Preparation method and application of bismuth molybdate/boron nitrogen doped graphene photoelectric functional material

A photoelectric functional material and application technology, applied in chemical instruments and methods, material electrochemical variables, molybdenum compounds, etc., can solve the problems of large instruments, complicated operation, time-consuming, etc., and achieve the effect of short cycle and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

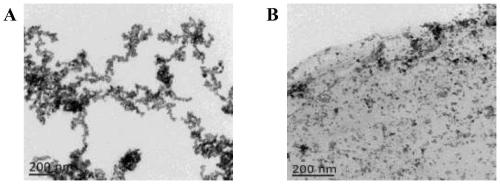

[0033] (1) Bi 2 MoO 6 / Preparation of BNG Photoelectric Functional Materials

[0034] 0.2425 g of bismuth nitrate pentahydrate and 0.065 g of sodium molybdate dihydrate were respectively dissolved in 5 mL of ethanol solution and vigorously stirred at 60°C. Next, the sodium molybdate dihydrate solution was added dropwise to the bismuth nitrate pentahydrate solution under magnetic stirring and named solution A.

[0035]Then, 25 mg of graphene oxide powder and 100 mg of ammonium pentaborate were dispersed in 10 mL of ethanol solution to obtain a homogeneous solution and named solution B.

[0036] Afterwards, solution B was slowly added dropwise to solution A, and kept stirring for 1 h. Finally, the mixed solution was transferred to a stainless steel autoclave at 160 ° C for 24 hours; cooled to room temperature, centrifuged, washed with deionized water and ethanol three times each; after drying, Bi 2 MoO 6 / BNG photoelectric functional materials.

[0037] (2) Construction of...

Embodiment 2

[0047] (1) Bi 2 MoO 6 / Preparation of BNG Photoelectric Functional Materials

[0048] 0.2425 g of bismuth nitrate pentahydrate and 0.065 g of sodium molybdate dihydrate were respectively dissolved in 5 mL of ethanol solution and vigorously stirred at 40°C. Next, the sodium molybdate dihydrate solution was added dropwise to the bismuth nitrate pentahydrate solution under magnetic stirring and named solution A.

[0049] Then, 25 mg of graphene oxide powder and 100 mg of ammonium pentaborate were dispersed in 10 mL of ethanol solution to obtain a homogeneous solution and named solution B.

[0050] Afterwards, solution B was slowly added dropwise to solution A, and kept stirring for 0.5 h. Finally, the mixed solution was transferred to a stainless steel autoclave at 140 ° C for 20 h; cooled to room temperature, centrifuged, washed with deionized water and ethanol three times each; after drying, Bi 2 MoO 6 / BNG photoelectric functional materials.

[0051] (2) Construction of ...

Embodiment 3

[0056] (1) Bi 2 MoO 6 / Preparation of BNG Photoelectric Functional Materials

[0057] 0.2425 g of bismuth nitrate pentahydrate and 0.065 g of sodium molybdate dihydrate were respectively dissolved in 5 mL of ethanol solution and vigorously stirred at 80°C. Next, the sodium molybdate dihydrate solution was added dropwise to the bismuth nitrate pentahydrate solution under magnetic stirring and named solution A.

[0058] Then, 25 mg of graphene oxide powder and 100 mg of ammonium pentaborate were dispersed in 10 mL of ethanol solution to obtain a homogeneous solution and named solution B.

[0059] Afterwards, solution B was slowly added dropwise to solution A and kept stirring for 2 h. Finally, the mixed solution was transferred to a stainless steel autoclave at 180°C for 12 hours; cooled to room temperature, centrifuged, washed with deionized water and ethanol three times each; after drying, Bi 2 MoO 6 / BNG photoelectric functional materials.

[0060] (2) Construction of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com