Gear contact fatigue life prediction method based on load spectrum

A contact fatigue and life prediction technology, applied in instruments, complex mathematical operations, calculations, etc., can solve the problem of not considering the multi-axial stress state, and achieve the effect of saving test costs, improving accuracy, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0026] Such as figure 1 Shown, the present invention comprises the following steps:

[0027] Step 1. Compile the load spectrum for the finite load-time history obtained from the measurement. Based on the statistical results of the rainflow counting method, use the parameter extrapolation method to perform function fitting on the load of the entire life cycle to obtain the second load of the entire life cycle. dimensional load spectrum;

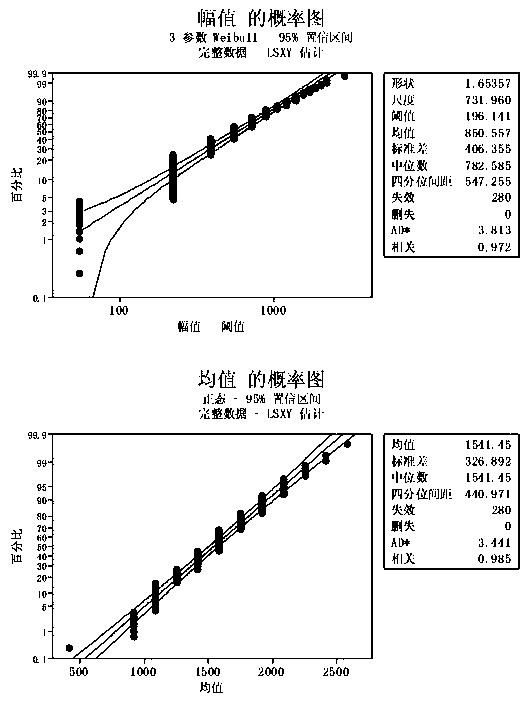

[0028] Step 1.1. Perform rainflow counting processing on the load-time history, remove small loads, divide the loads into a rainflow matrix with an amplitude-average value of 20×20, and obtain the frequency relationship between the average load value and the load amplitude value.

[0029] Taking the automobile reducer as an example:

[0030] Perform rainflow counting processing on the load-time history at the output end, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com