Preparation method of efficient formaldehyde adsorption material based on activated carbon

A formaldehyde adsorption and activated carbon technology is applied in the field of preparation of high-efficiency formaldehyde adsorption materials to achieve the effects of improving adsorption, increasing specific surface area and improving adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

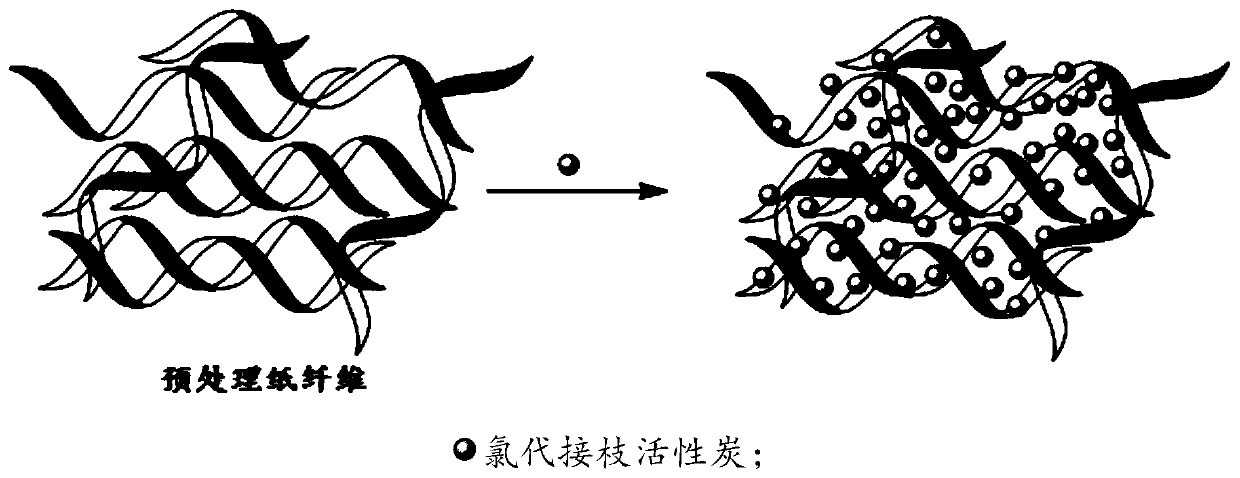

Image

Examples

Embodiment 1

[0021] The specific preparation process of the graft modifier is as follows: add 6.18kg ethanolamine to 10LN, N-dimethylformamide, add 20.1kg triethylamine to it at the same time, and add 26.16kg di-tert-butyl dicarbonate Esters, stirred for 10-15 minutes, heated to 50-60°C for reflux for 10-12 hours, then added the product into water, extracted with ethyl acetate, dried the oil phase with sodium sulfate, evaporated and concentrated, and then added petroleum ether Recrystallization was carried out to obtain the grafted modifier.

[0022] The specific preparation process of oxidized activated carbon is as follows:

[0023] Extract 1.2kg of activated carbon in 10L of acetone solution for 3-4h, and then dry it in an oven at 100-110°C. At the same time, add 1kg of the dried activated carbon into 1L of nitric acid solution with a concentration of 56%, and raise the temperature to 80- Reflux and stir at 85°C for 3-5h, filter and wash until neutral, then dry in an oven at 100-110°C ...

Embodiment 2

[0025] The specific preparation process of oxidized activated carbon is as follows:

[0026]Extract 1.2kg of activated carbon in 10L of acetone solution for 3-4h, and then dry it in an oven at 100-110°C. At the same time, add 1kg of the dried activated carbon into 1L of 30% nitric acid solution and raise the temperature to 80- Reflux and stir at 85°C for 3-5h, filter and wash until neutral, then dry in an oven at 100-110°C to obtain oxidized activated carbon.

Embodiment 3

[0028] The specific preparation process of oxidized activated carbon is as follows:

[0029] Extract 1.2kg of activated carbon in 10L of acetone solution for 3-4h, and then dry it in an oven at 100-110°C. Reflux and stir at 85°C for 3-5h, filter and wash until neutral, then dry in an oven at 100-110°C to obtain oxidized activated carbon.

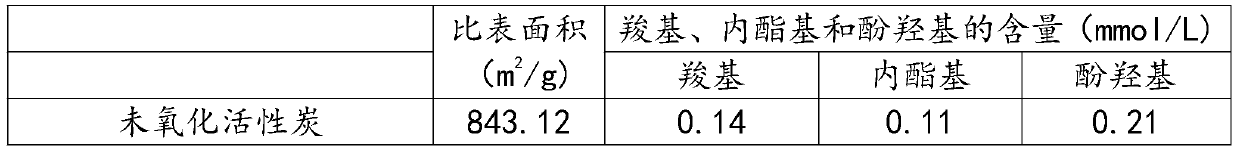

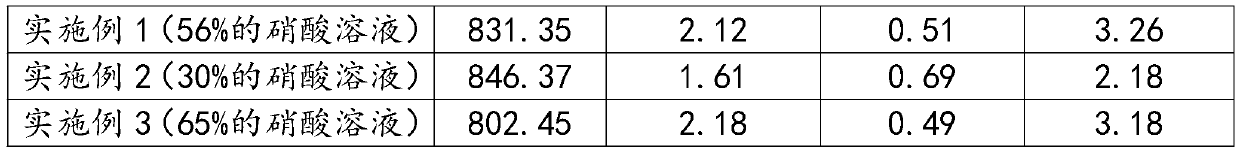

[0030] Adopt gas adsorption method to measure the specific surface area of the oxidized activated carbon prepared in embodiment 1-3, adopt Boehm titration to measure the content of carboxyl, lactone group and phenolic hydroxyl in the oxidized activated carbon simultaneously, the results are as shown in table 1:

[0031] The specific surface area and the content of carboxyl group, lactone group and phenolic hydroxyl group of the oxidized activated carbon prepared in the embodiment 1-3 of table 1 and unoxidized activated carbon

[0032]

[0033]

[0034] It can be seen from Table 1 that the specific surface area of activated carbon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com