Gas chamber structure for gas sensing and manufacturing method of gas chamber structure

A technology of gas sensing and gas chamber, which is applied in the field of gas sensing, can solve problems such as inability to miniaturize, single material, and difficulty in coupling, and achieve the effects of poor mechanical properties, excessive volume, and easy miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

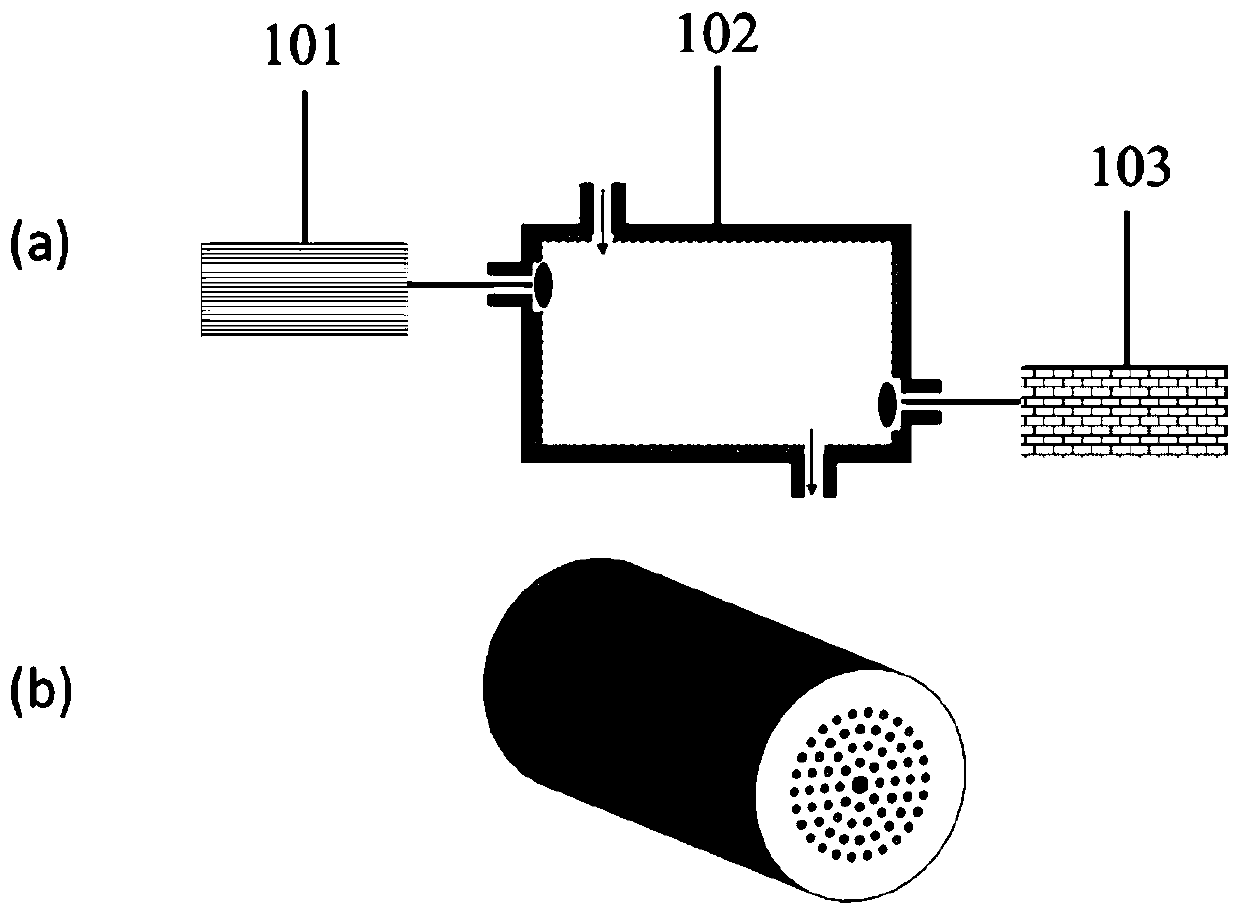

[0047] In the real-time example 1 of the present invention, a gas chamber structure for gas sensing is firstly provided, which includes:

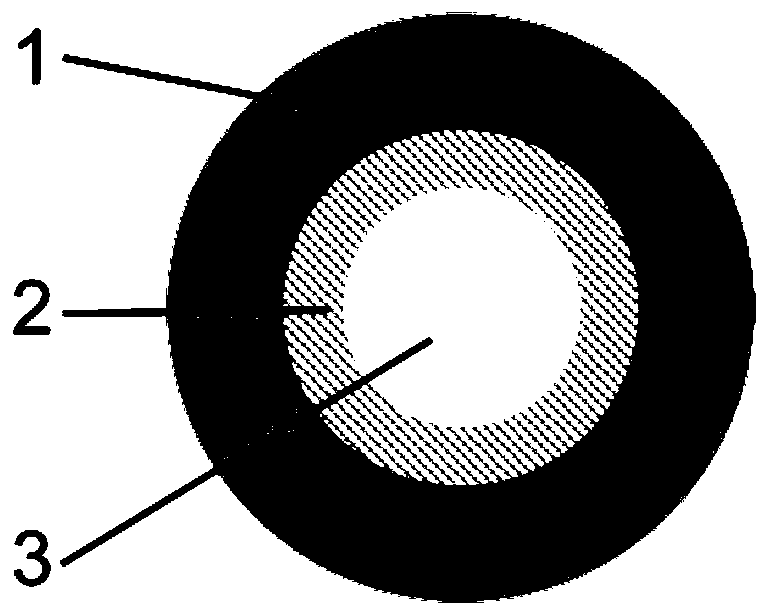

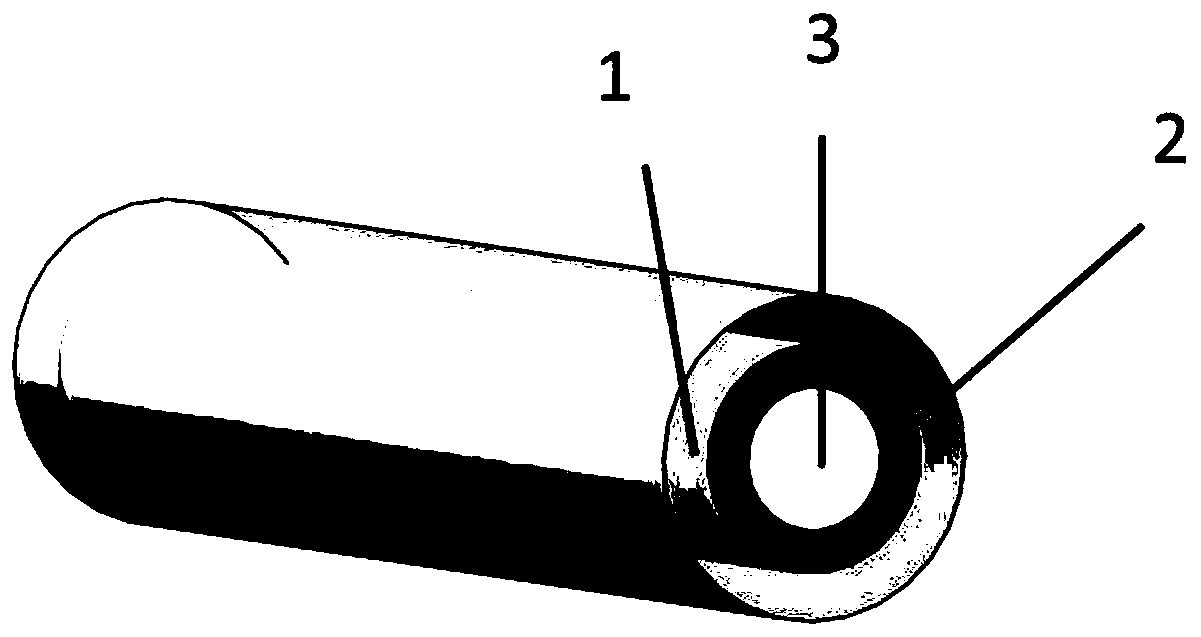

[0048] The outermost polymer PPSU outer cladding is used to provide sufficient mechanical support for the entire fiber. The omnidirectional reflection layer connected with the polymer outer cladding is used to confine the transmitted laser light in the fiber core. The air core located in the innermost layer is a hollow core structure, which is used to provide transmission channels for gas and laser.

[0049] The polymer outer cladding material is PPSU, which has good tensile properties and flexibility, and the thickness of PPSU is 500 μm. The omnidirectional reflection layer structure is a multi-material dielectric reflection structure. Multi-material dielectric reflection structure made of PPSU and As 2 Se 3 Alternate composition, PPSU and As 2 Se 3 With similar thermodynamic properties, PPSU and As 2 Se 3 The refractive index diff...

Embodiment 2

[0059] In the real-time example 2 of the present invention, a gas chamber structure for gas sensing is firstly provided, which includes:

[0060] The outermost layer of UV-cured resin is used to provide sufficient mechanical support for the entire fiber. The omnidirectional reflection layer connected with the outer cladding is used to confine the transmitted laser light in the fiber core. The air core located in the innermost layer is a hollow core structure, which is used to provide transmission channels for gas and laser.

[0061] The polymer outer cladding material is an ultraviolet curing resin with good tensile properties and flexibility, and the thickness of the polymer material is 900 μm. The omnidirectional reflection layer structure is a multi-material dielectric reflection structure, and the multi-material dielectric reflection structure is composed of PPSU and As 2 Se 3 Alternate composition, PPSU and As 2 Se 3 With similar thermodynamic properties, the PPSU an...

Embodiment 3

[0071] In the real-time example three of the present invention, a gas chamber structure for gas sensing is firstly provided, which includes:

[0072] The outermost layer of polymer UV-cured resin is used to provide sufficient mechanical support for the entire fiber. The omnidirectional reflection layer connected with the polymer outer cladding is used to confine the transmitted laser light in the fiber core. The air core located in the innermost layer is a hollow structure, which is used to provide transmission channels for gas and laser.

[0073] The polymer outer cladding material is an ultraviolet curing resin with good tensile properties and flexibility, and the thickness of the polymer material is 20 μm. The omnidirectional reflection layer structure is a multi-material dielectric reflection structure, and the multi-material dielectric reflection structure is composed of PPSU and As 2 Se 3 Alternate composition, PPSU and As 2 Se 3 With similar thermodynamic propertie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com