A fixture for segmental circulation of ships and its method for segmental circulation of ships

A fixture and ship technology, applied in the direction of berths, dry docks, ship parts, etc., can solve the problems of high precision requirements for pillar-type pier, large contact surface between portal frame and segmented structure, and reduce the payload of the board car. Achieve the effect of light weight, flexible design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

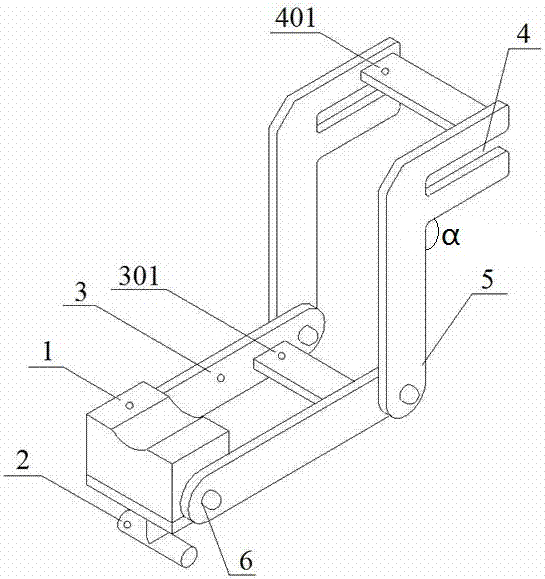

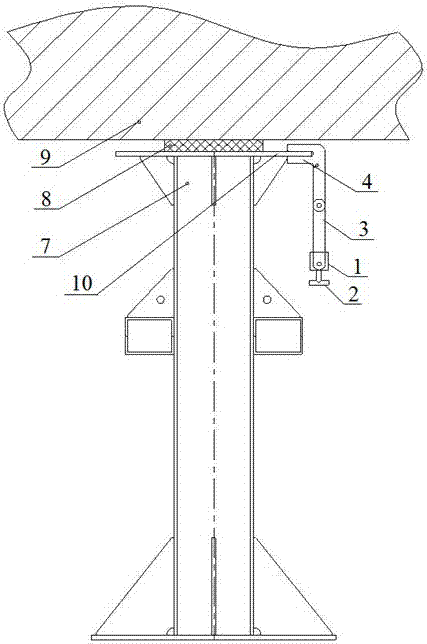

[0042] Such as figure 1 , figure 2 and image 3 As shown, the fixture of the segmental circulation of the ship in this embodiment is used for the segmental circulation of the ship in this embodiment. The clamp includes a magnet block 1, a switch handle 2 for controlling magnetism, a set of chucks and a set of connecting rods 3, The chuck includes a clamping joint 4 and a connecting arm 5, the clamping joint 4 is provided with a bayonet 401, the connecting end of the connecting arm 5 is movably connected with one end of the connecting rod through a connecting hole, the other end of the connecting rod 3 One end is connected with the magnet block 1.

[0043] In this embodiment, a set of collets includes two parallel collets, and the clip joints 4 of the two parallel collets are connected through the first reinforcing plate 402 to form an H-shaped structure. In the set of connecting rods It includes two connecting rods parallel to each other. The two connecting rods parallel t...

Embodiment 2

[0056] In this embodiment, the included angle α between the clip joint 4 and the connecting arm 5 of the fixture is 30°, 45°, 60°, 80° or any value of 30°-90°, so as to achieve a better snap connection For purpose, design according to circumstances, and all the other technical solutions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com