Carbon@acrylonitrile-sulfide-based polymer composite cathode active material and preparation method thereof, cathode and preparation method thereof, and application of carbon@acrylonitrile-sulfide-based polymer composite cathode active material in lithium-sulfur battery

A technology for vulcanizing acrylonitrile and acrylonitrile group, applied in battery electrodes, secondary batteries, circuits, etc., to achieve the effect of reducing dosage, improving sulfur loading, and improving contact progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0083] Tapioca starch is used as a carbon source, silica is used as a template, supplemented with conductive carbon black and surfactant polyvinylpyrrolidone, stirred and heated at 80-100°C for 2-6 hours to obtain a slurry, the slurry is first dried and then crushed, and then Carbonize at 800-1300°C, and the carbonized material is crushed again, pickled, washed with water, and dried to obtain a porous carbon material.

[0084] The weight ratio of tapioca starch and silica template is 20-40:80-60;

[0085] Conductive carbon black is 0.5-5% of the weight of biomass carbon source

[0086] The polyvinylpyrrolidone is 0.05-0.5% of the weight of the biomass carbon source.

[0087] The thin-walled porous carbon materials described in the following cases are all prepared by this method unless otherwise stated. Among them, the pore volume of the thin-walled porous carbon material used is 3.6cm 3 / g, the wall thickness is 4nm, the tap density is 0.15g / mL, and the conductivity is 10S / ...

Embodiment 1

[0089] The specific steps are:

[0090] (1) take by weighing 2g acrylonitrile-based polymer (PAN);

[0091] (2) dissolving the acrylonitrile-based polymer in 8g of N-methylpyrrolidone to prepare a polyacrylonitrile solution;

[0092] (3) Dispersing 2g of the thin-walled porous carbon material into the acrylonitrile-based polymer solution to obtain a homogeneous solution;

[0093] (4) drying the solution obtained in step (3) by spray drying at 150° C. to obtain porous carbon-acrylonitrile-based polymer microspheres with a particle size of 20 μm;

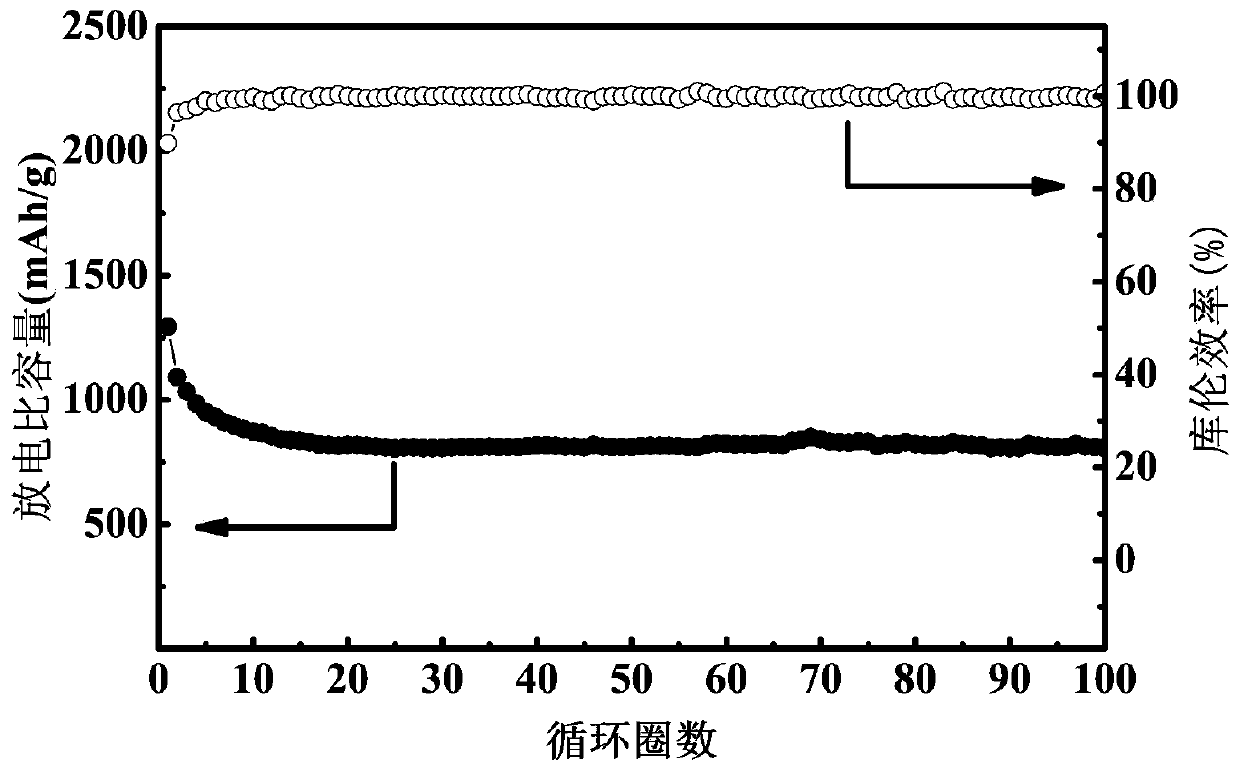

[0094] (5) uniformly mix the porous carbon-acrylonitrile-based polymer microspheres obtained in step (4) with sulfur at a mass ratio of 2:1, and then raise the temperature to 300°C at a heating rate of 2°C / min under the protection of a nitrogen atmosphere, After 2 hours of heat preservation, the carbon@sulfurized acrylonitrile-based polymer composite positive electrode active material was obtained.

[0095] The prepared composite p...

Embodiment 2

[0132] The specific steps are:

[0133] (1) take by weighing 2g acrylonitrile-based polymer (same as embodiment 1);

[0134] (2) Acrylonitrile-based polymer (same as Example 1) is dissolved in the N-methylpyrrolidone of 4g and is mixed with polyacrylonitrile solution;

[0135] (3) Dispersing 2g of the thin-walled porous carbon material into the acrylonitrile-based polymer solution to obtain a homogeneous solution;

[0136] (4) drying the solution obtained in step (3) by spray drying at 100° C. to obtain porous carbon-acrylonitrile-based polymer microspheres with a particle size of 10 μm;

[0137] (5) Evenly mix the porous carbon-acrylonitrile-based polymer microspheres obtained in step (4) with sulfur at a mass ratio of 1:1, then heat-treat under the protection of a nitrogen atmosphere, and heat up to 360 °C at a heating rate of 3 °C / min. ℃, heat preservation for 3 hours, and the carbon@sulfurized acrylonitrile-based polymer composite positive electrode active material was o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com