Filter medium for removing arsenic from drinking water and preparation method thereof

A filter medium and drinking water technology, applied in the field of water treatment, can solve problems such as secondary pollution, discounted amount of arsenic removal, and reduced effectiveness, and achieve strong adsorption capacity, easy to use, and high-efficiency removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

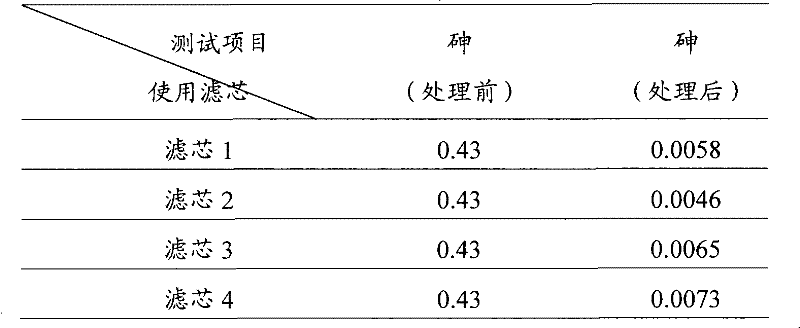

Examples

Embodiment 1

[0027] (1) Take ultra-high molecular weight polyethylene powder 275g, this ultra-high molecular weight polyethylene is the M-II type product of the Second Auxiliary Factory of Beijing Dongfang Petrochemical Co., Ltd., and the weight-average molecular weight is 2,500,000;

[0028] (2) Weigh 75g of medical activated carbon powder, the particle size of the medical activated carbon powder is 94μm~115μm, and the specific surface area is greater than 1400m 2 / g;

[0029] (3) Weighing 45g of goethite powder, the particle size of the goethite powder is 65 μm to 85 μm;

[0030] (4) Weighing 50g of pyrolusite powder, the particle diameter of the pyrolusite powder is 65 μm~85 μm;

[0031] (5) Weigh 80 g of red mud powder, the particle size of which is 62 μm to 85 μm;

[0032] (6) Take food-grade ammonium bicarbonate 95g, the purity of described food-grade ammonium bicarbonate is greater than 99.99%;

[0033] (7) Put the above six powders into a mechanical stirrer and stir for 10 minut...

Embodiment 2

[0037] (1) Take ultra-high molecular weight polyethylene powder 290g, this ultra-high molecular weight polyethylene is the M-II type product of the Second Auxiliary Factory of Beijing Dongfang Petrochemical Co., Ltd., and the weight average molecular weight is 2.5 million;

[0038] (2) Weigh 75g of medical activated carbon powder, the particle size of the medical activated carbon powder is 94μm~115μm microns, and the specific surface area is greater than 1400m 2 / g;

[0039] (3) Weighing 45g of goethite powder, the particle size of the goethite powder is 65 μm to 85 μm;

[0040] (4) Weighing 40g of pyrolusite powder, the particle diameter of the pyrolusite powder is 65 μm~85 μm;

[0041] (5) Weigh 75 g of red mud powder, the particle size of which is 62 μm to 85 μm;

[0042] (6) Take food-grade ammonium bicarbonate 95g, the purity of described food-grade ammonium bicarbonate is greater than 99.99%;

[0043] (7) Put the above six powders into a mechanical stirrer and stir fo...

Embodiment 3

[0047] (1) Take ultra-high molecular weight polyethylene powder 260g, this ultra-high molecular weight polyethylene is the M-II type product of Beijing Dongfang Petrochemical Co., Ltd. Auxiliary No. 2 Factory, and the weight-average molecular weight is 2,500,000;

[0048] (2) Weigh 90g of medical activated carbon powder, the particle size of the medical activated carbon powder is 94μm~115μm, and the specific surface area is greater than 1400m 2 / g;

[0049] (3) Weigh 40 g of goethite powder, the particle size of which is 65 μm to 85 μm;

[0050] (4) Weighing 50g of pyrolusite powder, the particle diameter of the pyrolusite powder is 65 μm~85 μm;

[0051] (5) Weigh 75 g of red mud powder, the particle size of which is 62 μm to 85 μm;

[0052] (6) Take by weighing food-grade ammonium bicarbonate 105g, the purity of described food-grade ammonium bicarbonate is greater than 99.99%;

[0053] (7) Put the above six powders into a mechanical stirrer and stir for 10 minutes to mix e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com