A Method for Fabricating Microstructured Piezoelectric Energy Harvesters Based on Dissolvable Molds

A microstructured, piezoelectric energy harvesting technology, which is applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., can solve the problem of high cost, inability to process three-dimensional complex structures, It takes a long time for precision molds to achieve the effect of improving output performance, low cost, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] A method for preparing a microstructured piezoelectric sensor based on micro-stereolithography, comprising the following steps:

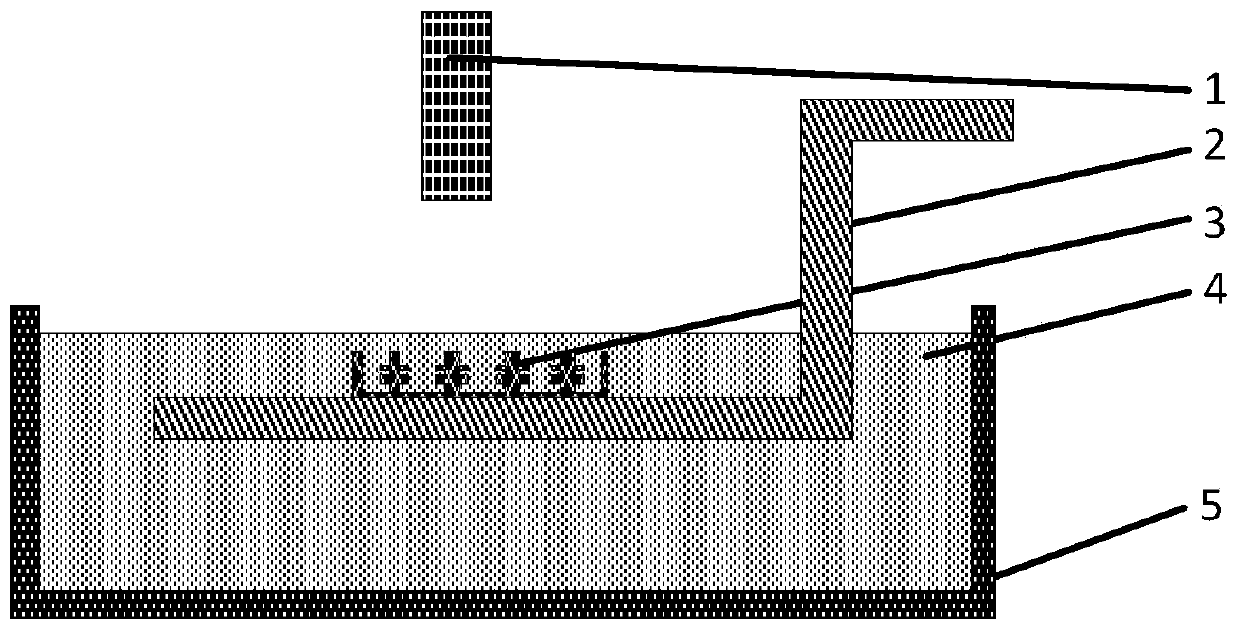

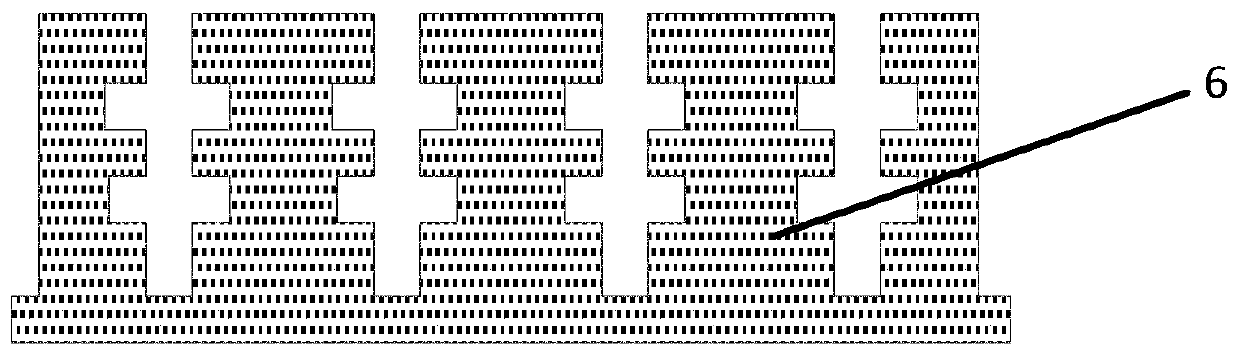

[0026] The first step, the preparation of the soluble mold 3: put the soluble photosensitive resin 4 into the resin tank 5, adjust the lifting of the printing platform 2 immersed in the soluble photosensitive resin 4 to control the thickness of the printing layer, and use the ultraviolet light 1 to expose for layered curing and print The layer thickness is 0.04mm, the bottom layer is 1-3 layers, the exposure time of the bottom layer is 6s, and the exposure time of the subsequent single layer is 1-2s, and the microstructured soluble mold 3 is prepared, such as figure 1 shown;

[0027] The second step, the preparation of the composite piezoelectric material 9: mixing and dispersing the piezoelectric material and the organic matrix, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com