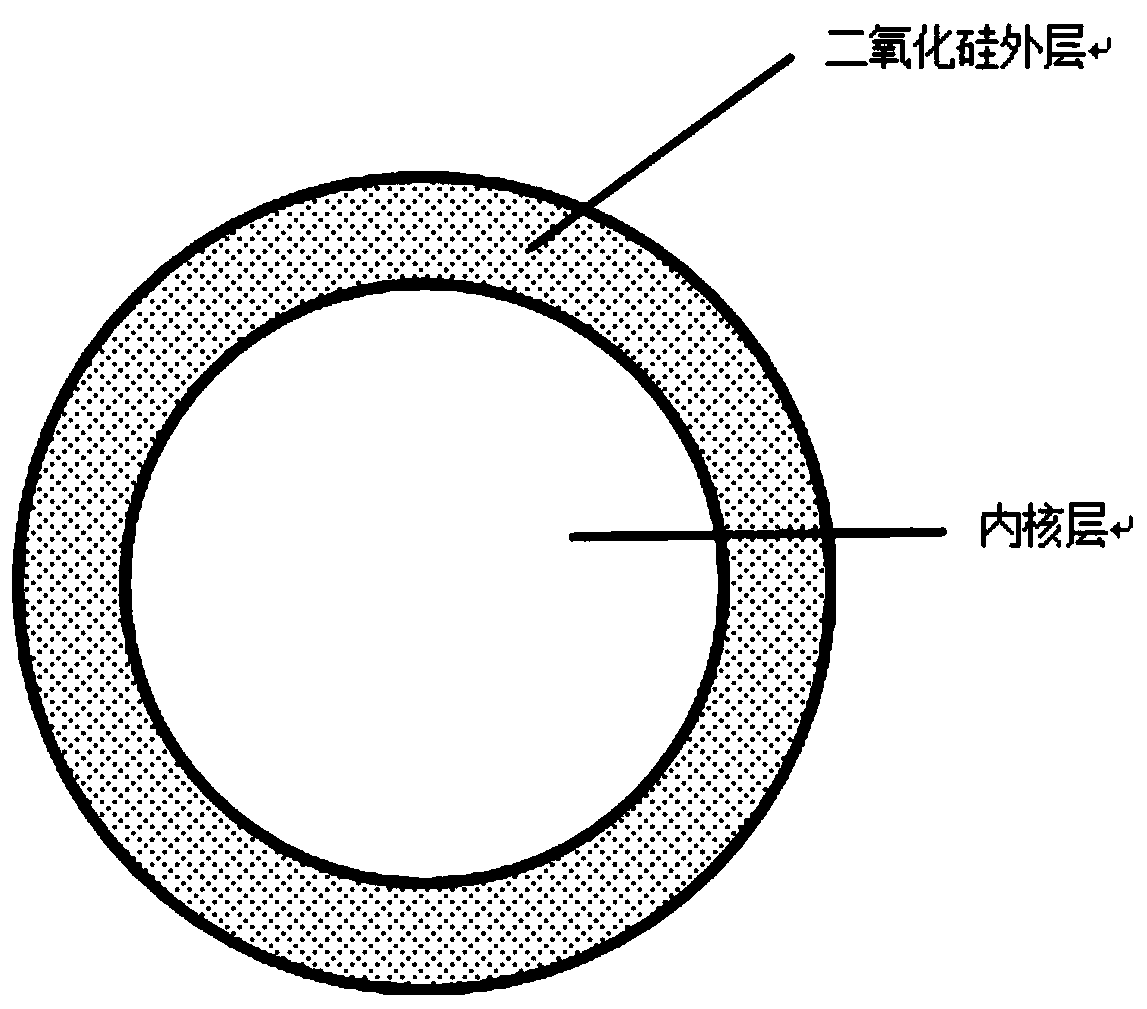

City domestic sewage purifier and preparation method thereof

A technology of urban domestic sewage and purifiers, applied in chemical instruments and methods, separation methods, water/sewage treatment, etc., can solve problems such as complex operation, high treatment cost, and unsatisfactory treatment efficiency, and achieve increased specific surface area, Efficient purification effect, improvement of treatment efficiency and treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

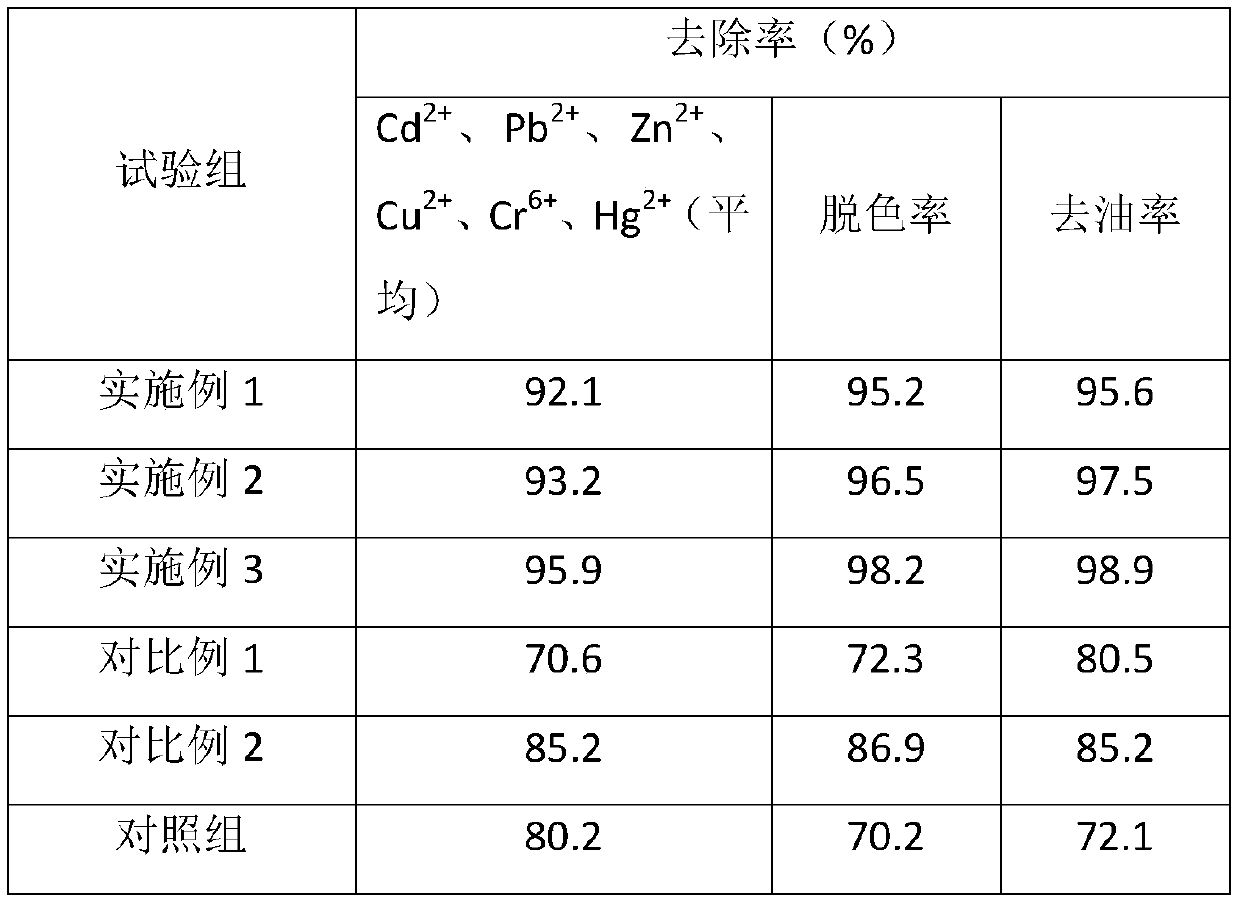

Embodiment 1

[0025] A purifying agent for urban domestic sewage, comprising the following components and parts by weight: 80 parts of modified diatomite, 30 parts of activated carbon, 30 parts of silicon dioxide powder, 10 parts of sodium aluminate, 10 parts of fly ash, flocculation 10 parts of agent and 5 parts of synergist.

[0026] The modified diatomite is prepared by the following method: (1) Add diatomite to 0.1mol / l hydrochloric acid according to the solid-to-liquid ratio of 1:10, stir and heat at 85°C for 12h, use Washed with deionized water for 3 times, then placed in a muffle furnace and calcined at 250°C for 3 hours, cooled to room temperature and crushed to 100 mesh to obtain pretreated diatomite; (2) chitosan, pretreated diatomite Add it into 2% acetic acid solution according to the weight ratio of 2:1 and stir evenly. The amount of acetic acid added is twice the mass of the mixed solids, and the stirring time is 4 hours. Finally, use 1mol / l sodium hydroxide solution to adjust...

Embodiment 2

[0038] A purifying agent for urban domestic sewage, comprising the following components and parts by weight: 100 parts of modified diatomite, 40 parts of activated carbon, 40 parts of silica powder, 15 parts of sodium aluminate, 10 parts of fly ash, flocculation 10 parts of agent and 5 parts of synergist.

[0039]The modified diatomite is prepared by the following method: (1) Add diatomite to 0.1mol / l hydrochloric acid according to the solid-to-liquid ratio of 1:10, stir and heat at 85°C for 12h, use Washed with deionized water for 4 times, then placed in a muffle furnace and calcined at 250°C for 3h, cooled to room temperature and crushed to 100 mesh to obtain pretreated diatomite; (2) chitosan, pretreated diatomite Add it into 2% acetic acid solution according to the weight ratio of 2:1 and stir evenly. The amount of acetic acid added is twice the mass of the mixed solids, and the stirring time is 4 hours. Finally, use 1mol / l sodium hydroxide solution to adjust the pH of the...

Embodiment 3

[0052] A purifying agent for urban domestic sewage, comprising the following components and parts by weight: 120 parts of modified diatomite, 50 parts of activated carbon, 50 parts of silicon dioxide powder, 20 parts of sodium aluminate, 20 parts of fly ash, flocculation 20 parts of agent, 10 parts of synergist.

[0053] The modified diatomite is prepared by the following method: (1) Add diatomite to 0.1mol / l hydrochloric acid according to the solid-to-liquid ratio of 1:10, stir and heat at 85°C for 12h, use Washed with deionized water for 5 times, then placed in a muffle furnace and calcined at 250°C for 3h, cooled to room temperature and crushed to 100 mesh to obtain pretreated diatomite; (2) chitosan, pretreated diatomite Add it into 2% acetic acid solution according to the weight ratio of 2:1 and stir evenly. The amount of acetic acid added is twice the mass of the mixed solids, and the stirring time is 4 hours. Finally, use 1mol / l sodium hydroxide solution to adjust the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com