PI (Proportional-Integral) partition control method for inverter system

A partition control, inverter technology, applied in the output power conversion device, the conversion of AC power input to DC power output, electrical components and other directions, can solve overshoot overshoot or periodic oscillation, slow dynamic response, unable to work stably and other problems, to achieve the effects of fast dynamic response, stable steady-state output, and increased hardware cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

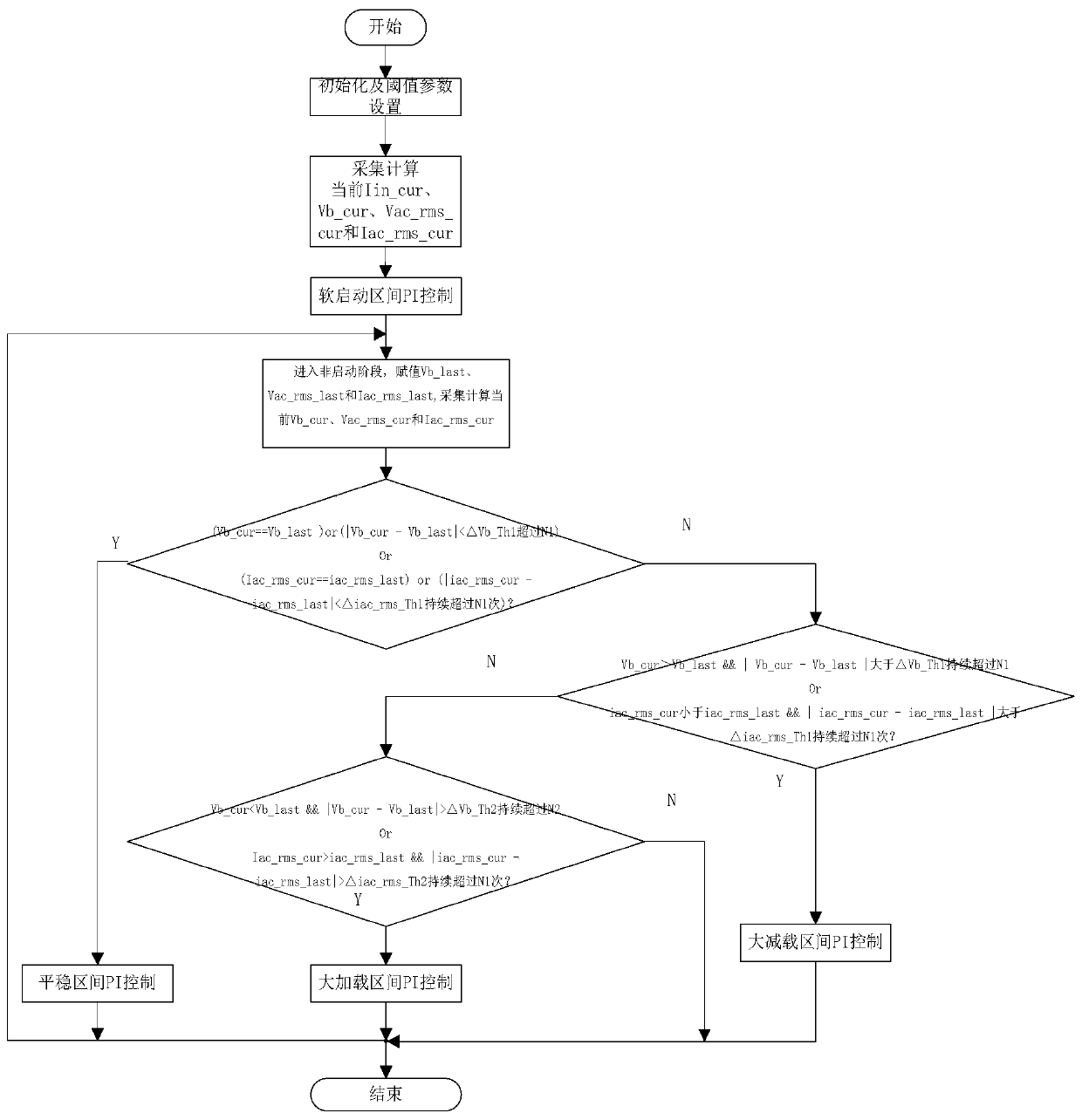

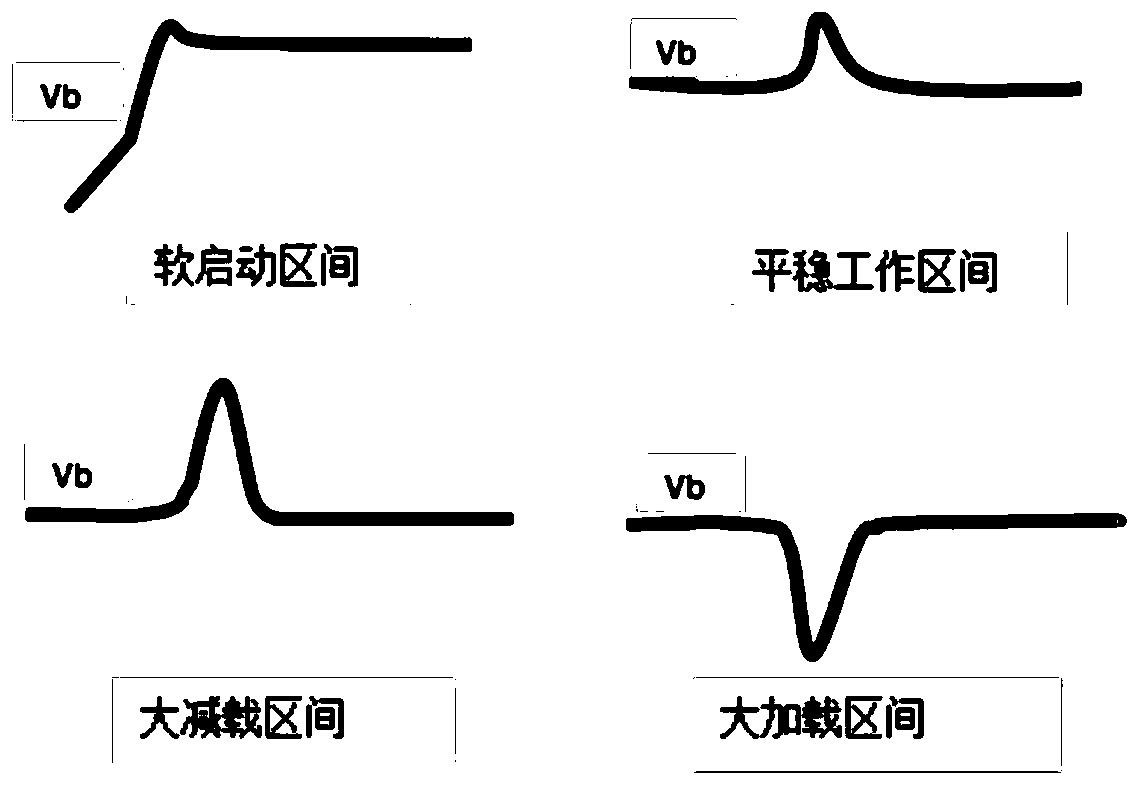

[0024] A PI partition control method for an inverter system, comprising: partitioning the working state of the inverter system, judging the current working state of the inverter system when the inverter system is working, and determining the current working state of the inverter system according to the current state of the inverter system Select the corresponding PI parameter group to control the inverter system.

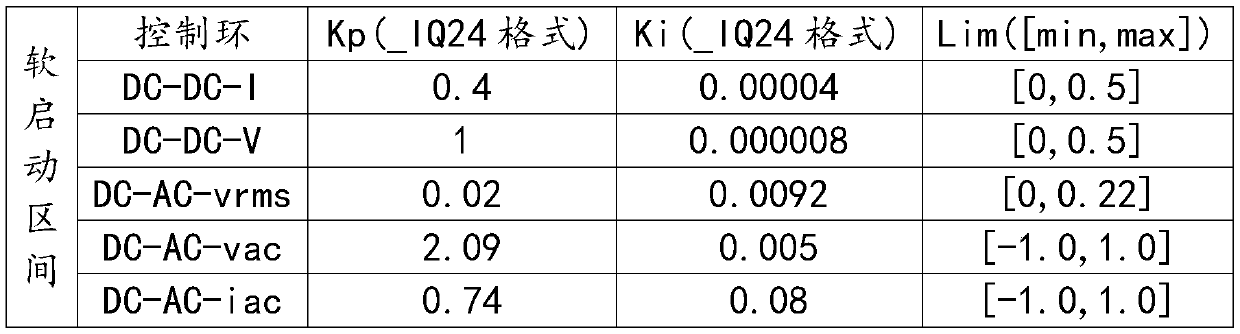

[0025] Specifically, such as figure 1 As shown, this embodiment is aimed at a certain 3KW off-grid inverter with a rated output of 220V, 50H Z Sine wave, the main control chip adopts a 32bit microcontroller of a certain brand, and the PI partition control method of the inverter system includes the following steps:

[0026] 1. After the inverter system completes the initialization and threshold parameter setting, it enters the soft start stage, and obtains the current DC side input current value Iin_cur, bus voltage value Vb_cur, AC side output load voltage value an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com