Lithium ion battery intermediate tab roll core

A lithium-ion battery, intermediate pole technology, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as easy to increase the risk of lithium precipitation, insufficient strength, and increased welding difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

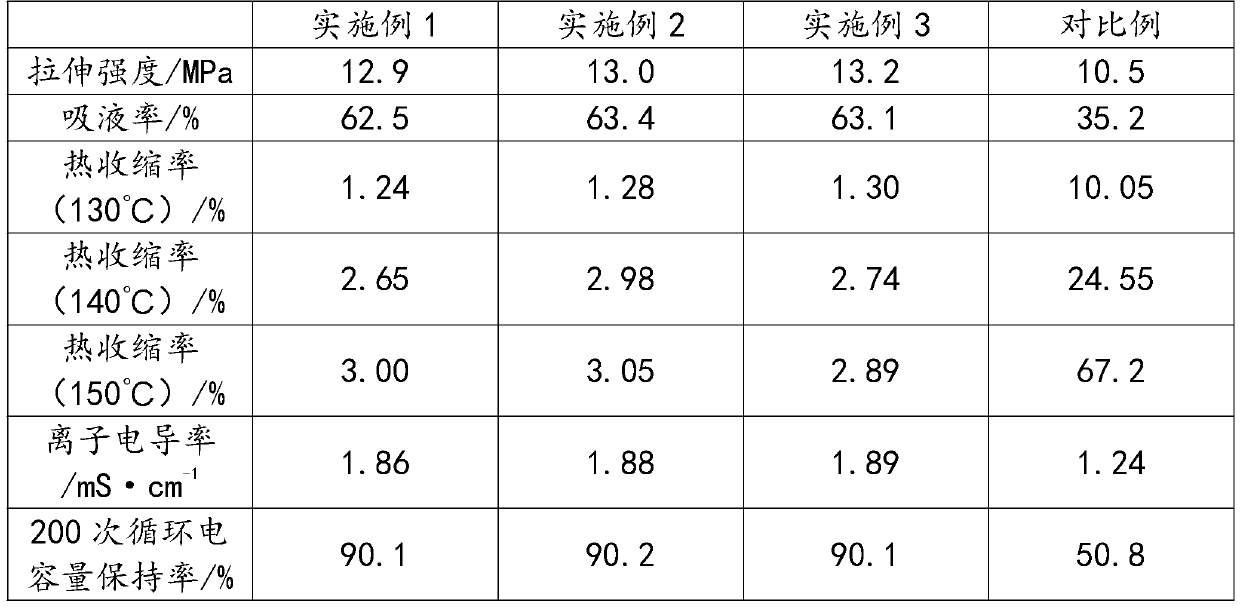

Embodiment 1

[0041] Diaphragm 3 is prepared by the following method:

[0042] Step S1, weigh 2.1g of cellulose acetate and add it to a mixed solvent composed of 8.4mL of N,N-dimethylacetamide and 5.6mL of acetone, stir for 5h to form a uniform slurry, and spin at a spinning rate of 0.4mL / h. Under the condition that the spinning voltage is 10kV, the slurry is electrospun into a film;

[0043] Step S2, soaking the membrane in 0.05mol / L LiOH aqueous solution for 12 hours, washing it with deionized water for 4 times, and drying it in a vacuum oven at 70°C for 10 hours to obtain a cellulose membrane matrix;

[0044] Step S3, add 8.8g of alumina, 0.12g of sodium carboxymethylcellulose and 14g of deionized water into the ball mill, mill for 60min, add 0.9g of acrylate emulsion, stir for 20min, then add 0.02g of fluoropolyether modified Non-toxic polysiloxane, continue to stir for 5 min to obtain a coating;

[0045] Step S4, uniformly coating the paint on one side of the cellulose film substrat...

Embodiment 2

[0047] Diaphragm 3 is prepared by the following method:

[0048] Step S1. Weigh 2.1g of cellulose acetate and add it to a mixed solvent composed of 8.4mL of N,N-dimethylacetamide and 5.6mL of acetone, stir for 5.5h to form a uniform slurry at a spinning rate of 0.4mL / h, under the condition that the spinning voltage is 10kV, the slurry is electrospun into a film;

[0049] Step S2, soaking the membrane in 0.05mol / L LiOH aqueous solution for 12 hours, washing it with deionized water for 5 times, and drying it in a vacuum oven at 70°C for 11 hours to obtain a cellulose membrane matrix;

[0050] Step S3, add 8.8g of alumina, 0.12g of sodium carboxymethylcellulose and 15g of deionized water into the ball mill, mill for 60min, add 0.9g of acrylate emulsion, stir for 25min, then add 0.03g of fluoropolyether modified Non-toxic polysiloxane, continue to stir for 8 min to obtain the coating;

[0051] Step S4, uniformly coating the coating on one side of the cellulose film substrate, c...

Embodiment 3

[0053] Diaphragm 3 is prepared by the following method:

[0054] Step S1. Weigh 2.1 g of cellulose acetate and add it to a mixed solvent composed of 8.4 mL of N,N-dimethylacetamide and 5.6 mL of acetone, and stir for 6 hours to form a uniform slurry. When the spinning rate is 0.4 mL / h. Under the condition that the spinning voltage is 10kV, the slurry is electrospun into a film;

[0055] Step S2, soaking the membrane in 0.05mol / L LiOH aqueous solution for 12 hours, washing it with deionized water for 5 times, and drying it in a vacuum oven at 70°C for 12 hours to obtain a cellulose membrane substrate;

[0056] Step S3, add 8.8g of alumina, 0.12g of sodium carboxymethylcellulose and 16g of deionized water into the ball mill, mill for 60min, add 0.9g of acrylate emulsion, stir for 30min, then add 0.04g of fluoropolyether modified Non-toxic polysiloxane, continue to stir for 10 min to obtain the coating;

[0057] Step S4, uniformly coating the coating on one side of the cellulo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com