Low junction capacitance characteristic terahertz Schottky diode and manufacturing method thereof

A low junction capacitance and diode technology, applied in the field of low junction capacitance terahertz Schottky diodes and their fabrication, can solve problems such as low cutoff frequency of Schottky diodes, and achieve the effect of small device capacitance and high cutoff frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

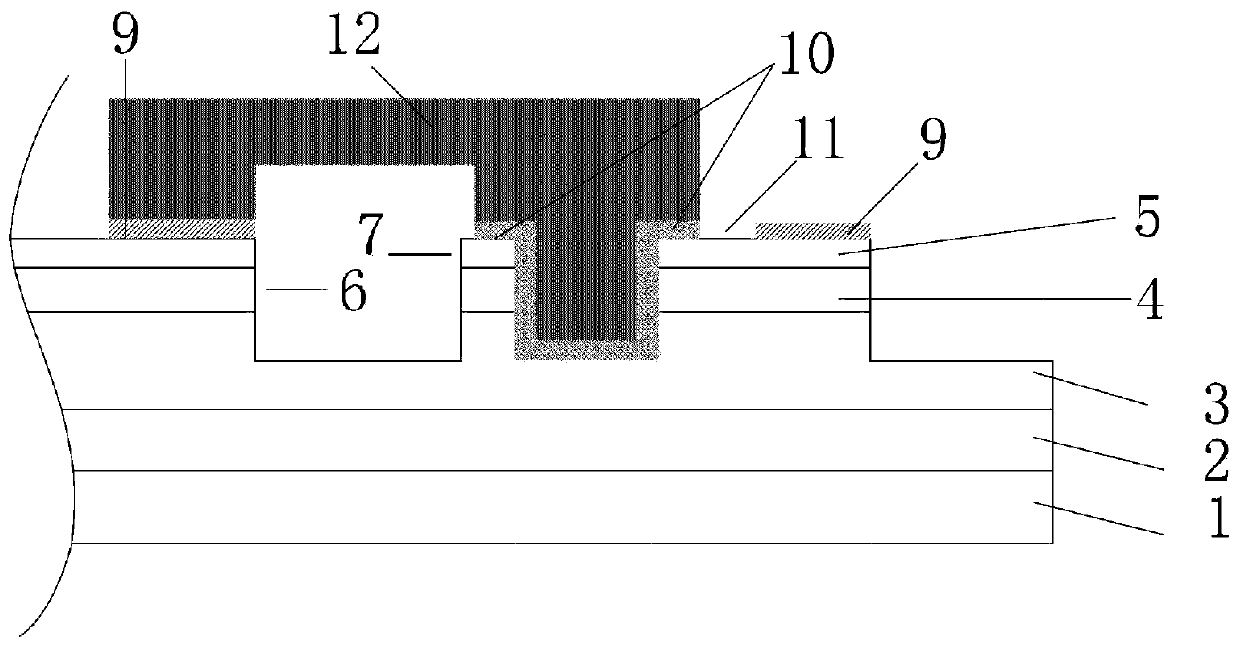

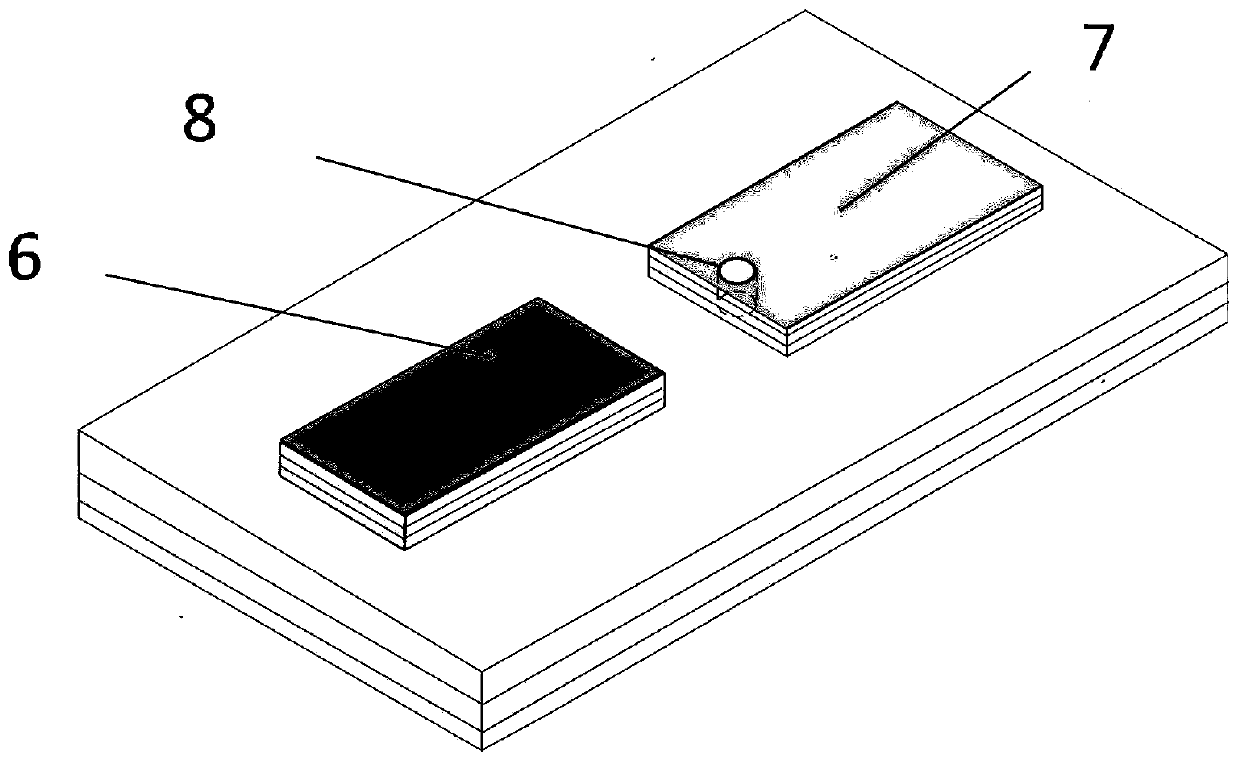

[0064] Such as Figure 1-Figure 6 As shown, a terahertz Schottky diode device with low junction capacitance characteristics, wherein, from bottom to top, there are substrate 1, stress buffer layer 2, gallium nitride GaN channel layer 3, aluminum gallium nitride AlGaN potential Barrier layer 4, gallium nitride GaN cap layer 5; there are two convex surfaces (first convex surface 7 and second convex surface 6) on the gallium nitride GaN channel layer 3, and the convex surface includes part of the gallium nitride GaN channel layer 3 and aluminum gallium nitride AlGaN barrier layer 4 and gallium nitride GaN capping layer 5; there is a cylindrical hole 8 on the surface of the first convex surface 7, and the depth is consistent with the height of the convex surface; two layers of different Schottky metals 10 and The ohmic contact metal 9, the Schottky metal 10 is separated from the ohmic contact metal 9 by a channel 11; the Schottky contact metal 10 leads out a hollow air bridge 12 i...

Embodiment 2

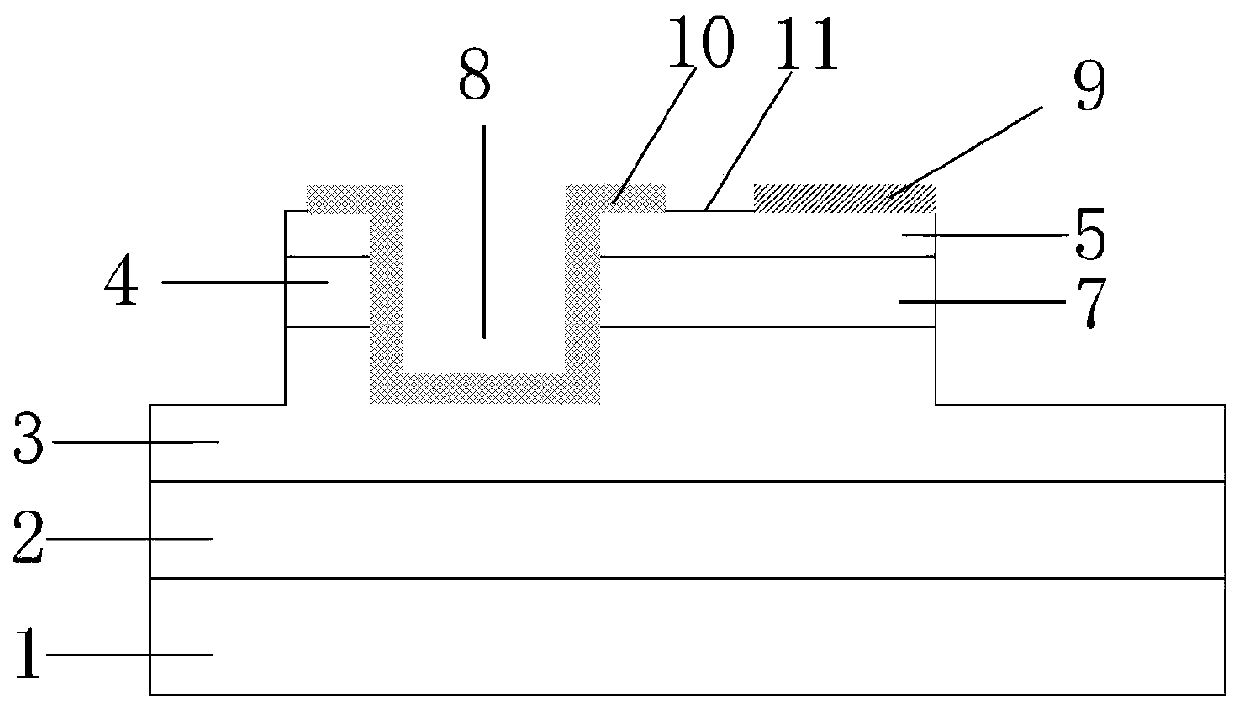

[0066] This embodiment is similar to embodiment 1, as Figure 7 As shown, the difference is that the Schottky metal 10 is made on the sidewall of AlGaN / GaN and on GaN. The process can be achieved, and it is also the performance to achieve low junction capacitance.

[0067] Compared with the prior art, the beneficial effect is: the present invention provides a terahertz Schottky diode with low junction capacitance characteristics and its manufacturing method, further, the Schottky contact metal 10 is nickel metal. There are two parts of capacitance in the contact between metal and material. Under zero bias, one is the capacitance that exists when the metal is in contact with the surface of the material, and this part of capacitance is relatively large; the other is when the metal is in contact with the two-dimensional electron gas. The Schottky junction formed between the materials has a depletion effect on the two-dimensional electron gas. There is a certain distance between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com