Efficient cement grinding aid

A cement grinding aid and high-efficiency technology, applied in the field of high-efficiency cement grinding aids, can solve the problems of corrosion of steel bars, affecting the service life and durability of concrete, and high potential safety hazards, so as to increase the compressive strength and improve the effect of grinding. , the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

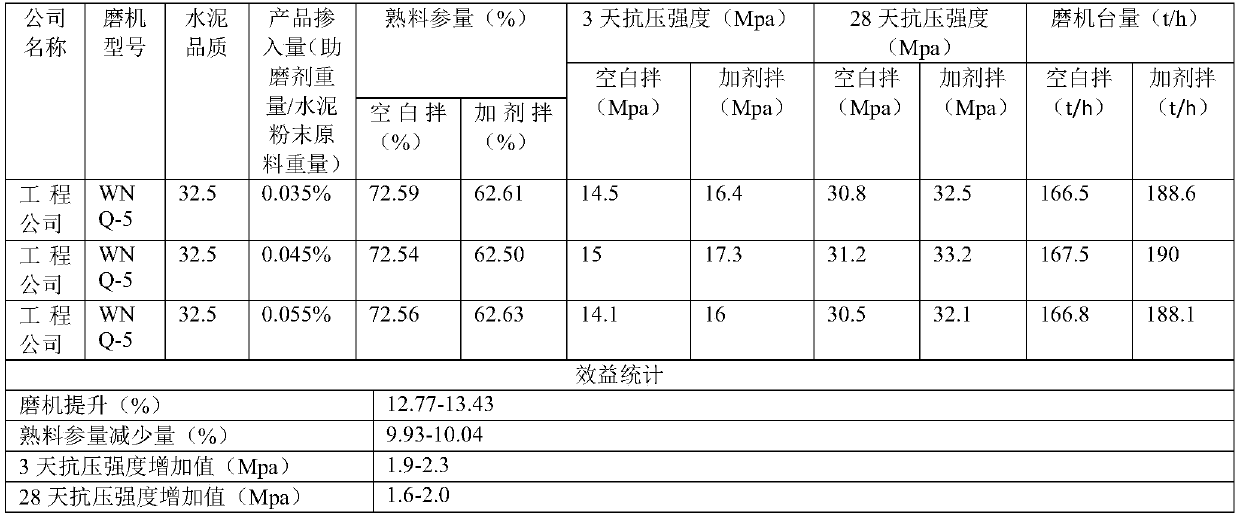

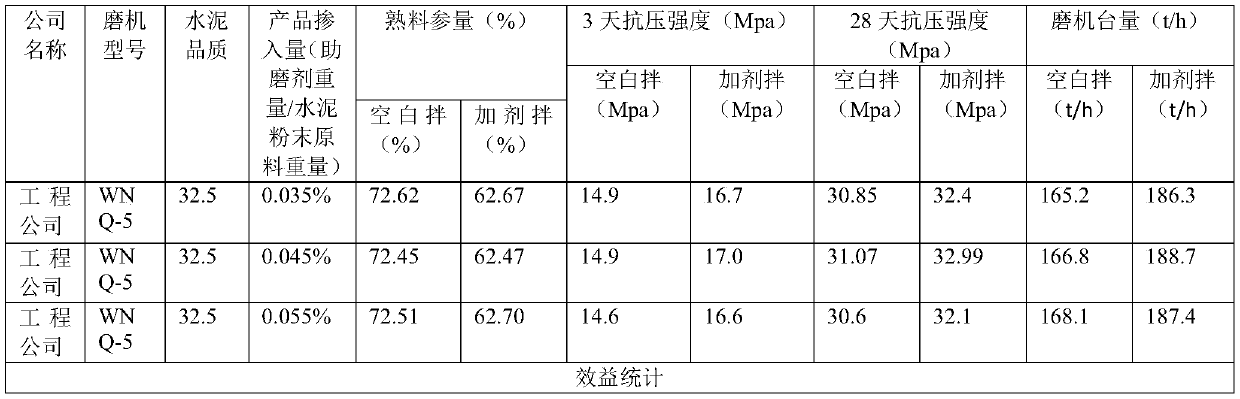

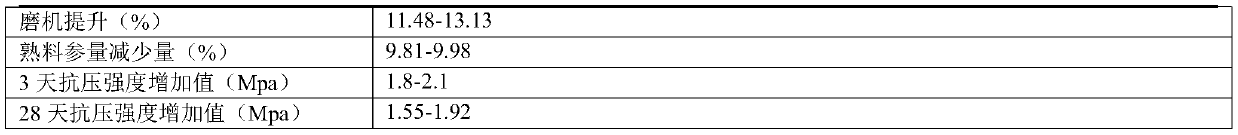

Examples

Embodiment 1

[0024] The present embodiment provides a kind of efficient cement grinding aid, comprises the component of following percentage by weight:

[0025] Modified triethanolamine 30%, triisopropanolamine 22%, modified glycerol 33%, modified molasses 5%, sodium thiocyanate 3.5%, expanded perlite 0.5%, cocamidopropyl betaine 3 %, calcium lignin sulfonate 3%.

[0026] In the above formula, the preparation method of the modified triethanolamine is: mix triethanolamine and maleic anhydride in a molar ratio of 2:1, and add 2% by weight of p-toluenesulfonic acid, and mix it uniformly again. Place it at 115° C. for 2.5 h to obtain triethanolamine maleate, and finally prepare triethanolamine maleate into an aqueous solution with a volume concentration of 50% with distilled water.

[0027] The preparation method of the modified glycerol is as follows: first mix glycerin and formic acid in a molar ratio of 1:1.2, then add 0.5% volume of sulfuric acid, mix again, and finally place it at 85°C f...

Embodiment 2

[0039] The present embodiment provides a kind of efficient cement grinding aid, comprises the component of following percentage by weight:

[0040] Modified triethanolamine 25%, triisopropanolamine 20%, modified glycerol 35%, modified molasses 6%, sodium thiocyanate 3.3%, expanded perlite 0.7%, cocamidopropyl betaine 5 %, calcium lignin sulfonate 5%.

[0041]In the above formula, the preparation method of the modified triethanolamine is: mix triethanolamine and maleic anhydride in a molar ratio of 2:1, and add 2% by weight of p-toluenesulfonic acid, and mix it uniformly again. Place it at 110° C. for 3 h to obtain triethanolamine maleate, and finally prepare triethanolamine maleate into an aqueous solution with a volume concentration of 50% with distilled water.

[0042] The preparation method of the modified glycerol is as follows: first mix glycerin and formic acid in a molar ratio of 1:1.2, then add 0.5% volume of sulfuric acid, mix again, and finally place it at 80°C for ...

Embodiment 3

[0055] The present embodiment provides a kind of efficient cement grinding aid, comprises the component of following percentage by weight:

[0056] Modified triethanolamine 35%, triisopropanolamine 25%, modified glycerol 30%, modified molasses 4%, sodium thiocyanate 2%, expanded perlite 0.3%, cocamidopropyl betaine 1.9 %, Calcium lignin sulfonate 1.8%.

[0057] In the above formula, the preparation method of the modified triethanolamine is: mix triethanolamine and maleic anhydride in a molar ratio of 2:1, and add 2% by weight of p-toluenesulfonic acid, and mix it uniformly again. Place it at 120° C. for 2 h to obtain triethanolamine maleate, and finally use distilled water to prepare triethanolamine maleate into an aqueous solution with a volume concentration of 50%.

[0058] The preparation method of the modified glycerol is as follows: first mix glycerin and formic acid in a molar ratio of 1:1.2, then add 0.5% volume of sulfuric acid, mix again, and finally place it at 90°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com