Double-sided sawtooth scraper for fabricated building and method for wall brick thin pasting

A kind of construction and prefabricated technology, which is applied in the direction of construction, building structure, covering/lining, etc., can solve the problems of reduced room use area, thick and hollow wall bricks, and slow construction speed, so as to improve construction efficiency and stick The effect of high brick flatness and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

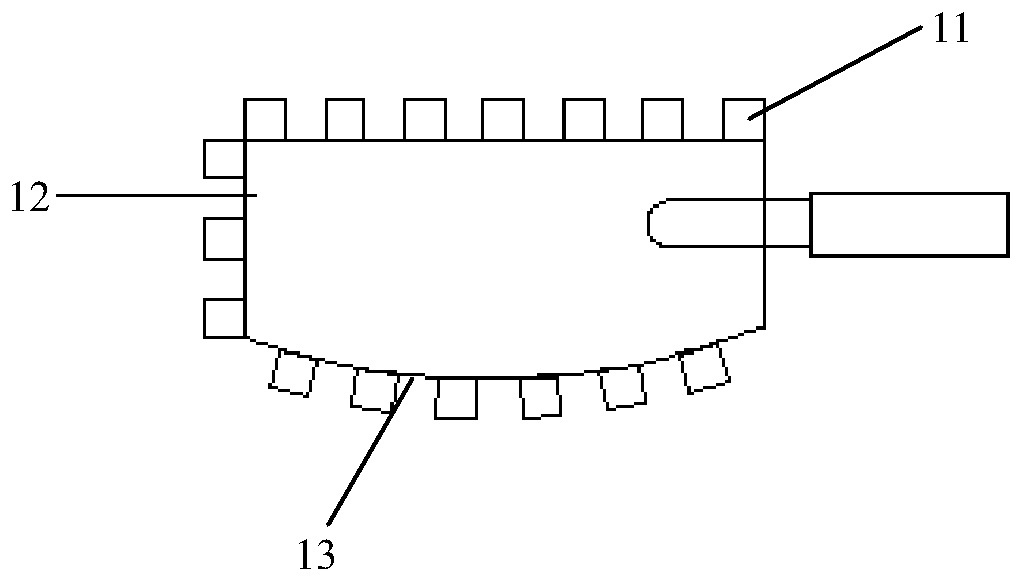

[0029] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

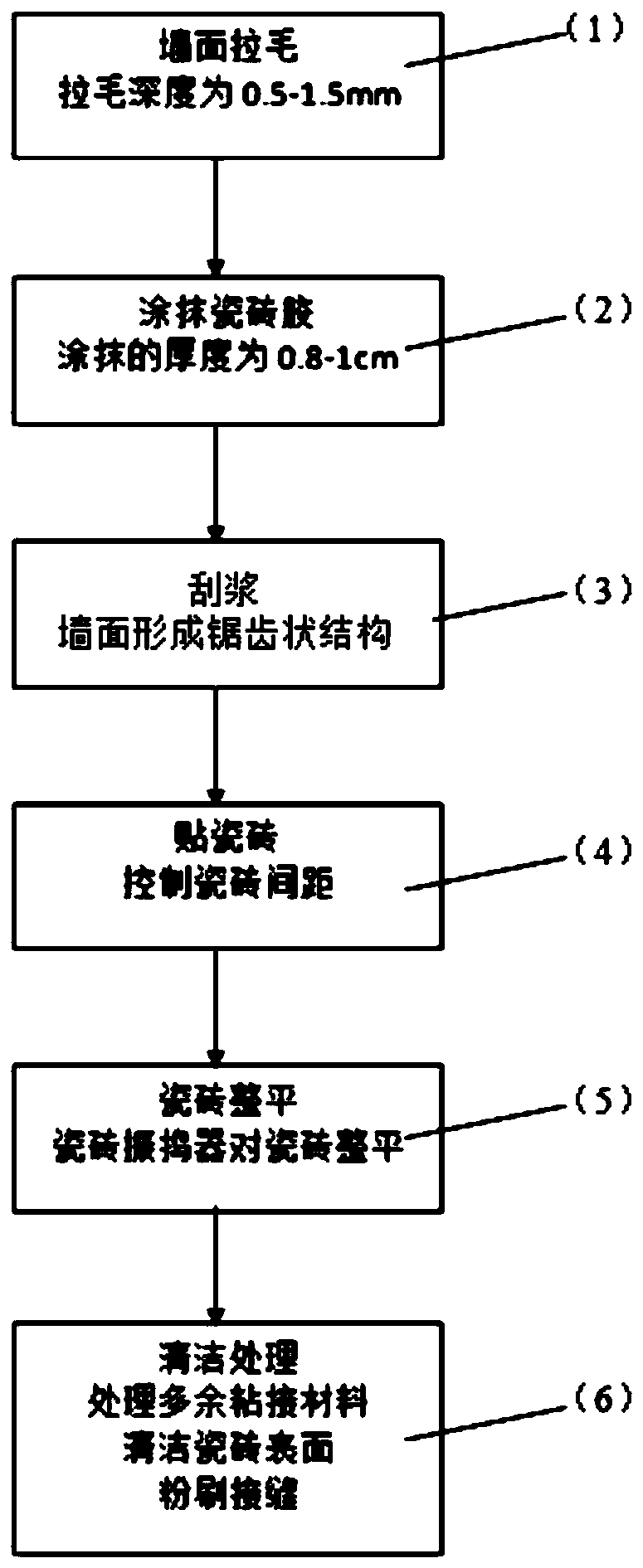

[0030] Such as figure 1 Shown, a kind of prefabricated building is used wall brick thin pasting method, comprises the following steps:

[0031] (1) Brushing the wall

[0032] Use a high-pressure water gun to aim at the wall for roughening. The roughening depth is 0.5-1.5mm. Use the cutting force of 190-230MPa high-pressure water to impact and cut the concrete wall to make the wall rough; The method of pulling down is used to form a relatively regular longitudinal hair-tooth edge; it can also be pulled from left to right to form a relatively regular horizontal hair-tooth edge; it can also be pulled in an oblique manner to form Relatively regular oblique burrs;

[0033] (2) Apply tile adhesive

[0034] Apply tile adhesive on the already brushed wall surface, the thickness of the application is 0.8-1cm, the water ratio of the tile adhesive is 1: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com