Application of a kind of inhibitor aa/amps in positive flotation demagnesization of phosphate rock

A technology of inhibitor and phosphate rock, which is applied in flotation, solid separation, etc., can solve the difficulty of flotation and separation of apatite and dolomite, restrict the comprehensive development and utilization of high magnesium phosphate rock, and treat acid-containing wastewater from tailings Difficulty and other problems, to achieve good selective inhibition, good industrial feasibility, and eliminate corrosion maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

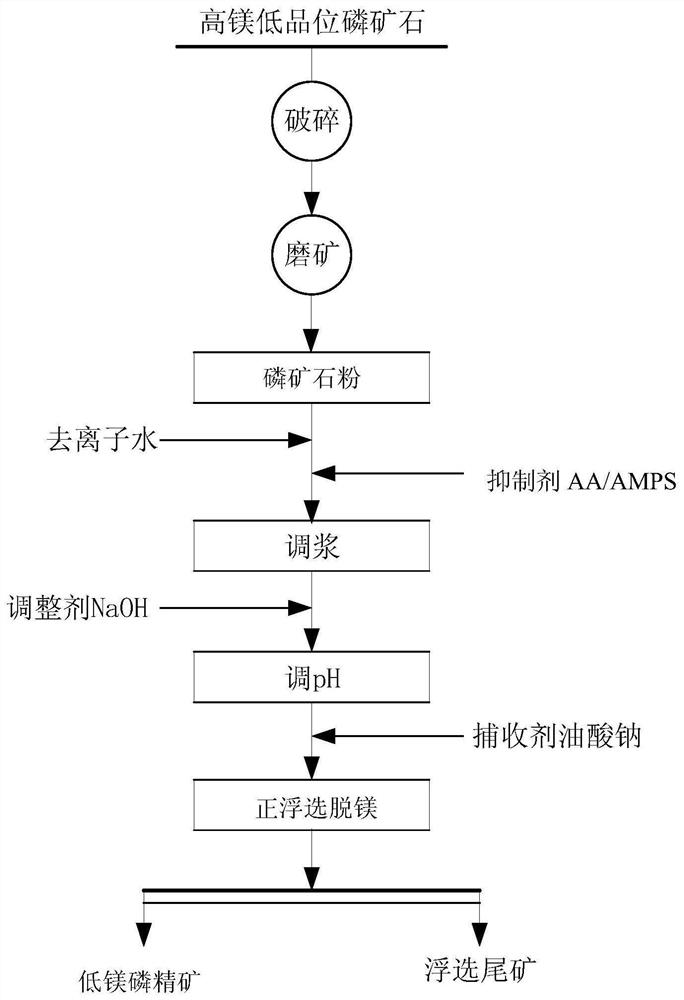

[0037] The application of a kind of inhibitor AA / AMPS in the positive flotation magnesification of phosphate rock, the process flow chart of its implementation is shown in figure 1 , including the following operation process of positive flotation magnesium removal of high-magnesium and low-grade phosphate rock:

[0038] Step 1: Crushing and Grinding

[0039] Crushing and ball milling high-magnesium and low-grade phosphate rock to obtain phosphate rock powder; wherein, in the phosphate rock powder, the mass of the phosphate rock powder smaller than 74 μm accounts for 75% of the total mass of the phosphate rock powder;

[0040] Step 2: Blending

[0041] Put the phosphate rock powder in the XFG single-cell flotation machine, adjust the speed of the XFG single-cell flotation machine to 1700rpm, add deionized water and the inhibitor AA / AMPS solution, and stir and mix evenly, and carry out slurry mixing for 3 minutes. Obtain phosphate rock slurry; wherein, in the phosphate rock slur...

Embodiment 2

[0049] The application of an inhibitor AA / AMPS in positive flotation magnesification of phosphate rock, specifically includes the following operation process of positive flotation magnesification of high-magnesium and low-grade phosphate rock:

[0050] Step 1: Crushing and Grinding

[0051] Crushing and ball milling high-magnesium and low-grade phosphate rock to obtain phosphate rock powder; wherein, in the phosphate rock powder, the mass of phosphate rock powder particles smaller than 74 μm accounts for 80% of the total mass of the phosphate rock powder;

[0052] Step 2: Blending

[0053] Put the phosphate rock powder in the XFG single-cell flotation machine, adjust the speed of the XFG single-cell flotation machine to 1900rpm, add deionized water and the inhibitor AA / AMPS solution, and stir and mix evenly, and carry out slurry mixing for 3 minutes. Obtain phosphate rock slurry; wherein, in the phosphate rock slurry, the mass percentage concentration of phosphate rock is 20%...

Embodiment 3

[0061] The application of an inhibitor AA / AMPS in positive flotation magnesification of phosphate rock, specifically includes the following operation process of positive flotation magnesification of high-magnesium and low-grade phosphate rock:

[0062] Step 1: Crushing and Grinding

[0063] Crushing and ball milling high-magnesium and low-grade phosphate rock to obtain phosphate rock powder; wherein, in the phosphate rock powder, the mass of phosphate rock powder particles smaller than 74 μm accounts for 80% of the total mass of the phosphate rock powder;

[0064] Step 2: Blending

[0065] Put the phosphate rock powder in the XFG single-tank flotation machine, adjust the speed of the XFG single-tank flotation machine to 2100rpm, add deionized water and inhibitor AA / AMPS solution, stir and mix evenly, and perform slurry mixing for 3 minutes. Obtain phosphate rock slurry; wherein, in the phosphate rock slurry, the mass percentage concentration of phosphate rock is 25%, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com