Production system of round cotton balls and method for preparing cotton balls by using same

A production system and technology of cotton balls, which are applied in the direction of medical equipment, pharmaceutical equipment, and other medical equipment, etc., can solve problems such as easy loosening and cotton balls with many fluffs, and achieve the problem of many fluffs, uniform tightness, and good product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

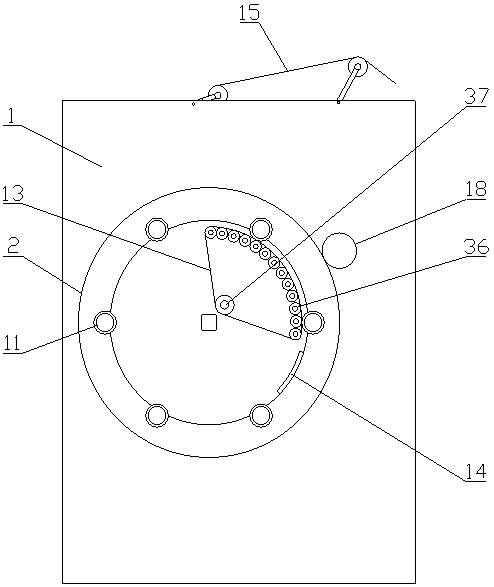

[0044] see Figure 1-8 , the embodiment of the present invention provides a production system for round cotton balls, the system includes a vertically arranged processing table 1 and a sliver fixed-length conveying device 38, a ball rolling device and a cotton ball Collecting devices etc., the processing table 1 is arranged along the left and right directions, and the sliver fixed-length conveying device 38 sends the sliver 15 of a certain length to the ball rolling device for rounding, and the cotton ball 39 output by the ball rolling device falls into the cotton ball collecting device.

[0045] Among them, see Figure 1-8 The ball rolling device in this embodiment includes a circular turntable 2, a plurality of winding heads 3 arranged on the circular turntable 2 along the front and rear directions, a winding needle 4 that is arranged on the front end of the winding head 3 along the front and rear directions and can be stretched back and forth, The circular channel 5 in the...

Embodiment 2

[0063] The embodiment of the present invention also provides a method for preparing cotton balls using the production system for round cotton balls provided in Example 1, the method comprising:

[0064] (1) Before each winding head 3 rotates from the upper end of the rounding channel 5, two pairs of traction rollers send the sliver 15 of a certain length to the upper end of the rounding channel 5 along the vertical direction and tear it off.

[0065] (2) When the winding head 3 turns to the upper end of the rounding channel 5; the winding needle 4 has stretched out and rotated, and its front end is in contact with the upper part of the sliver 15 to push the sliver 15 into the rounding channel 5; the winding needle 4 is in the rounding channel 5 Rotation rounds the sliver 15 to obtain the cotton ball 39. In this step, glue can be added after the cotton ball is basically formed, which further solves the problem that the cotton ball has a lot of fluff and is easy to loosen.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com