slices are obtained by slicing the cleaned salvia miltiorrhiza roots; the cleaned salvia miltiorrhiza roots are put into a slicer to slice, and the thickness of the salvia miltiorrhiza slices is 1.85mm;

[0047] (6) Freeze-drying the Salvia Miltiorrhiza Tablets;

[0048] (7) Freeze-drying is divided into 17 stages of operation, the first 10 stages are the cooling and freezing stage, and the last 7 stages are the heating stage, combined with vacuum sterilization, the total time-consuming is 75.05 hours; the 17 sta...

Embodiment 3

[0051] A new processing method of Sichuan salvia miltiorrhiza, comprising the following steps:

[0052] (1) Excavate fresh Zhongjiang Salvia root;

[0053] (2) Select the root strips of Salvia miltiorrhiza; the standard for selecting the root strips of Salvia miltiorrhiza is to select the root strips of salvia miltiorrhiza above the first level, that is, root strips of salvia miltiorrhiza with a diameter between 0.7-1.2cm;

[0054] (3) cleaning;

[0055] (4) Danshen slices are obtained by slicing the cleaned salvia miltiorrhiza roots; the cleaned salvia miltiorrhiza roots are put into a slicer to slice, and the thickness of the salvia miltiorrhiza slices is 2.35mm;

[0056] (6) Freeze-drying the Salvia Miltiorrhiza Tablets;

[0057] (7) Freeze-drying is divided into 17 stages of operation, the first 10 stages are cooling and freezing stages, and the last 7 stages are heating stages, combined with vacuum sterilization, the total time-consuming is 90.05 hours; the 17 stages ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com